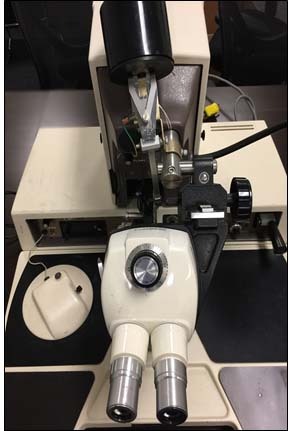

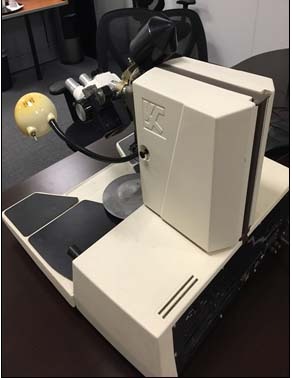

Used K&S 4124 #9176277 for sale

URL successfully copied!

Tap to zoom

K&S 4124 is a metal bonder with a state-of-the-art design. It is a single-operator system that was built from the ground up to deliver superior adherence between metal sheets and overlapping edges of pieces. It has a weld time capacity between 0.2 and 1.2 seconds and a welding pressure range of 0-50 kgf/cm2. 4124 bonder features a high output triangular spot welder with two power levels. The output welding power can be adjusted between low and high power settings. It provides an even contact pressure and consistent welding power over the entire welding area. Additionally, the welding tip is adjustable, so the operator can customize the size, shape, and coverage area of the welding spots. K&S 4124 is designed for use in both automatic and manual welding systems. It features a welding sleeve that ensures correct alignment during the welding process with an elliptical welding gap. The adjustable bead design enables the operator to customize the welding bead and spot shape according to the welding requirements. It is equipped with a vacuumed, double-gasket seal that provides a reliable weld and maximum protection against outside contamination and moisture. The bonder includes a positioner for quick setup and precise positioning of the parts during welding. Additionally, the easy-to-use digital display and automatic temperature control unit ensures the highest precision and optimal weld results. 4124 bonder is designed for safe operation and low maintenance. It has built-in safety features including, an electronic fusion monitor, self-protection from welding currents, and overload protection. The splatters traps in the connection head eliminates splashing of molten metal as well. K&S 4124 bonder is made of durable material and it is capable of producing high-quality welds for a variety of materials with different thicknesses. It is suitable for carbon steel, aluminum, galvanized steel and stainless steel materials, making it a versatile choice. Additionally, it is compatible with a wide range of welding parameters and can be used in environments where accurate welding is a must.

There are no reviews yet