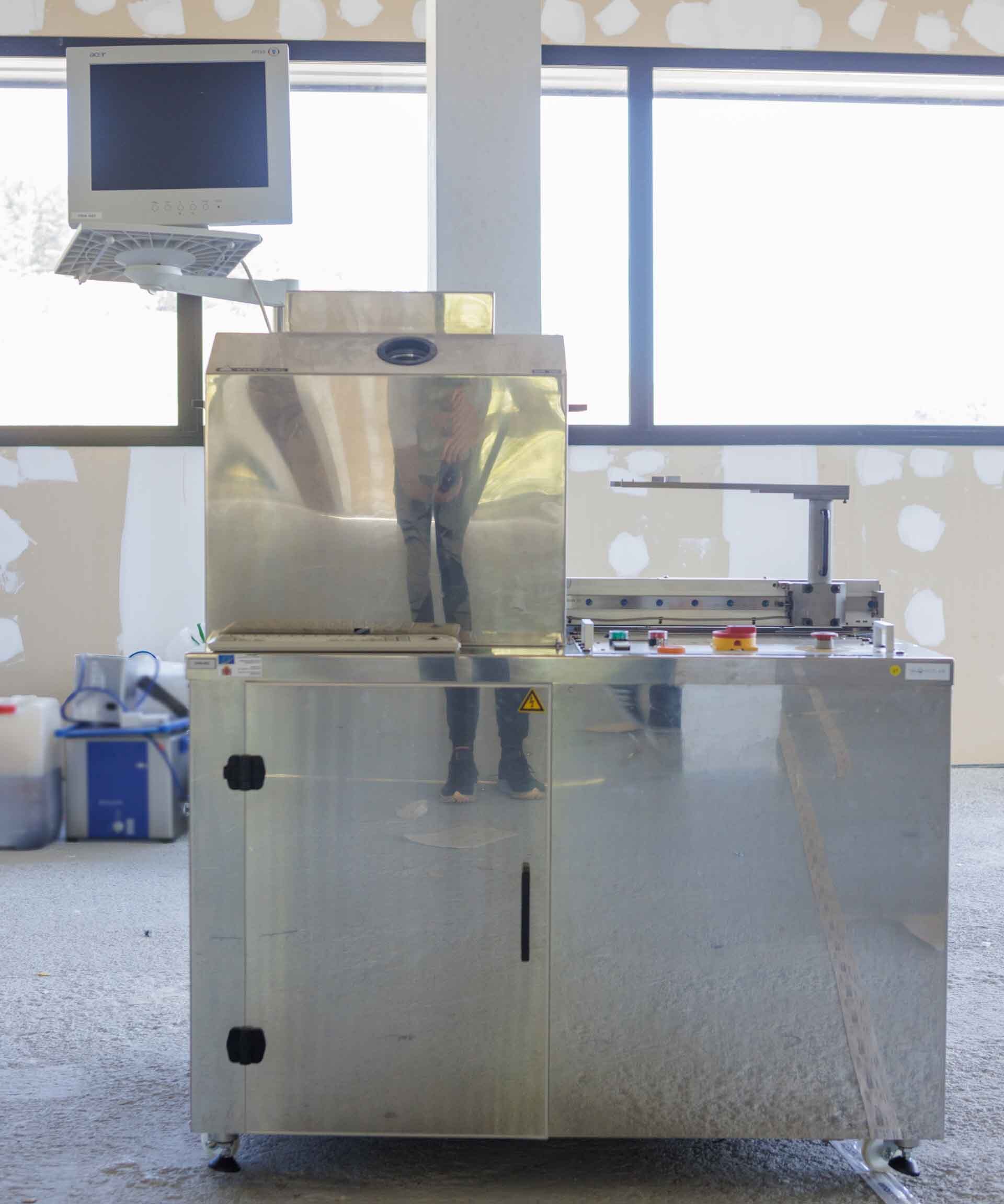

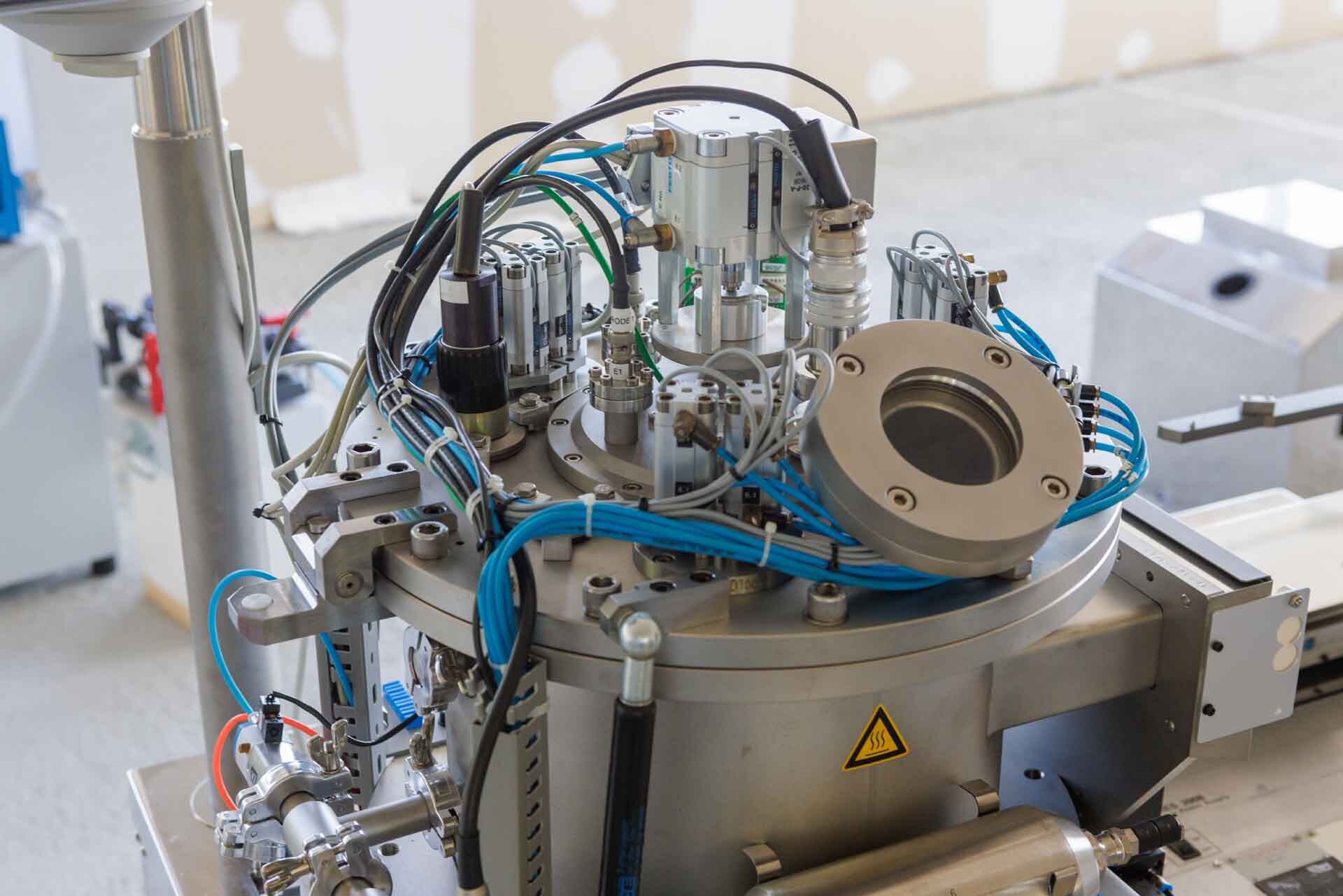

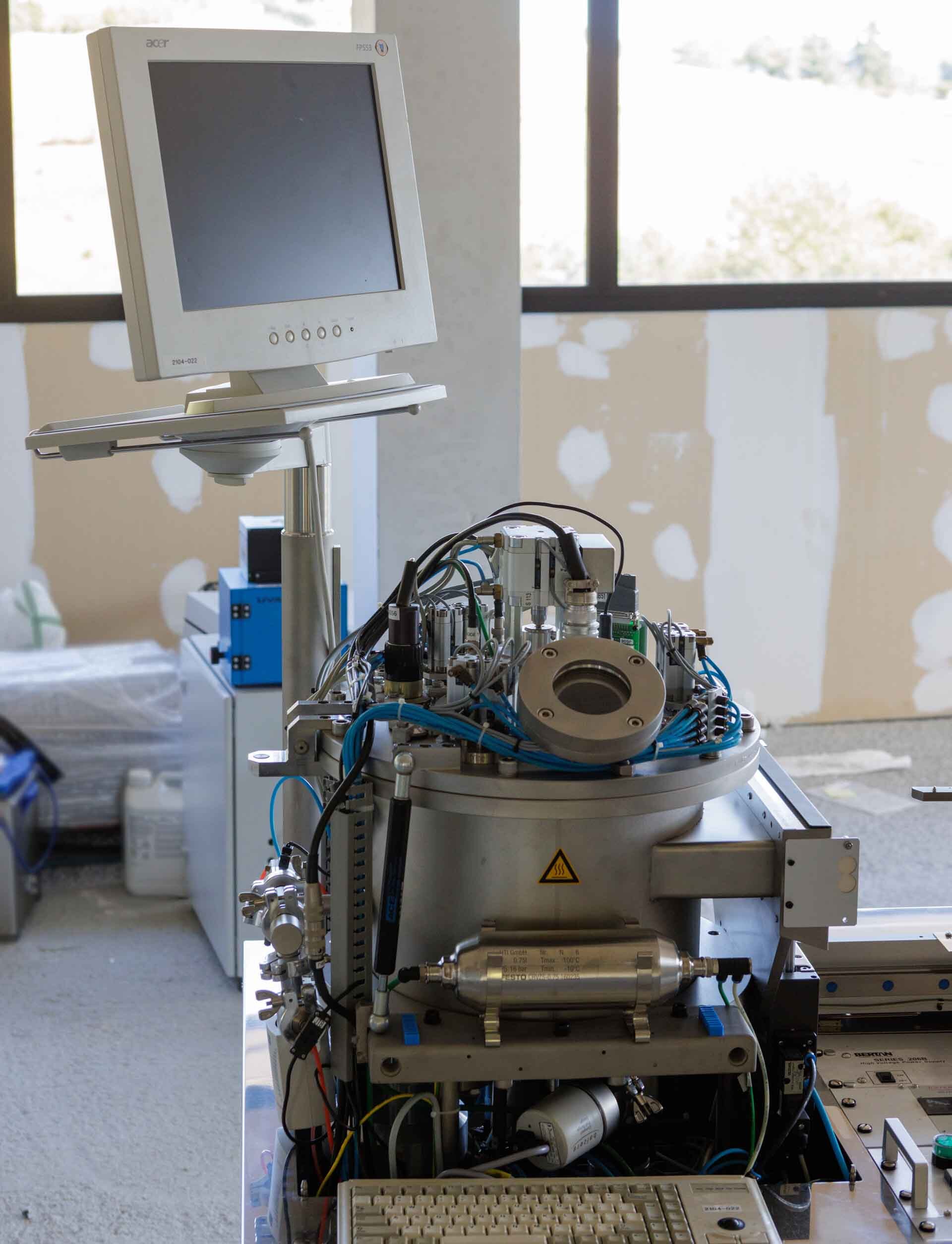

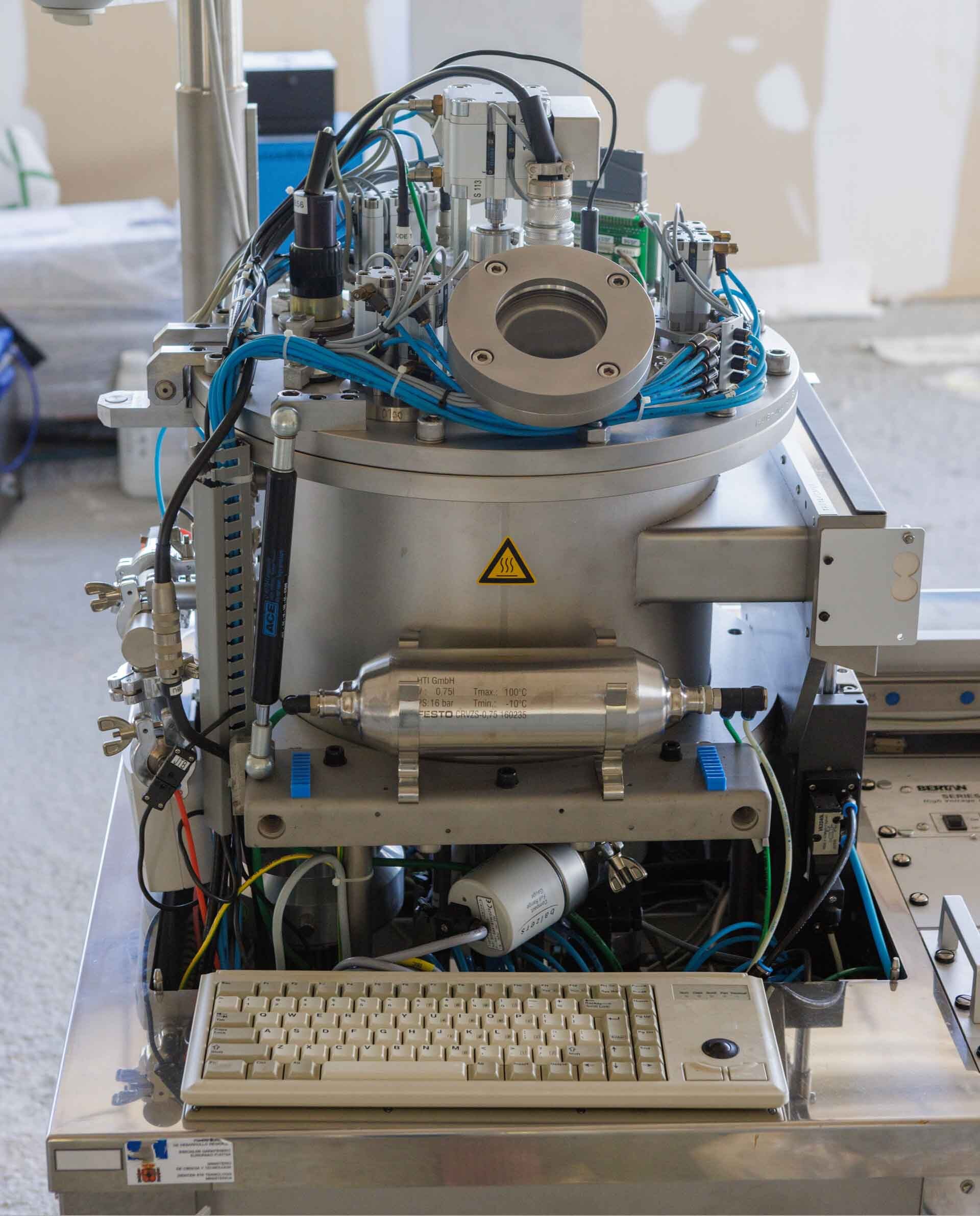

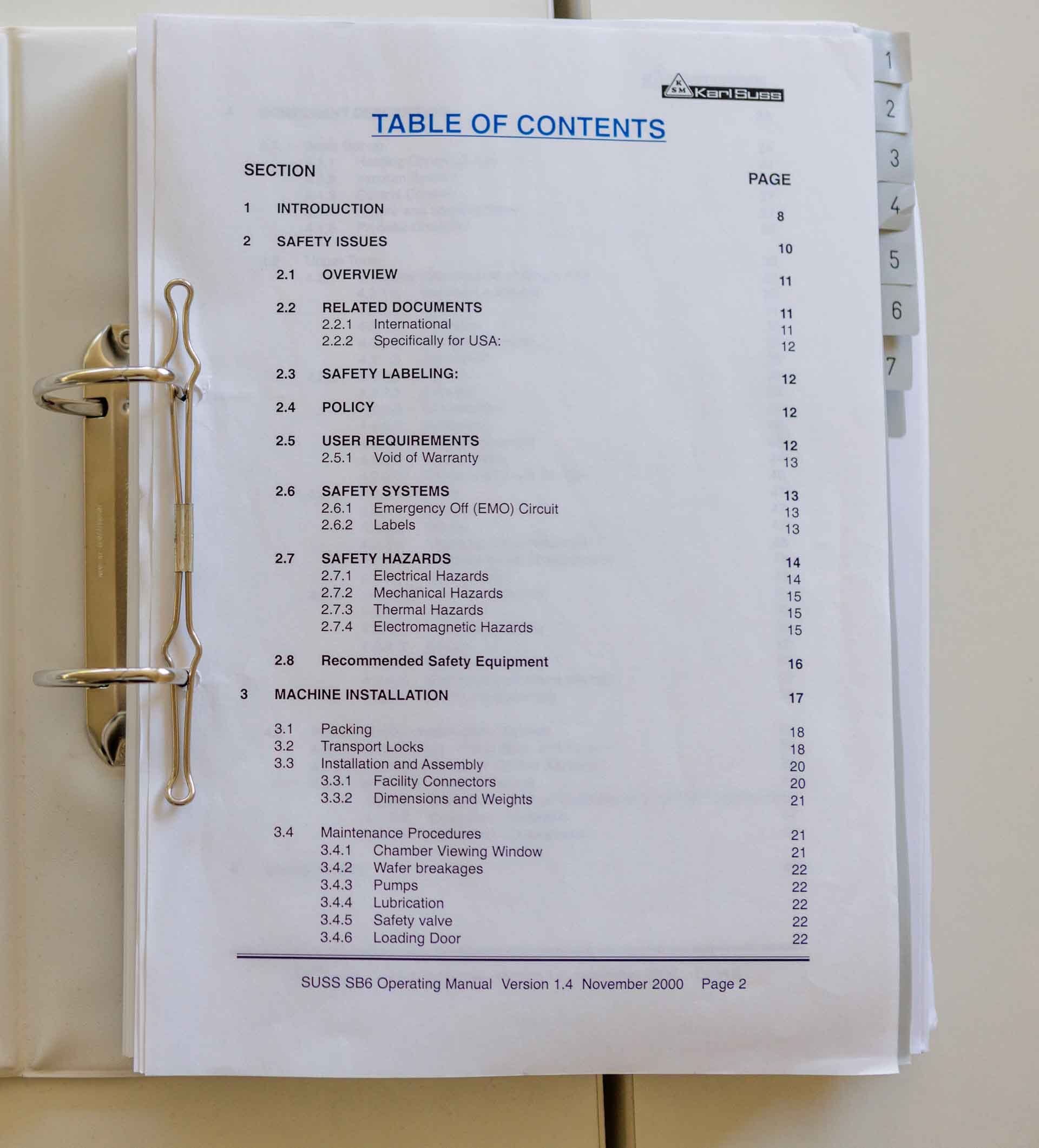

Used KARL SUSS / MICROTEC SB 6 #9039822 for sale

URL successfully copied!

Tap to zoom

ID: 9039822

Vintage: 2001

Substrate bonder, 4"

Can be configured up to 6"

Manual loading/unloading of previously aligned wafer in SUSS BA6 using the SUSS transport fixture

Software: automatic process data recording

Motorized Z axis

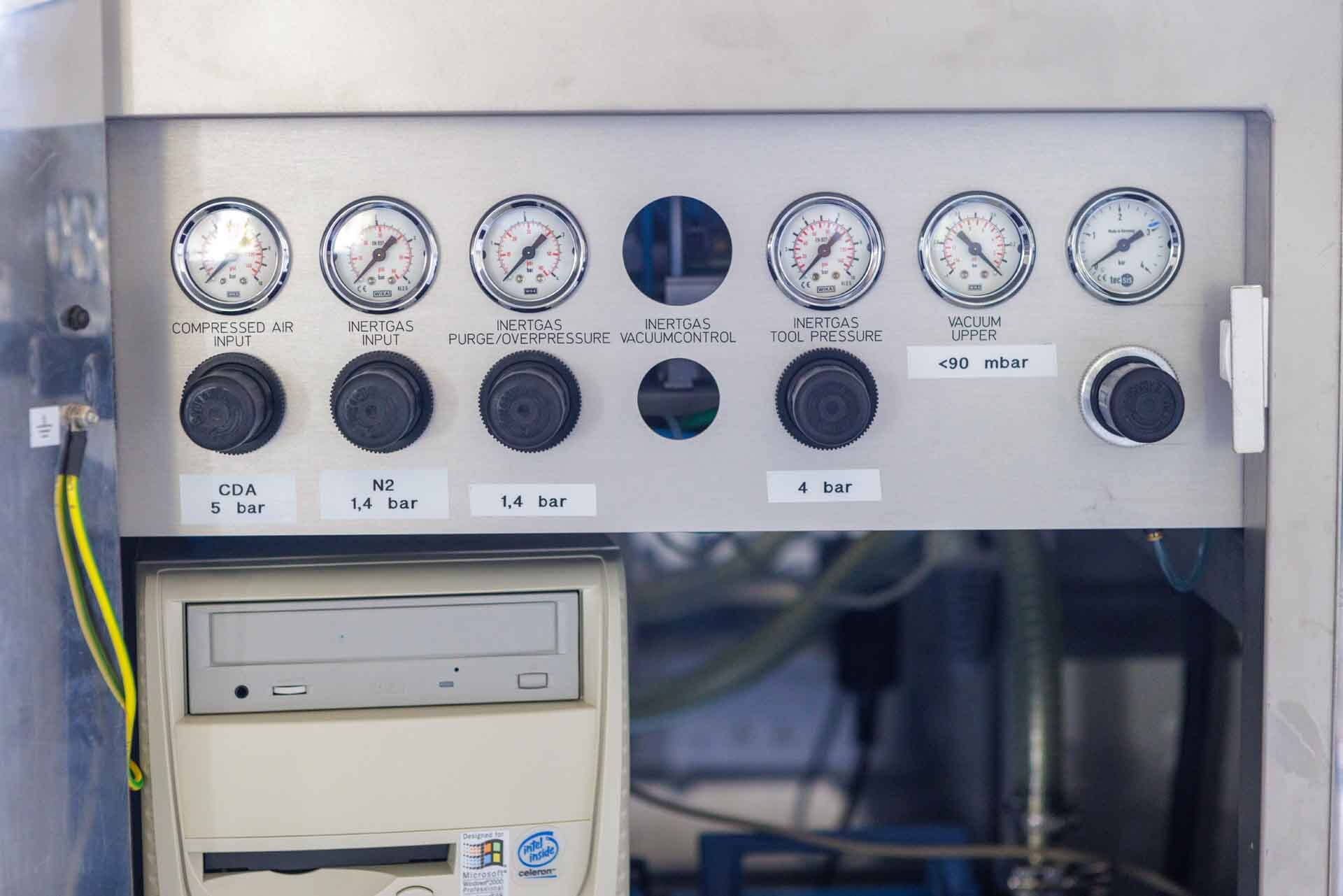

Chamber door with flange for automatic lid, class 1 cleanroom compatible

Overpressure in chamber to avoid contamination during load/unload

Adaptation for hot chuck A-150

Transport plate A-150 for loading sledge

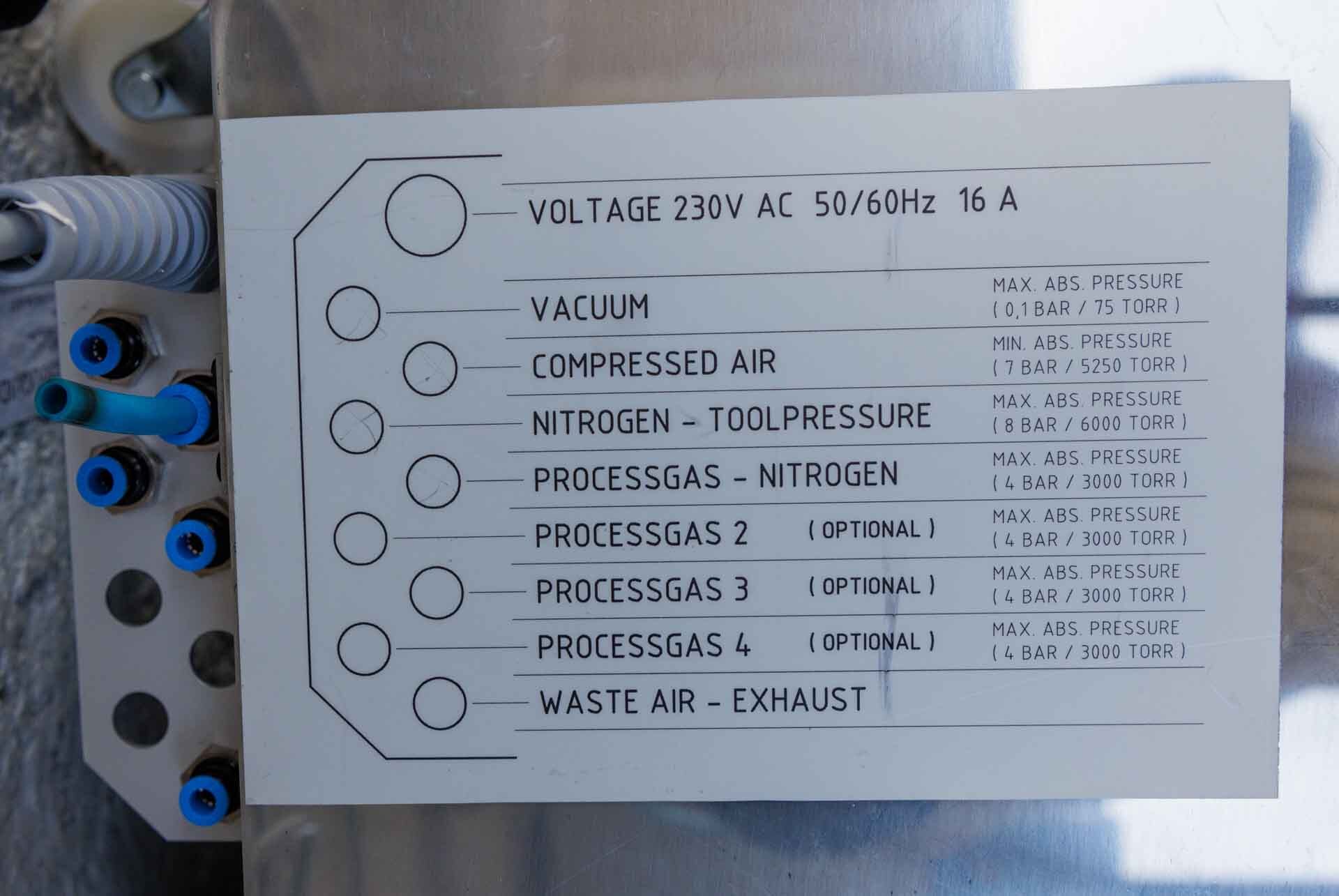

Vacuum:

Membrane pump: 30 l/min

Turbo molecular pump: Varian V250D

Pump time: <6 min from 1000 to 1x10-4 mbar in clean chamber

Purge time: <1 min from 0 to 1 bar

Hot chuck, SB6/W-150:

High vacuum bond chuck from <50 to 550 ºC with resistive heater and active air cooling

Hot chuck 150mm for fixture size A-150

Flatness 20 µm at 500 ºC

Temperature control +/- 5 deg, programmable temperature ramps

Temperature uniformity +/- 3%

Heating time 130-400 ºC 12 min

Cooling time 400-200 ºC 14 min.

Sandwich plate for hot chuck, SB6/W-100/A-150/90º

Universal bond tool, SB6II/P/E-AREA-C2/HEAT/W-150: anodic and thermo-compression-bonding of wafers W-100-150 and chips S-40-100, stack thickness 0,4mm-6mm

Spring loaded center bend pin: 20-50N, for keeping high alignment accuracy during heat-up

Heater: up to 500ºC

Pressure plate F. Uni tool, SB6/SST/W-100/A-150/P-8

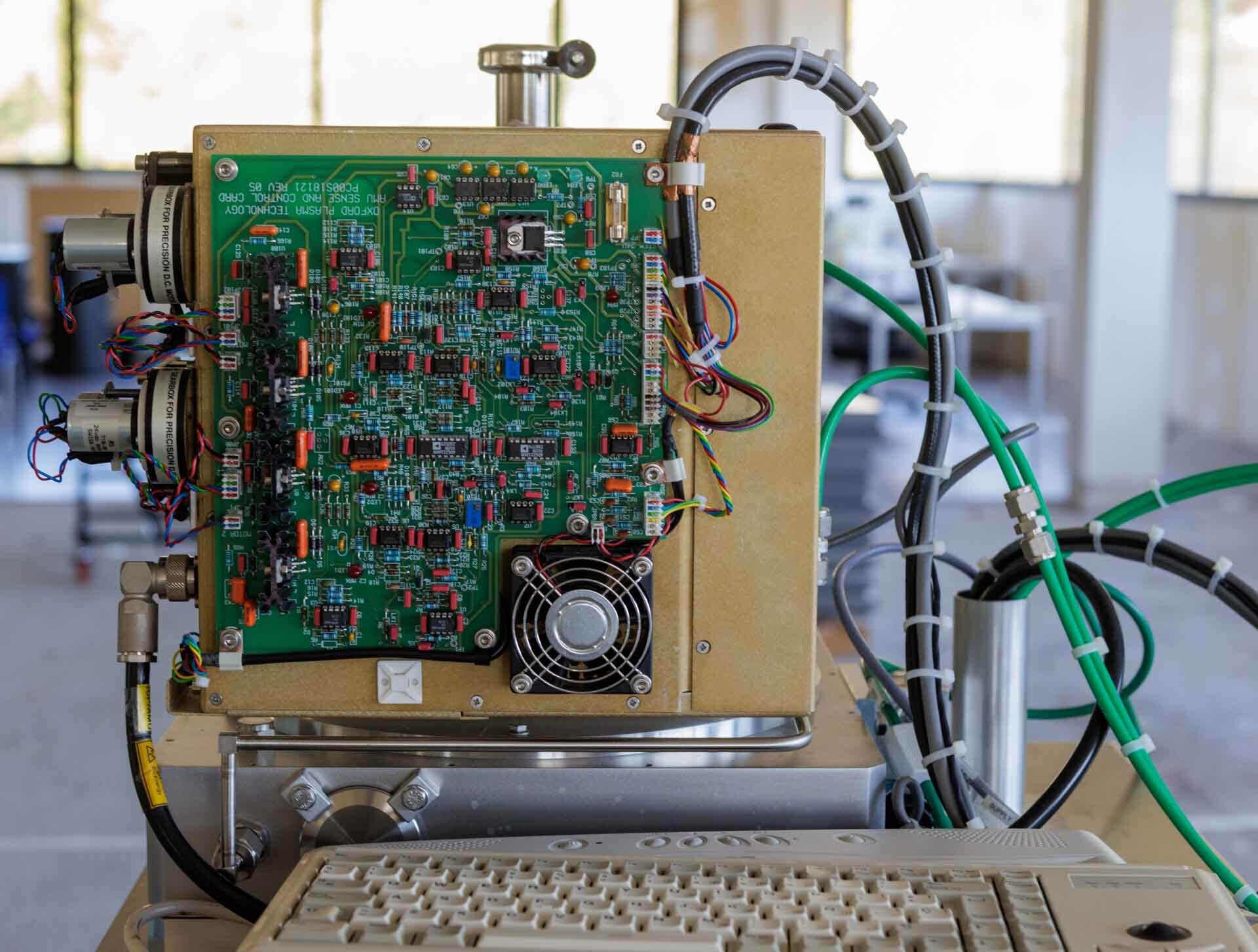

Anodic bond controller: 2KV/ 10 mA: programmable voltage, polarity, current limit

2001 vintage.

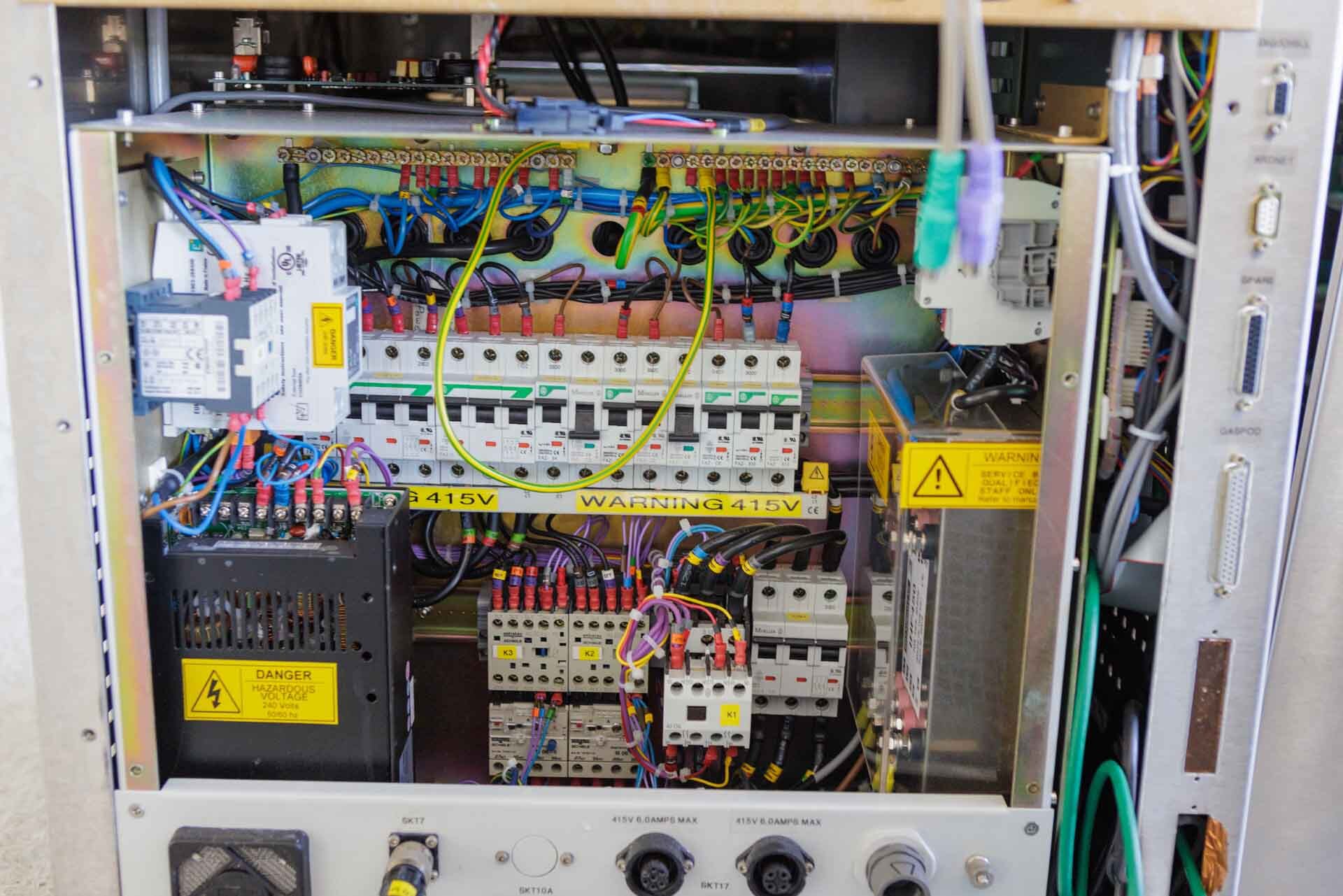

KARL SUSS / MICROTEC SB 6 is a computer-controlled semiconductor bonder that is used in a wide variety of scientific and industrial applications. This device is capable of producing unbeatable precision and accuracy in the bonding process. This makes it ideal for producing packages and assemblies with complex geometries and tight tolerances. MICROTEC SB 6 is powered by a state-of-the-art computer control equipment, which allows users to perform a number of precision bonding processes, including thermosonic bonding, thermocompression bonding, ultrasonic bonding, and more. The device is capable of producing pressure up to 30kPa and temperature up to 300°C for many types of bonds. The system also features an automatic positioning assembly station, as well as built-in pressure and temperature sensors that allow users to monitor the bonding process. KARL SUSS SB6 is designed with a large working surface area and provides a robust bonding and testing platform. The device is capable of handling components up to 9x9x9mm in size and up to 10-50g in weight. It also features a modular design which allows for user-configurable stationary and moving parts, enabling users to customize the machine for their particular applications. KARL SUSS / MICROTEC SB6 also features a user-friendly touch screen interface, allowing operators to easily set parameters, check status, and access different recipes. The device is capable of storing up to 20 different recipes, making it ideal for repeatable processes. MICROTEC SB6 is also equipped with an integrated vision unit, allowing operators to quickly inspect and analyze each bond. Overall, SB 6 is a precise, user-friendly device that offers an impressive range of features and capabilities. This device is ideal for producing packages and assemblies with complex geometries and tight tolerances that require precise control. With its state-of-the-art computer control machine, modular design and integrated vision tool, this device is sure to meet even the most demanding applications.

There are no reviews yet