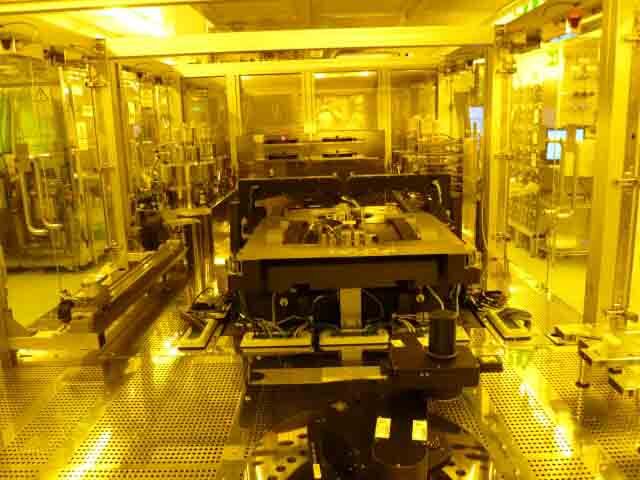

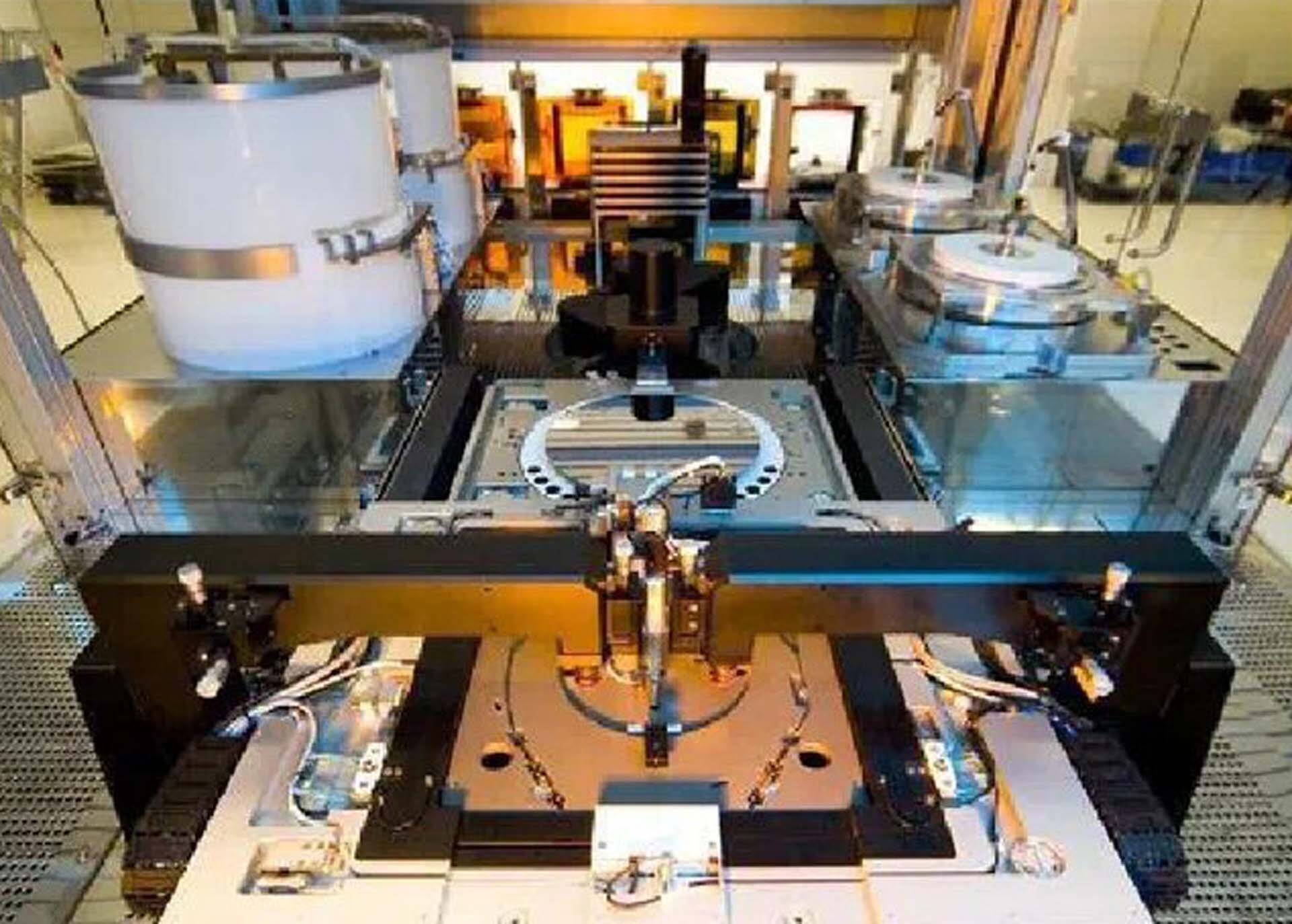

Used EVG / EV GROUP Gemini #9390777 for sale

URL successfully copied!

Tap to zoom

ID: 9390777

Wafer Size: 12"

Fusion bonders, 12"

Automatic optical alignment function

C Bonding device

Compliant with SEMI Standard

FOUP, 8"

(2) Thickness of each board: 0.5 ~ 1 mm

Total thickness: Up to 2 mm

Processing power

SmartView NT

Cleaning station

Plasma chamber (Optimizing parameter)

(12) Sets of wafers can be bonded together per hour

(2) Cleaning stations

Optical pre-aligner

Wafer ID Reader

Control frame

Mini-environment

Roughing pump

Transfer robot

(3) TDK FOUP Load ports

Wafer transfer robot

User interface:

Keyboard

Trackball

Joystick

TFT Flat screen, 17".

EVG / EV GROUP Gemini is a state-of-the-art wafer bonder designed for use in the semiconductor and microelectronics industry. It is a semi-automated equipment that offers superior accuracy, repeatability, and control for the direct bonding of various types of substrates. The bonder features integrated vision and inspection technology, allowing for precision alignment and alignment accuracy up to 0.1 μm. The bonder can accommodate four-axis movement to enable precise and repeatable process capabilities across a range of substrates and application requirements. In addition, it offers a variable bond force ranging from 0.2 N to 10 N, providing ultimate control for the precision joining of different materials. The fast processing speed of up to 400 mm/s ensures efficient operation as well as high throughput. The system has advanced process monitoring capabilities with integrated vision and inspection tools for end-of-line inspection. It provides customizable statistical process control (SPC) for detailed comparison with pre-defined parameters and tolerances to ensure precise process control and end-product performance. EVG Gemini Bonders are designed with a modular format, providing both flexibility and scalability to accommodate changing process requirements. Up to four separate bonding platforms are available for maximum productivity and throughput, and all wafer head types can be used across the modules. The unit is readily integrated into automated bonding environments, in order to create a fully automated process and minimize manual operations. For quality control and repeatability across processes, the machine offers a number of advanced features, such as signature recognition for end-of-line control. It also includes an enclosed, automated cleaning station for bonding head plates, eliminating the need for manual cleaning and reducing the possibility for human error. EV GROUP Gemini Bonders offer an easy-to-use user interface that allows for quick activation of process recipes and user profile setup. The tool is compatible with most production trackfiles, allowing for rapid development time and installation. As a result of its high functionality and versatility, Gemini Bonders can be utilized for a wide range of applications. It is a reliable, accurate solution for direct wafer bonding of dielectric and metallic materials, as well as a range of optical elements. This asset can also be used for flip-chip and wafer-level packaging, MEMS and other micro-assembly processes, and various RF and antenna applications. In conclusion, EVG / EV GROUP Gemini Bonders offer precision, repeatability, and process control for a wide range of semiconductor and microelectronics applications. Its powerful features, flexibility in configurations, and robust process monitoring capabilities make it an ideal choice for all bonding types and production needs.

There are no reviews yet