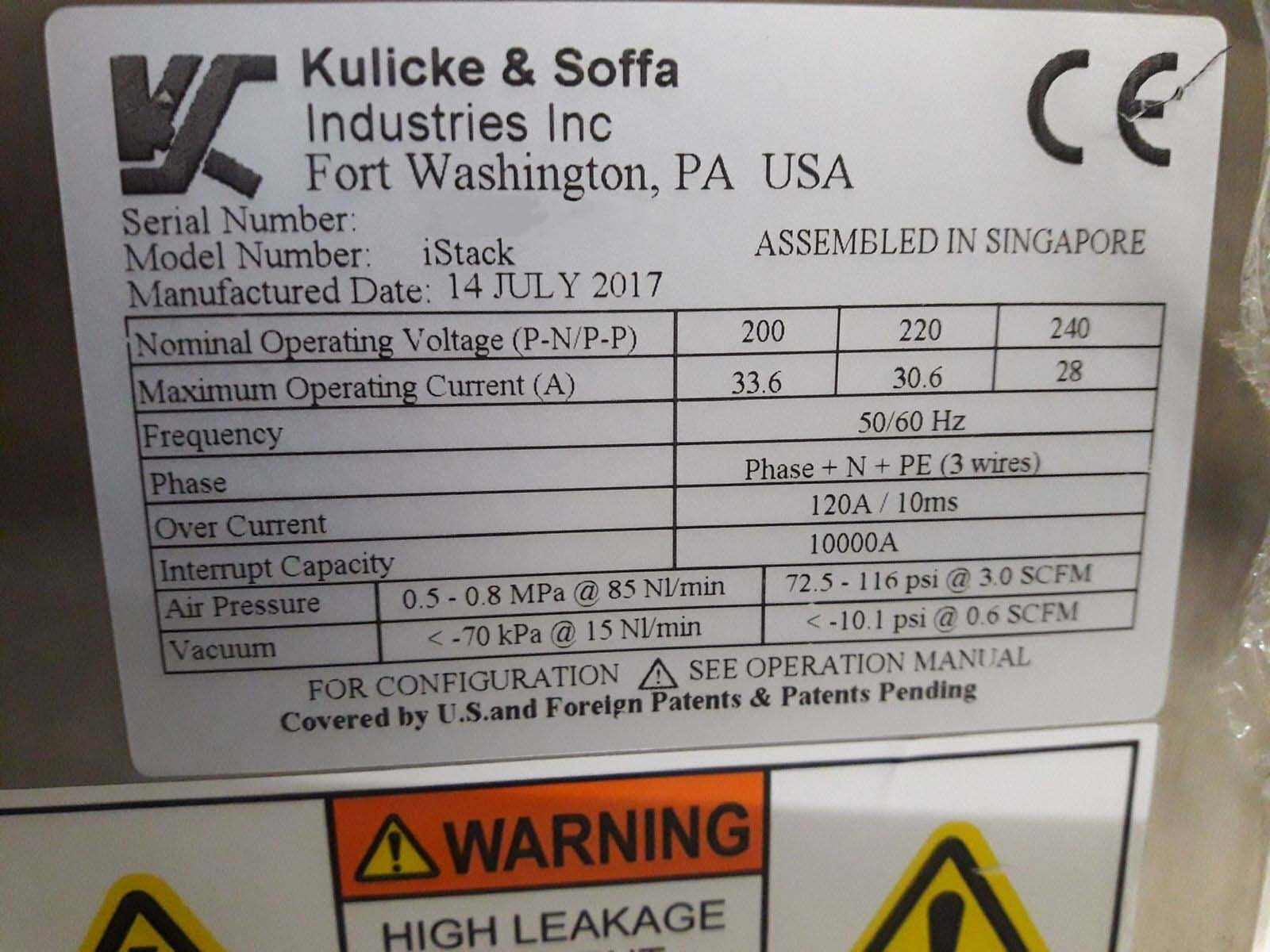

Used K&S iStack #293625555 for sale

URL successfully copied!

Tap to zoom

K&S iStack is a precision bonder designed for high reliability and repeatable accuracy. It is a 3-axis equipment which allows for accurate, reliable and repeatable bonding of small components and parts on even very small substrates. IStack's unique design and precision technology delivers a solution for high-volume production, cost-effective processes and fast process turnaround times. K&S iStack contains two parts, the base unit and the positioning system. The base unit provides a stable platform for the bonder. It contains several components, such as an integrated vision unit, an automated pick-and-place machine, and a precision spindle. The vision tool allows for rapid and accurate placement of parts using a camera and lighting asset. The automated pick-and-place model ensures accurate and repeatable placement of parts on the substrate. It can be programmed to place parts in different planes in order to ensure that the part is positioned correctly. The spindle is the part of the bonder that actually bonds the components onto the substrate. It contains a motor-powered, pistoned spindle that is used to apply pressure and move parts or pieces into their proper position. The other part of iStack is the positioning equipment. This includes a X-Y stage and an integrated microscope. The X-Y stage provides an adjustable base that is used to precisely position and align the parts that are to be bonded. The microscope provides a magnified view of the bond area, which allows the user to verify that the parts are properly bonded. K&S iStack has several advantages for high-volume production. It is designed for extremely fast process times and repeatable accuracy, making it ideal for high volume production operations. It is also relatively inexpensive, meaning that it can be used in most production scenarios. Furthermore, its precision technology provides accuracy, reliability and repeatable bonding results, even on small components and substrates. Finally, the system is easy to use and maintain, meaning that it will provide low cost of ownership and minimal downtime.

There are no reviews yet