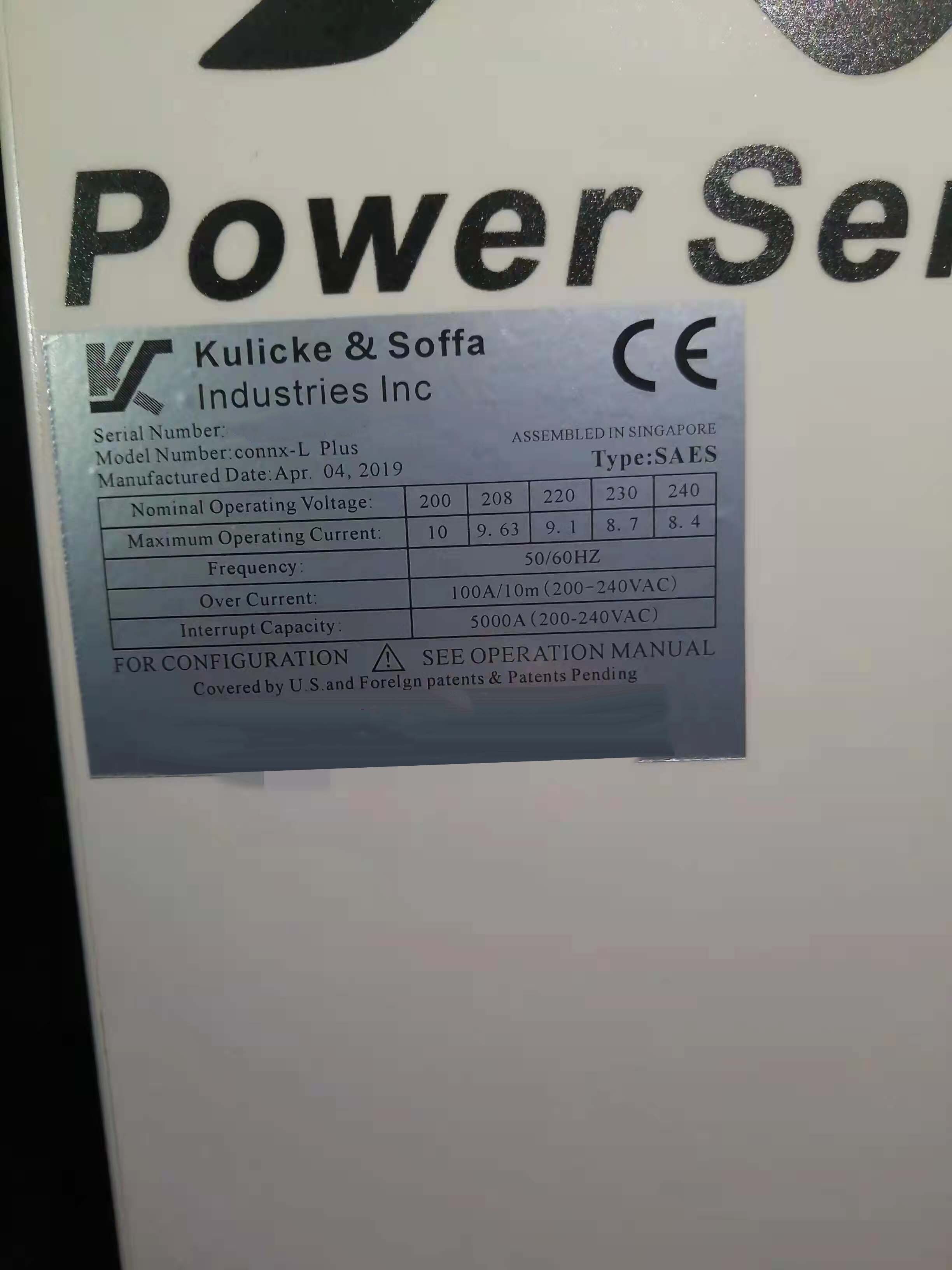

Used K&S ConnX-L Plus #293595580 for sale

URL successfully copied!

Tap to zoom

K&S ConnX-L Plus is a revolutionary one-step bonding process for the fabrication of microelectronic packages, components, and other related products. This advanced process uses ultra-pure solder paste that is precisely dispensed, resulting in a quality bond. Utilizing this dual-cure process reduces material costs and speeds up production times, making it a valuable tool for the fabrication of microelectronics. ConnX-L Plus bonder utilizes a combination of an automatic nozzle dispenser and two-step curing process to accurately and consistently place small-scale amounts of solder paste onto the desired area. This ensures maximum accuracy in the final product, ensuring that all components are properly bonded together. Additionally, the bonding process is fast and efficient, allowing for fewer errors and greatly reduced production times. The bonder utilizes a special LED curing station for the second step of the bonding process. This LED curing is highly efficient and requires only a few seconds of exposure to achieve a quality bond. This efficient curing process is capable of bonding a variety of substrates, including ceramic, wafer, and chip package substrates. Additionally, the LED curing is capable of curing the solder paste instantaneously, which eliminates the need for special curing cycles. Additionally, the bonder includes a built-in monitoring system that monitors for temperature, humidity, and other environmental parameters. By detecting any sudden changes in these conditions, it can adjust the heating elements of the system to maintain accurate conditions. Additionally, K&S ConnX-L Plus also includes a comprehensive data logging system, allowing operators to keep track of the production results and optimize the parameters of the process. In conclusion, ConnX-L Plus is a powerful and efficient bonder that allows the production of microelectronic packages to be completed with greater accuracy and at a significantly reduced cost. By introducing a two-step curing process and robust environmental monitoring, it significantly reduces the chances of errors occurring and reduces production times, resulting in a higher quality final product.

There are no reviews yet