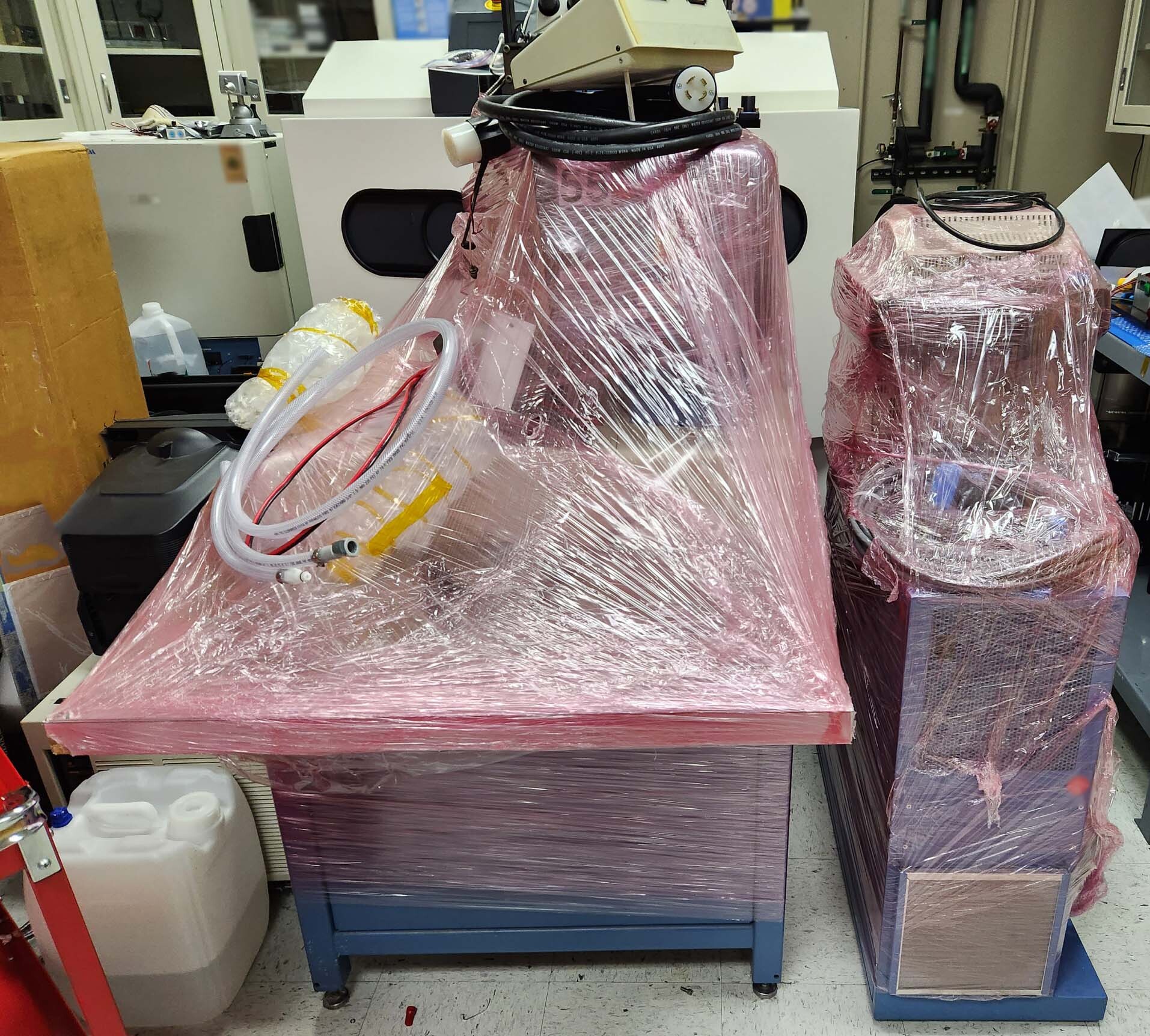

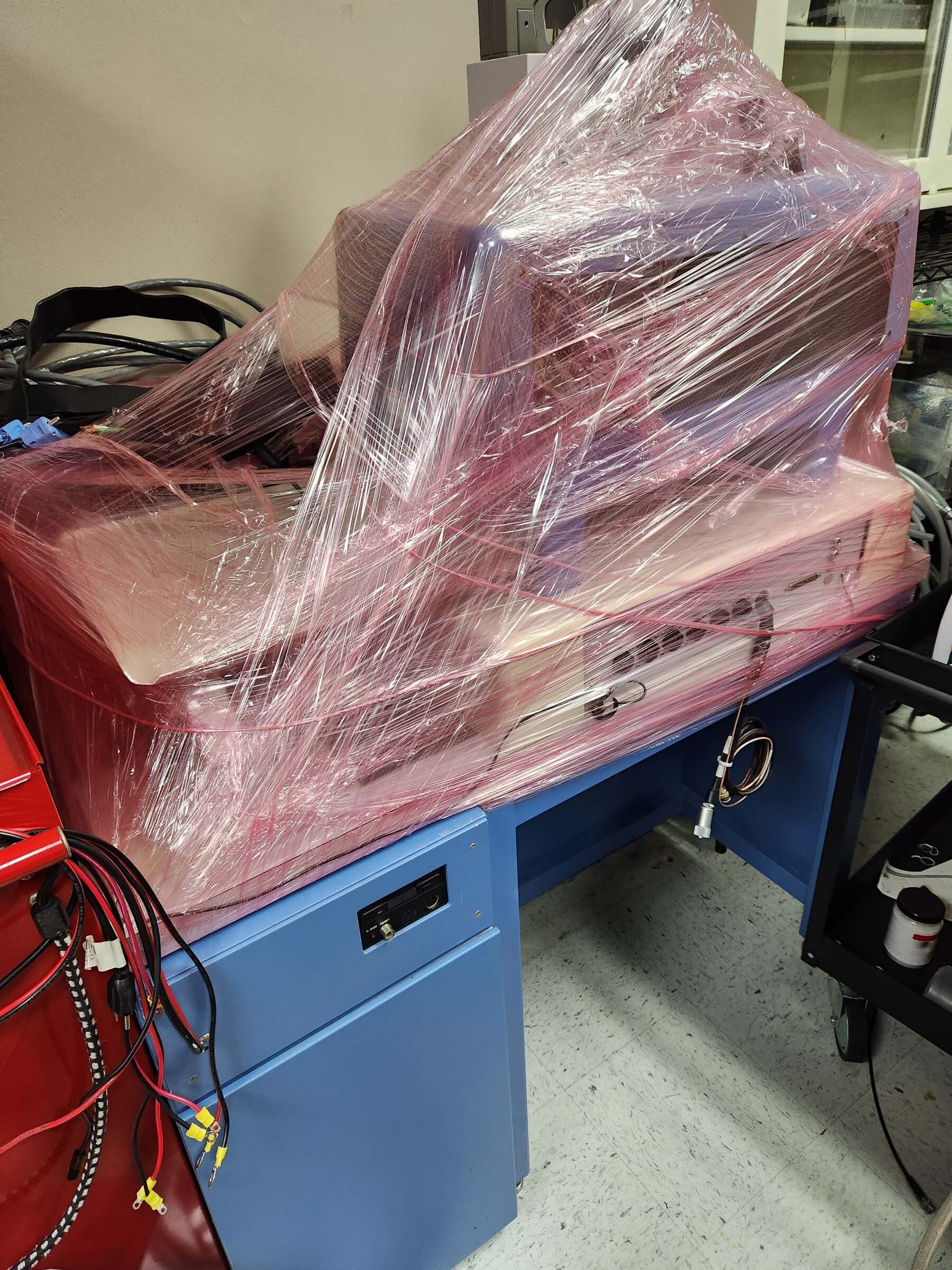

Used HUGHES / PALOMAR 2470-V #293662301 for sale

URL successfully copied!

Tap to zoom

HUGHES / PALOMAR 2470-V is an automated bonding equipment designed to manufacture semiconductors, magnetic heads, and other similar micro-electronic components. This system uses a combination of mechanical and thermal energy to form long-term bonds between dissimilar materials, such as dissimilar metals or between semiconductor materials and other metals. The unit also features a robotic arm, which can be programmed to move in two, three, or four directions and is capable of carrying components to and from the bonding process. The heating process used by HUGHES 2470V is a forced convection method, allowing for uniform heat to be evenly distributed throughout the area of work, resulting in uniform bonding. PALOMAR 2470 V is comprised of a base frame and a work area, which is surrounded by a nitrogen purge hood. This hood is programmed to provide a nitrogen atmosphere to the work area, ensuring that oxidation is minimized during the bonding process. The machine includes a base frame mounted two-axis robotic arm. This arm can transport parts from the load station, where they are positioned for the start of the process, to the discharge station, where they are delivered at the end of the process. Additionally, the base frame mount arm carries the bonding tool head to the designated locations on the wafer where bonds will be formed. The heating process is done through the use of a hot bar bonder, which is a platform that combines two different materials into a single part. Hot bar bonding raises the temperature of the two materials, allowing the bond to occur quickly and with minimal thermal degradation. The use of a dual heater tool allows for even heat distribution across the entire area of work, resulting in evenly formed bonds. The hot bar can also be positioned horizontally, allowing for better access to the underside of the parts that need to be bonded. PALOMAR 2470V also features a temperature controller, which is used to measure the temperature of the heater. This allows the user to control the temperature and ensure that the bonds being formed are of the highest quality. Additionally, HUGHES 2470-V features a vision asset, which monitors the bonding process and detects any possible misalignment of parts. Overall, HUGHES / PALOMAR 2470 V is a unique and reliable model that simplifies the process of bonding dissimilar components used in the manufacture of micro-electronic components. The equipment's features - such as the combination of the robotic arm, nitrogen purge hood, dual heater system, and vision unit - work together to ensure high-quality bond formation.

There are no reviews yet