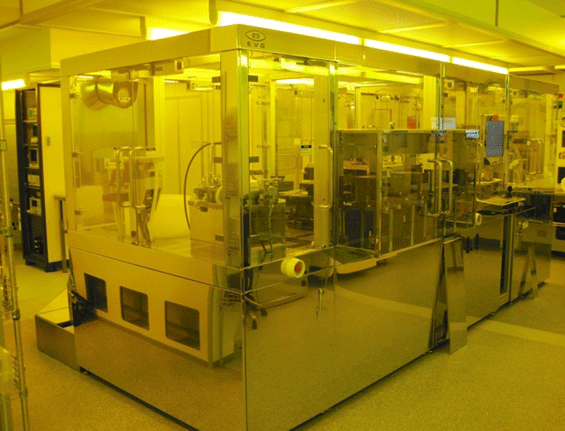

Used EVG / EV GROUP Gemini #9038329 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9038329

Wafer Size: 8"

Vintage: 2010

Wafer bonder, up to 8"

Currently configured to 6"

For high volume production applications

(1) universal wafer bond chamber with top & bottom side heaters

(1) low temp plasma bonding module

(2) gas lines with flow controllers

(1) high frequency RF generator

(1) low frequency RF generator

Cleaning station for fusion bonding preparation

Megasonic spray cleaner

Chemistry cabinet for up to (2) chemicals

(4) Bond chucks

Automatic alignment

Robotic handling between cassette and alignment stage

Robotic handling between aligner and bonder

Send, receive and reject cassette stations

Fully motorized smartview splitfield microscope for double side viewing

Pressure bonding capability: 40KN

Integrated cooling station for high throughput

Max temperature: 550°C

(2) Edwards xds-10 vacuum pumps

Neslab system II chiller

System computer with windows MS OS

Raid hard drive system

Wafer id reader

Operations manual

2010 vintage.

EVG / EV GROUP Gemini is a flexible bonder, designed for advanced materials processing and the high-volume manufacturing of optoelectronic devices. It is a fully automated system that is capable of bonding a variety of materials, including metals, ceramics, and organic materials. EVG Gemini features a "cut & cut" configuration, which allows for a variety of bonding techniques to be applied. This means that the bonder is capable of cutting, welding, and bonding materials in a single process. EV GROUP Gemini comes with a compact design, making it ideal for applications in technology-driven industries that require minimal workspace. The system uses video microscopy for disease analysis and high accuracy by providing reliability and repeatability, increasing throughput and maximizing yields. The bonder is also equipped with a range of advanced features, including four-axis motion, force feedback, and a large working area. The four-axis motion feature lets the bonder perform multiple processes with precision and speed. The force feedback enables precise control of the bond forces in order to ensure optimal bonding results. There is also a built-in, large-diameter force control wheel that makes setup, control, and controlling the bond process a breeze. Gemini has an advanced split-level sub-stage that can vary the bond height to accommodate different applications. This allows for a wide range of materials to be bonded, such as transparent, colored, and indirect-combination substrates. The built-in wafer chuck enables the bonder to accommodate large wafer sizes, while an integrated nanopositioner makes it easy to align the substrate perfectly. EVG / EV GROUP Gemini bonder is perfect for direct and indirect-combination bonding processes, and enables high-accuracy and consistency in the bonding operation. The bonder can also be used for multi-bond applications and its programming features allow complete control over the process. Furthermore, the bonder is designed to be easily integrated into an existing production line and is capable of handling a wide range of materials and applications.

There are no reviews yet