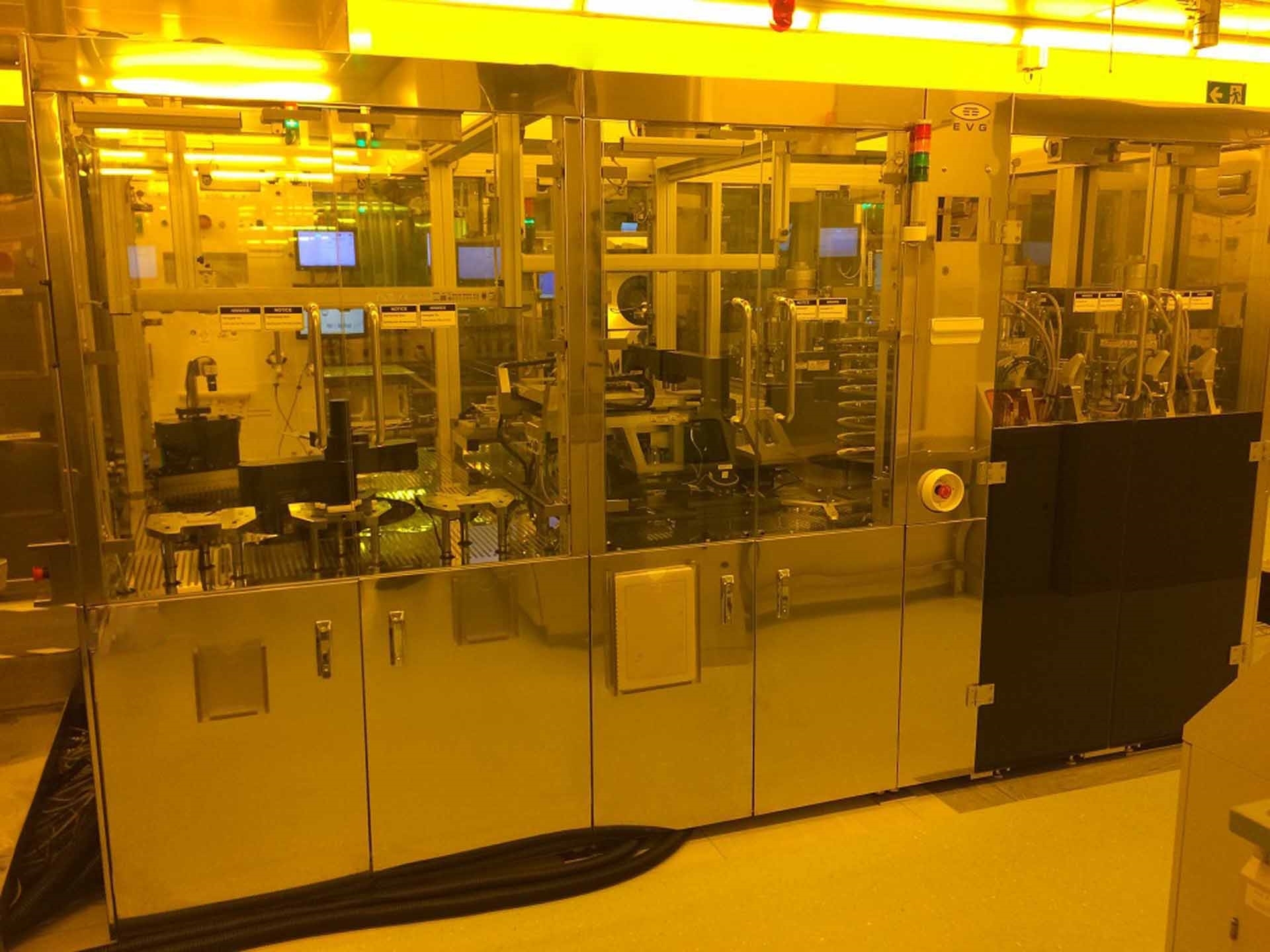

Used EVG / EV GROUP Gemini #9229293 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9229293

Wafer Size: 8"

Vintage: 2013

Automated wafer bonding system, 8"

Substrate handling module:

Between alignment stage and load cassette

Loading / Unloading: 4-Axis industrial robot

With external optical prealigner

Wafer handling:

End effector for robot unit

With vacuum from bottom side

Bond chuck handling module:

Between alignment station and bond chamber

Automated operation of up to (4) bond modules

Unclamp station with handshake to linear transfer station

Cassette station:

Present sensor

Empty sensor

Graphical user interface for manual and fully automated operation

Independent sequence

Monitoring

Data storage

Wafer ID reader:

SEMI T1 (Barcode)

SEMI M12, SEMI M13 (Both alphanumeric)

SEMI T7 (Data matrix code)

High resolution alignment stage with DC servomotors in X, Y and Θ

Top and bottom wafer chuck with position measurement system

Fully motorized split field microscope for double side viewing

High resolution digital CCD cameras

Integrated magnification unit: 1x - 3x

Alignment with split field microscope

Objective: 5x

Loading chuck, 4"-6"

Bond module:

Universal bond chamber with top and bottom side heaters

Flag pulling mechanism

Up to 550°C and 3.5 kN

Atmospheric capabilities down to 1 x 10^-3 mbar (7.5 x 10^-4 Torr)

Pressure: 3 bar abs.

Connections for evacuation, purge and vent

Independent temperature controllers for top and bottom side of each chamber

Electronic pressure regulator for controlled contact force

Pneumatic wafer bow pin:

For most accurate alignment of separated wafers

Spring-loaded pin in bond chamber

Rapid cooling for top and bottom side heater:

For symmetric top / Bottom side cooling at identical

Forced water cooling

Silent operation

Programmable cooling rate

Increased piston force: Up to 10 kN (2250 lbf)

Resolution: 3 N steps

Pressure disk, 4"-6"

Universal bond chuck, 4"-6"

For anodic, thermo compresion and eutetic bonding process

Bond chuck with mechanical wafer direct clamping

Bond chuck out of titanium

Vacuum equipment with bypass system:

Pump time: < 2min from 1000 to 1 x 10^-3 mbar

Gas backfill time: < 10sec from high vacuum to 1 bar

Purge connections for process gas

Pump down time: From ambient to 2 mbar abs. pressure < 60s

Vacuum controller: 1 - 1000 mbar

Resolution: 1 mbar

Accuracy +/-0, 5% / +/-3 mbar

With piezo gauge and control valve

Minimum controllable pressure: 1mbar abs

Hardware:

SEMI-E4:

Semi Equipment Communication Standard (SECS-1)

Message transfer: Hardware interface RS232

SEMI E37:

High speed Secs Message Service (HSMS)

Generic services

Hardware interface: Ethernet TCP/IP

Tooling with system:

Bond chucks with graphite: 9 x 6”

Graphite pressure disks: 4 x 6”

Objective:

Bottom and top alignment

With standard 5x objectives with red LED

Second N2 line is installed in each module

Controlled with needle and bypass valves

Includes:

Chiller

(4) Vacuum pumps

(4) Turbo pumps are installed in chambers

Operating system: MS-Windows

2013 vintage.

EVG / EV GROUP Gemini Bonder is a production-ready, high-throughput, automated wafer bonding tool with precise and repeatable bonding results. This tool provides a robust platform for adhesive bonding thin wafers, and wafer-level packaging for sub-millimeter tolerances. EVG Gemini Bonder is designed to bring maximum throughput, precision and repeatability to the wafer bonding process. Its advanced features include control over temperature, pressure, and time. This ensures a robust bond that is durable and reliable. Additionally, EV GROUP Gemini Bonder features intuitive user interface, automation, and repeatable processes, with adjustable parameters to ensure the highest yield. With a small footprint and a low vacuum head, Gemini Bonder is an ideal solution for both small and large production processes. The system includes an auto load/unload module for wafers up to 8" diameter. The load/unload module includes precision nozzles to accurately and repeatably deliver bond fluids. It also has a four-head bonding station, which can accommodate up to four different bonding processes. The station is fully compatible with UV adhesive and gel systems. It also includes automated alignment, along with programmable pressure and temperature ramps. EVG / EV GROUP Gemini Bonder also offers total process control and real-time feedback, with the ability to save and load previously run processes for repeatability. It utilizes online menus to select, monitor, and control all of the process functions. EVG Gemini Bonder also features an easy-to-use GUI (graphical user interface) that allows users to monitor, tune, and adjust process parameters in real-time. EV GROUP Gemini Bonder is compatible with various packages and substrate materials, and it is highly configurable with a wide range of adjustable parameters. It is easy to integrate with other systems, and it is low noise, which makes it suitable for various cleanroom environments. Additionally, the system is compatible with a selection of optional hardware modules, which allow for further downstream application you. Examples include laser cutting, lithography, vision-based gating, and more. This makes Gemini Bonder an attractive choice for many wafer bonding applications.

There are no reviews yet