Used K&S 8020 #9099064 for sale

URL successfully copied!

Tap to zoom

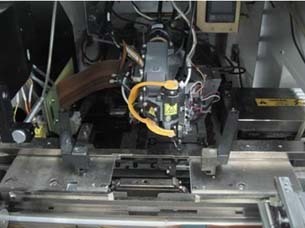

K&S 8020 is an industrial, large-scale, fully-automatic bonder equipment manufactured by Kisters, designed for production in medium to large industrial production environments. The system is part of the company's "Miracle Unit" range, and offers a cost-effective, efficient and reliable solution for production rates up to 2,000 products per hour. The machine comes equipped with multiple components that help it to provide a comprehensive bonding solution. The components include an automated bonding tool, an adjustable table with double drive asset, a clamping/clamping model for fastening different products, an adjustable platform to control process parameters, and an integrated control equipment for precise processes. The system is also designed with an integrated waste recycling unit, to ensure the highest level of efficiency. The main part of the machine is the automated bonding tool, which is capable of providing a wide range of bonding figures, including surface, line and even point-to-point connections. The asset uses AC, DC and pulse circuits to create bonds between wires, boards, connectors, fibers and other components. The model uses air assisted flow channels to feed material to the bonding tools, and to ensure that each connection is properly made. The equipment can also be used to bond a variety of non-conductive material, such as metal, plastic or ceramic. The adjustable table allows for a variety of adjustments to be made, including the level of pressure, the speed of the process, and the number of products to be bonded. The double drive system ensures that the process runs smoothly and efficiently, and that it is capable of providing a broad range of bonding patterns. The clamping/clamping unit makes it possible to quickly move and adjust different products, without wasting time setting up the machine again. The adjustable platform, which is built into 8020, allows for quick and easy customization of the tool's process parameters. This platform allows for the user to control the speed, motion and power of the asset, and ensures that the quality and accuracy of the bonding process is kept in check. The integrated control model also allows for precise fine tuning and adjustments to be made to the equipment, ensuring that quality control is maintained throughout the process. The integrated waste recycling system helps to minimize material waste, and further reduce the unit's environmental impact. Overall, K&S 8020 is an efficient and reliable high-performance bonder machine that is well-suited to medium to large industrial production environments. The tool offers easy process customization, and high levels of accuracy and quality control. With its integrated recycling asset, the model is also highly efficient and highly cost effective.

There are no reviews yet