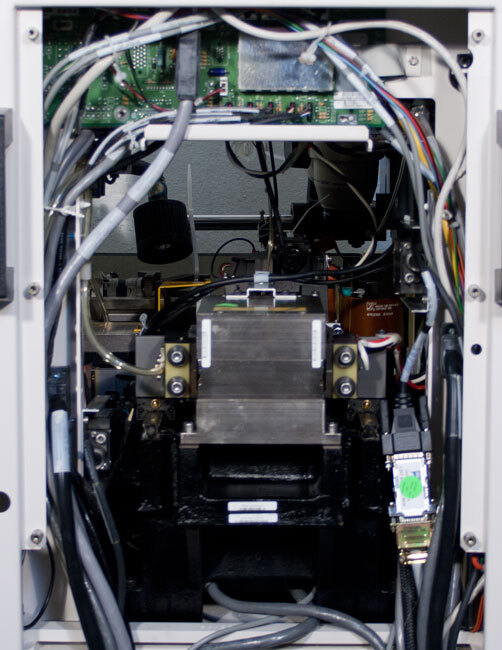

Used K&S 8028SG #9011278 for sale

URL successfully copied!

Tap to zoom

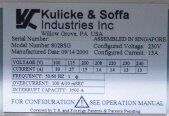

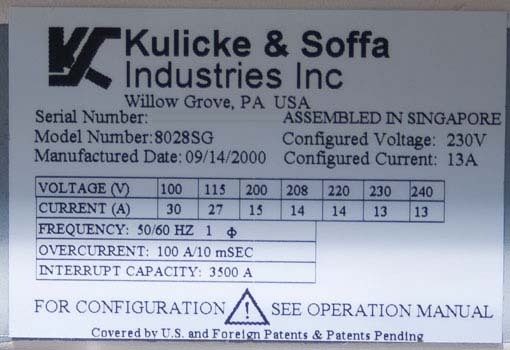

ID: 9011278

Vintage: 2000

Fine pitch wire ball bonders

Power Requirements: 230 V, 13 A, 50/60 Hz, Single Phase

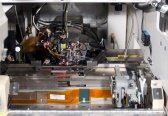

Major Component System Inventory:

Olympus SZ30 Microscope with 110AL0.62X WD160 (No Eyepieces!)

MS Amp - 8002-4014: N08002-4014-000-01

Dual HS 2A/.8A - 8002-4104: N08002-4014-000-01

Dual HS 2A/.8A - 8002-4104: N08002-4014-000-01

Dual HS 2A/2A - 8002-4103: N08002-4103-000-005

X/Y Amp - 8001-4105

X/Y Amp - 8001-4105

Dual HS 2A/2A - 8002-4103: N08002-4103-000-00

Clamp Drvr - 8001-4102: N08001-4102-000-02

Sol. Drvr - 8001-4020: N08001-4020-000-03

Z Amp - 8001-4145: N08001-4145-000-03

Dual HS 2A/2A - 8002-4103: N08002-4103-000-00

Dual HS 2A/2A - 8002-4103: N08002-4103-000-00

Comm Port (With GMS Board) - 8002-4187: N08002-4187-000-00

ESI AIS-640/266

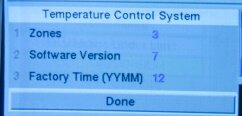

Temp Cont - 8002-4017

USG - 8001-4081: N08001-4081-000-08

Servo CPU - 8001-4143: N08001-4143-000-06

Servo Preamp - 8001-4107: N08001-4107-000-06

Stepper - 8001-4073: N08001-4073-000-06

Sensor - 8001-4072: N08001-4072-000-05

I/O - 8001-4058: N08001-4058-000-09

2000 vintage.

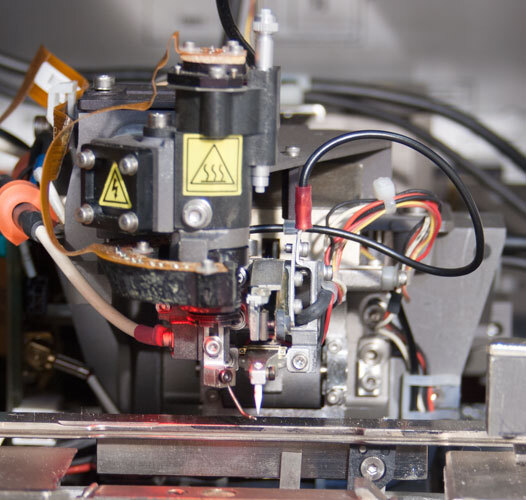

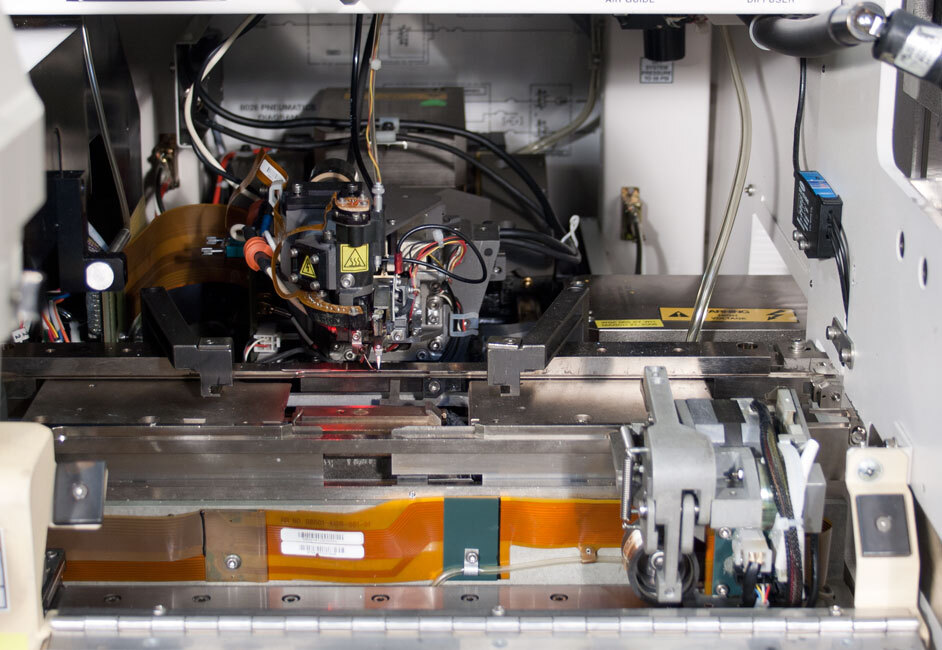

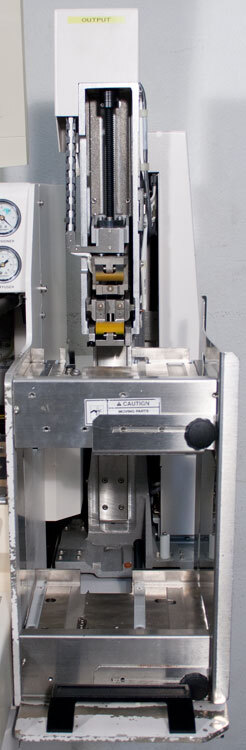

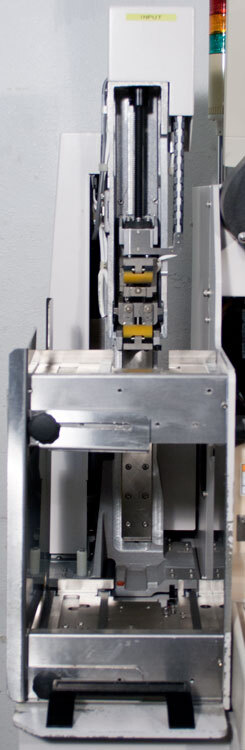

K&S 8028SG is a state-of-the-art, automated surface mount technology (SMT) bonder. This bonder is designed to automate the placement of components on circuit boards, and simultaneously enhance productivity and optimize product performance. K&S 8028 SG has a precision placement head and an 8-position rotary head, allowing the user to quickly and accurately place components onto the printed circuit board without manual intervention. The placement head can handle components of different sizes and shapes, and is compatible with both leaded and lead-free components. The placement process is fully programmable to allow for fast and precise placement of components. The versatile rotary head can handle all SMT components, allowing for efficient pick-and-place operations. In addition to its advanced placement capabilities, 8028SG also offers a wide range of thermal and vacuum bonding options, allowing for enhanced reliability in the bonding process. Vacuum bonding is recommended for larger chip components and components with greater thickness. Thermal bonding, conversely, is recommended for small chip components and components with lower thickness. Both the vacuum and thermal bonding processes are fully automated and programmable to meet customer specifications. 8028 SG also offers an integrated control equipment with sophisticated algorithms for maximum efficiency. The control system enables precise speed and power controls, as well as a comprehensive overview of the bonder's performance. These advanced control functions help ensure product quality and reliability by reducing the risk of component misplacement. In addition, the control unit helps designers and operators determine the most effective combination of process parameters for optimized product performance. K&S 8028SG is a reliable, high-performance automated bonder for complex SMT applications. With its robust design and comprehensive control machine, this bonder is an ideal choice for manufacturers seeking to automate their production process with little to no manual intervention.

There are no reviews yet