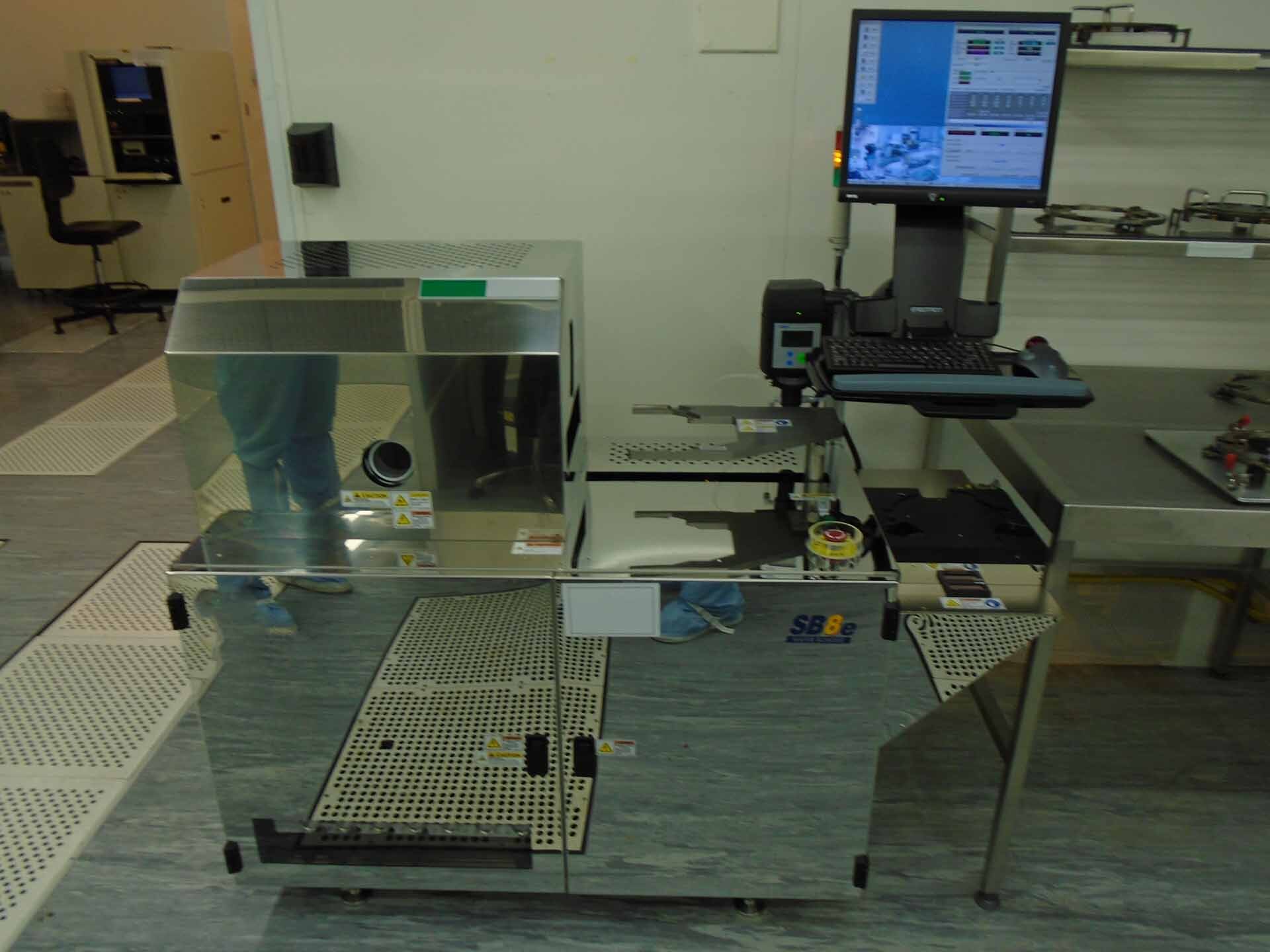

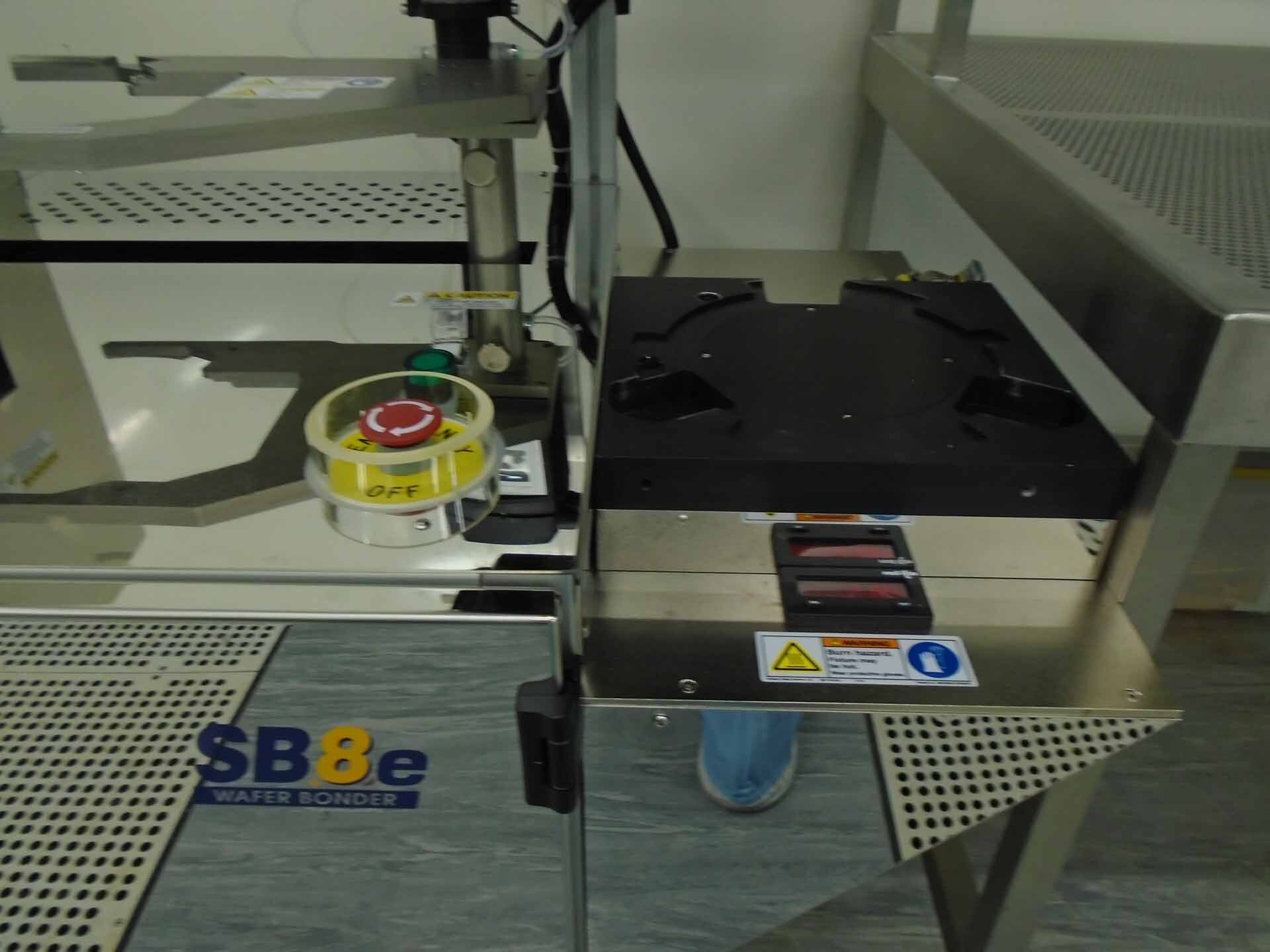

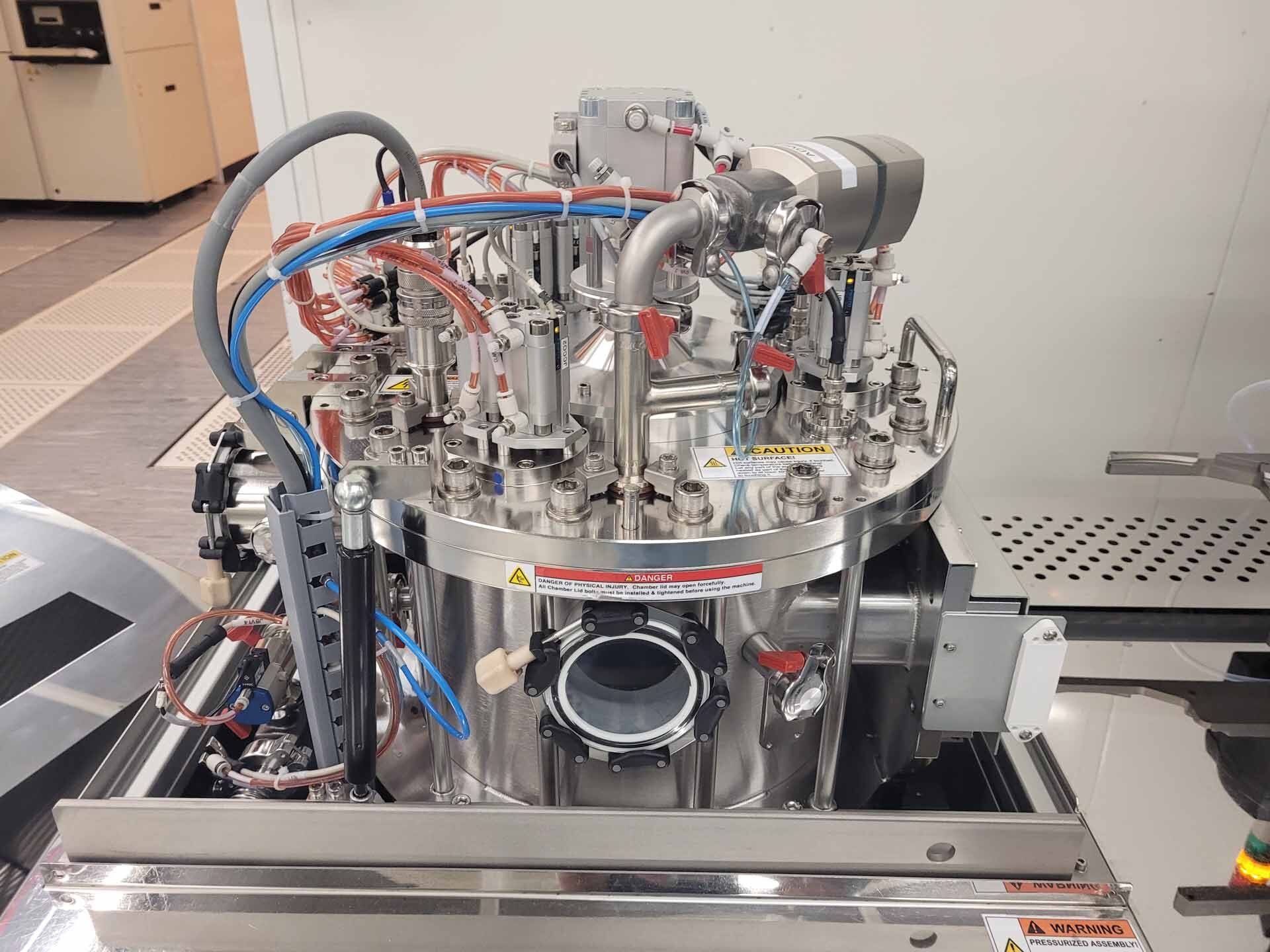

Used KARL SUSS / MICROTEC SB 8e #293621402 for sale

URL successfully copied!

Tap to zoom

ID: 293621402

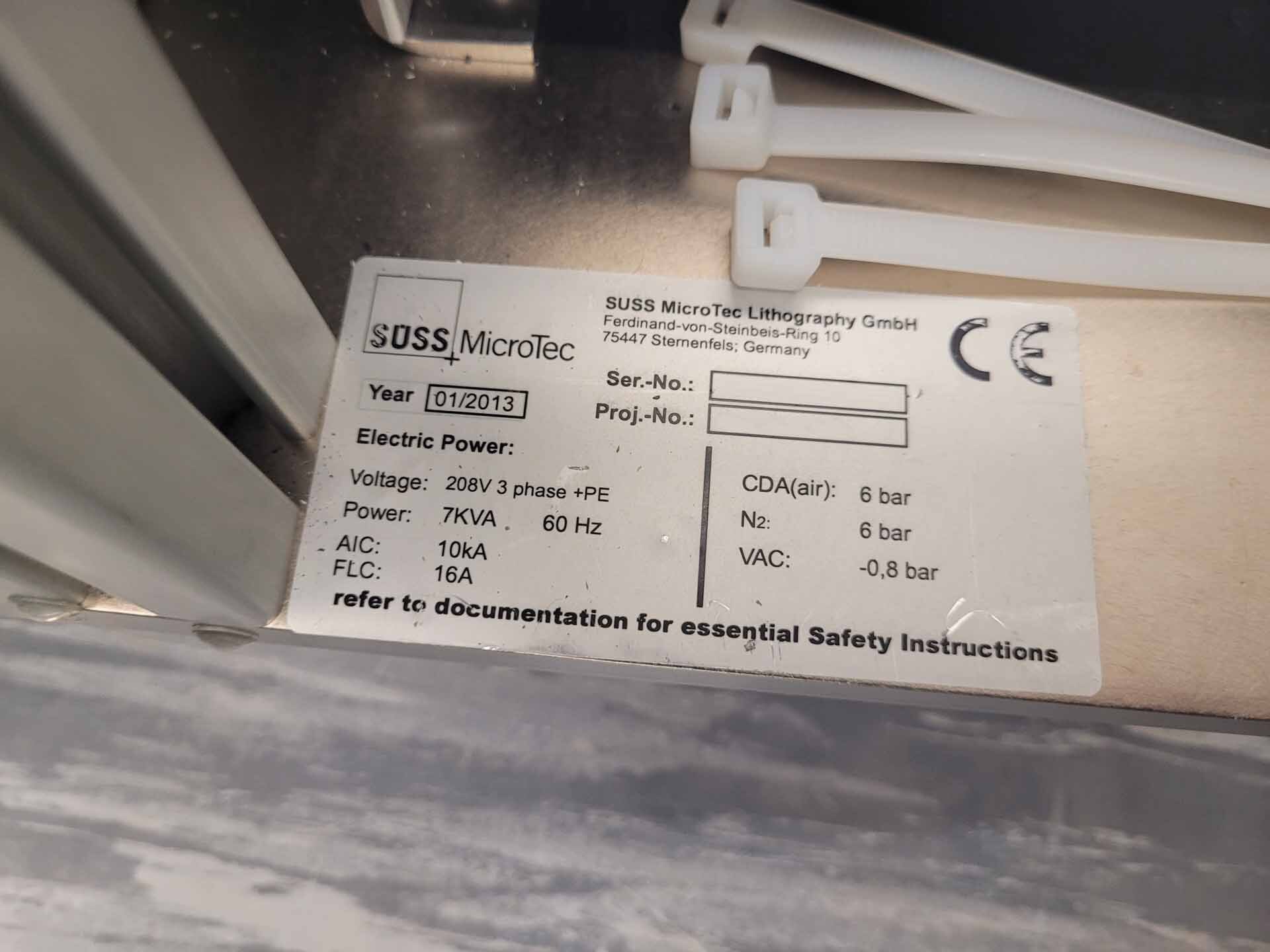

Vintage: 2013

Bonder

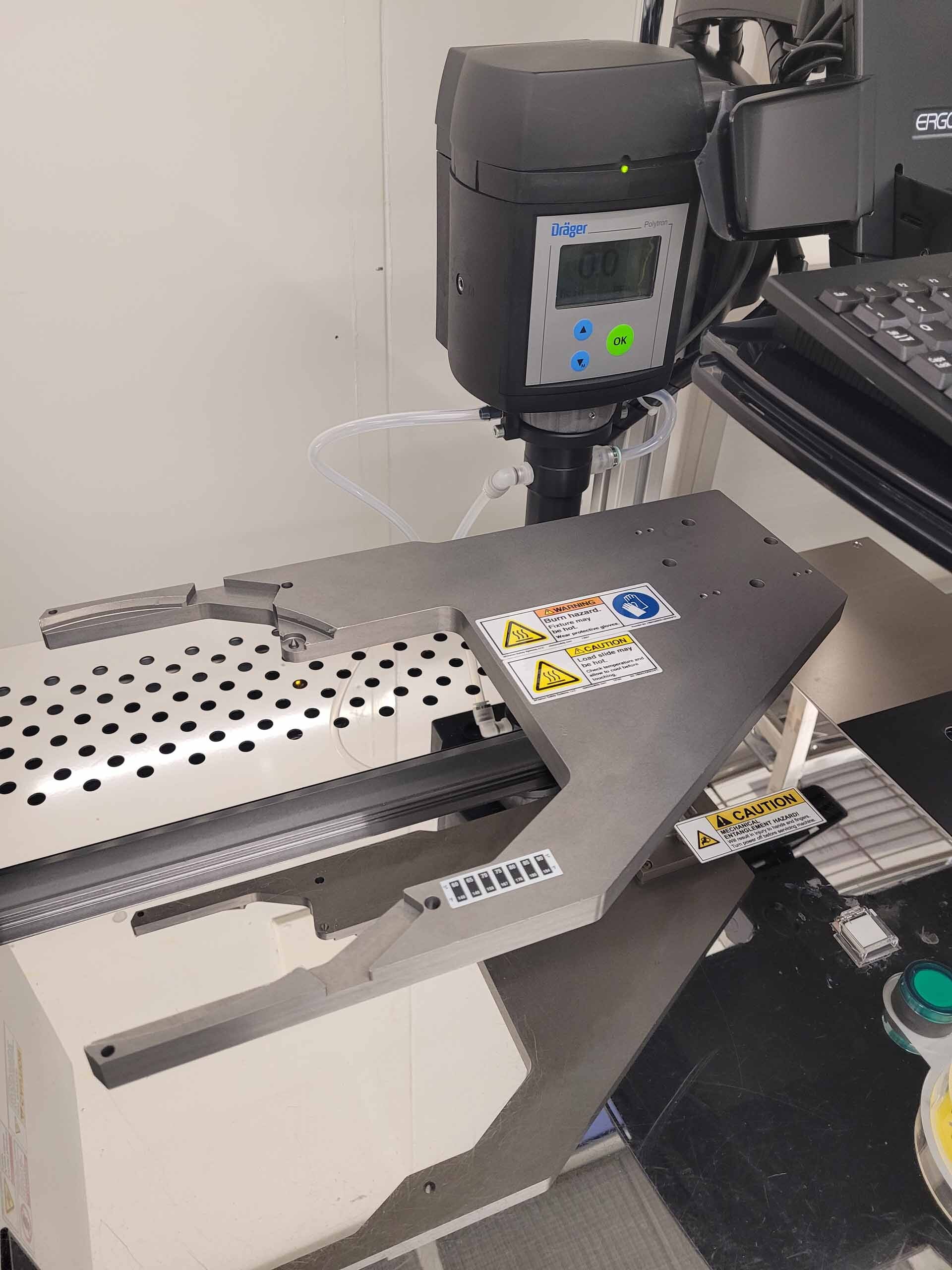

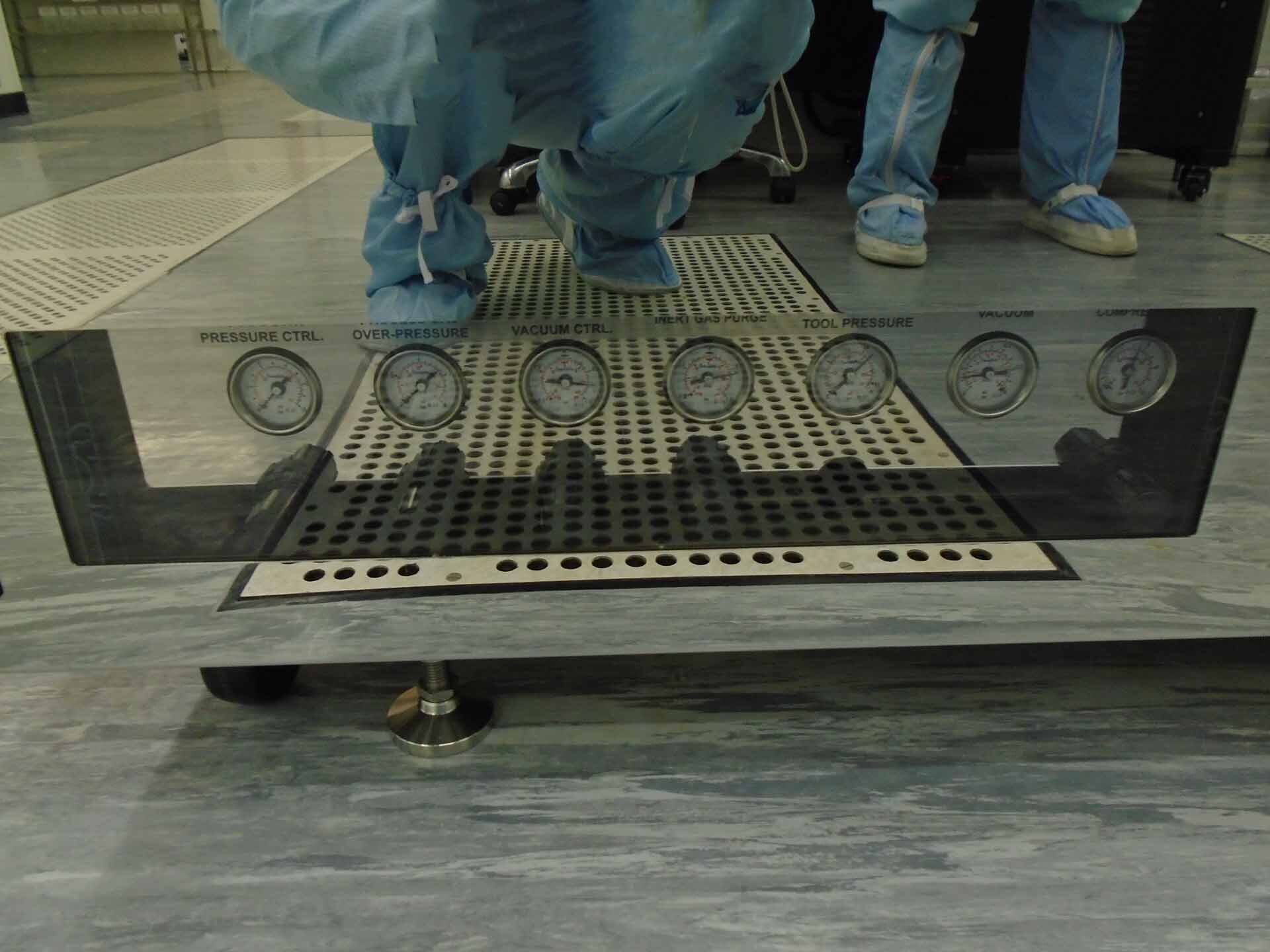

N2 Supply pressure: 102-110 psi

CDA Supply pressure: 6-10 bar

Vacuum: 0.8 bar

Exhaust: 10.6 CFM

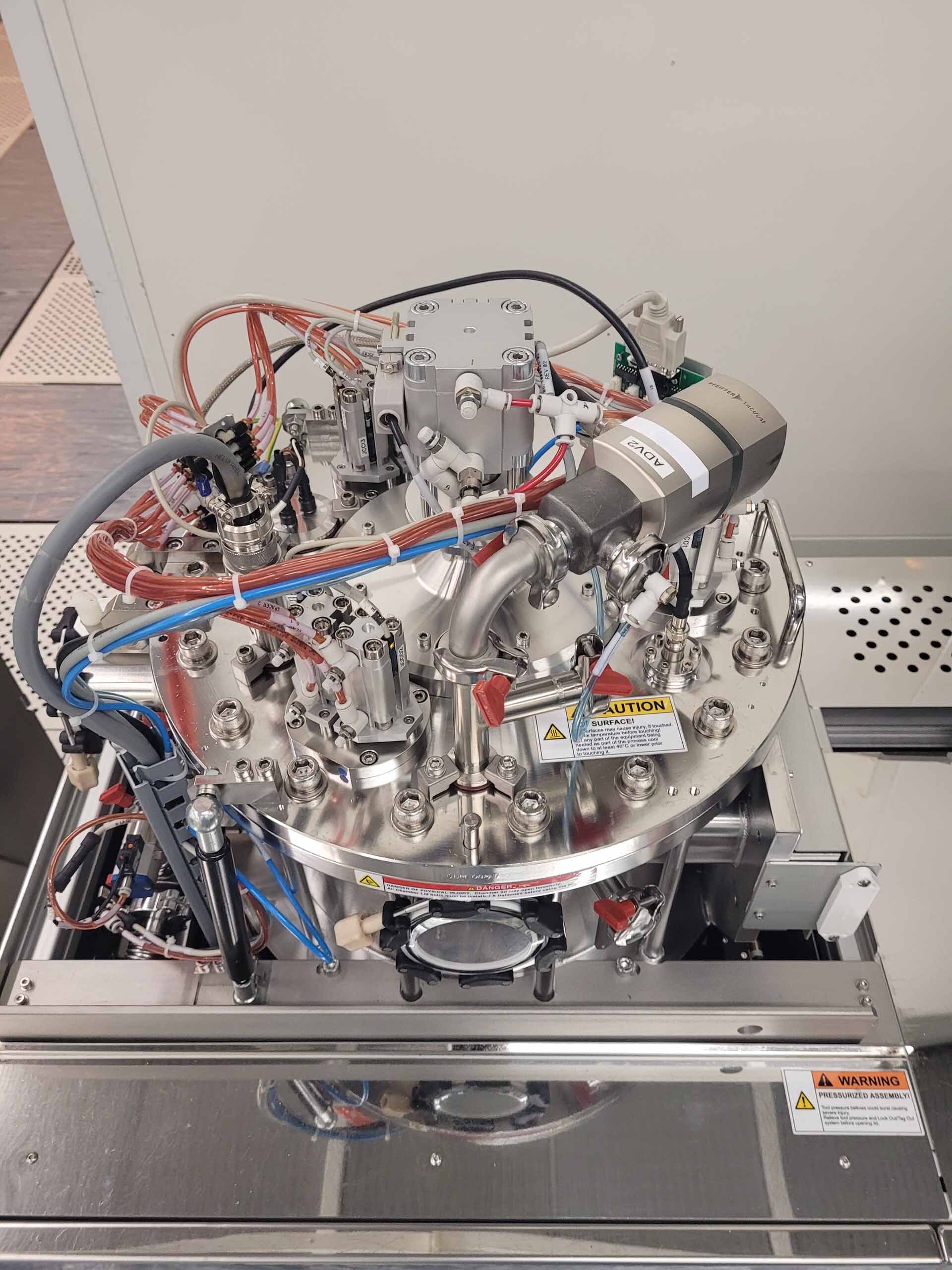

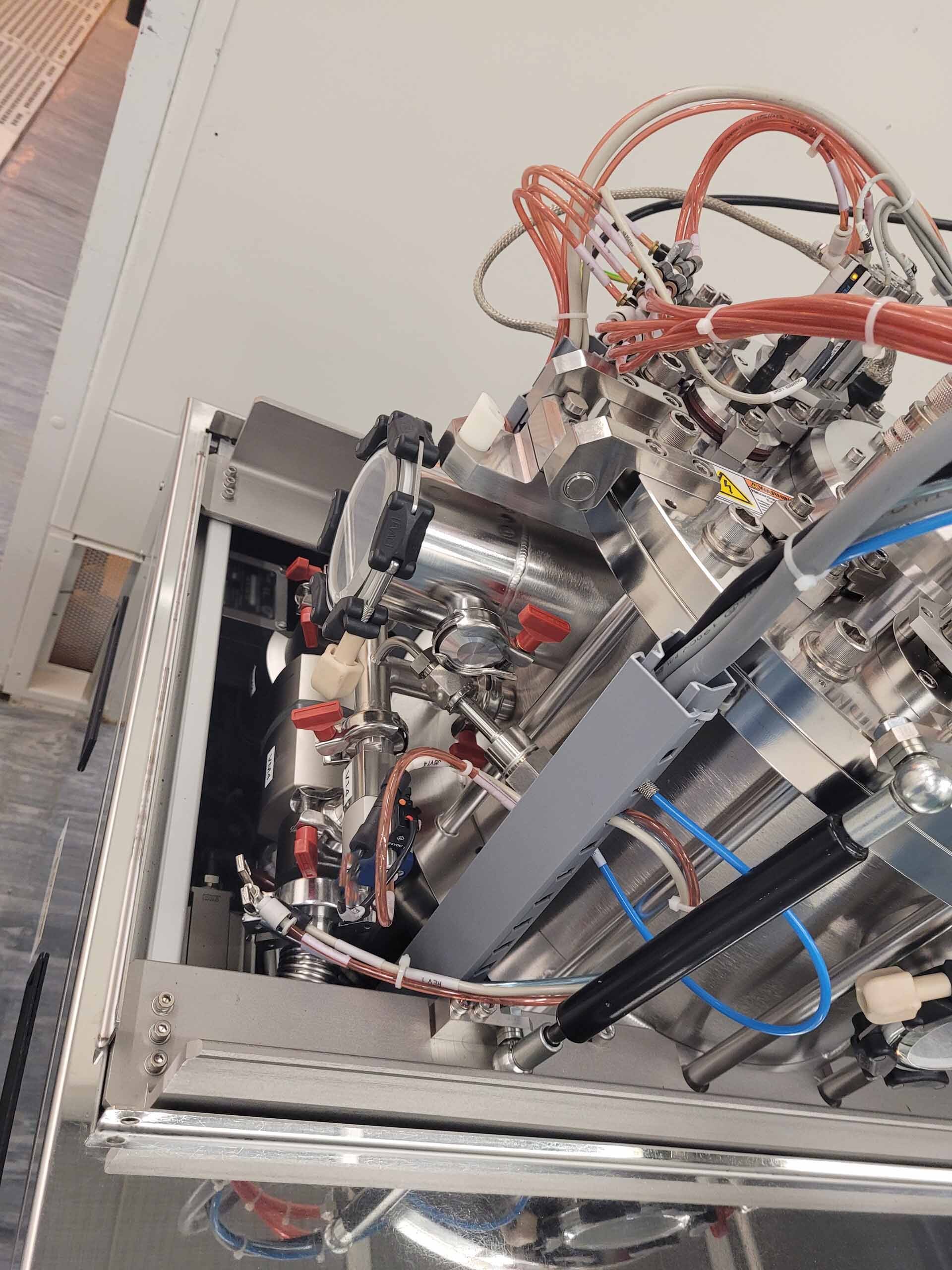

TMH262 Turbo pump

Gas ballast

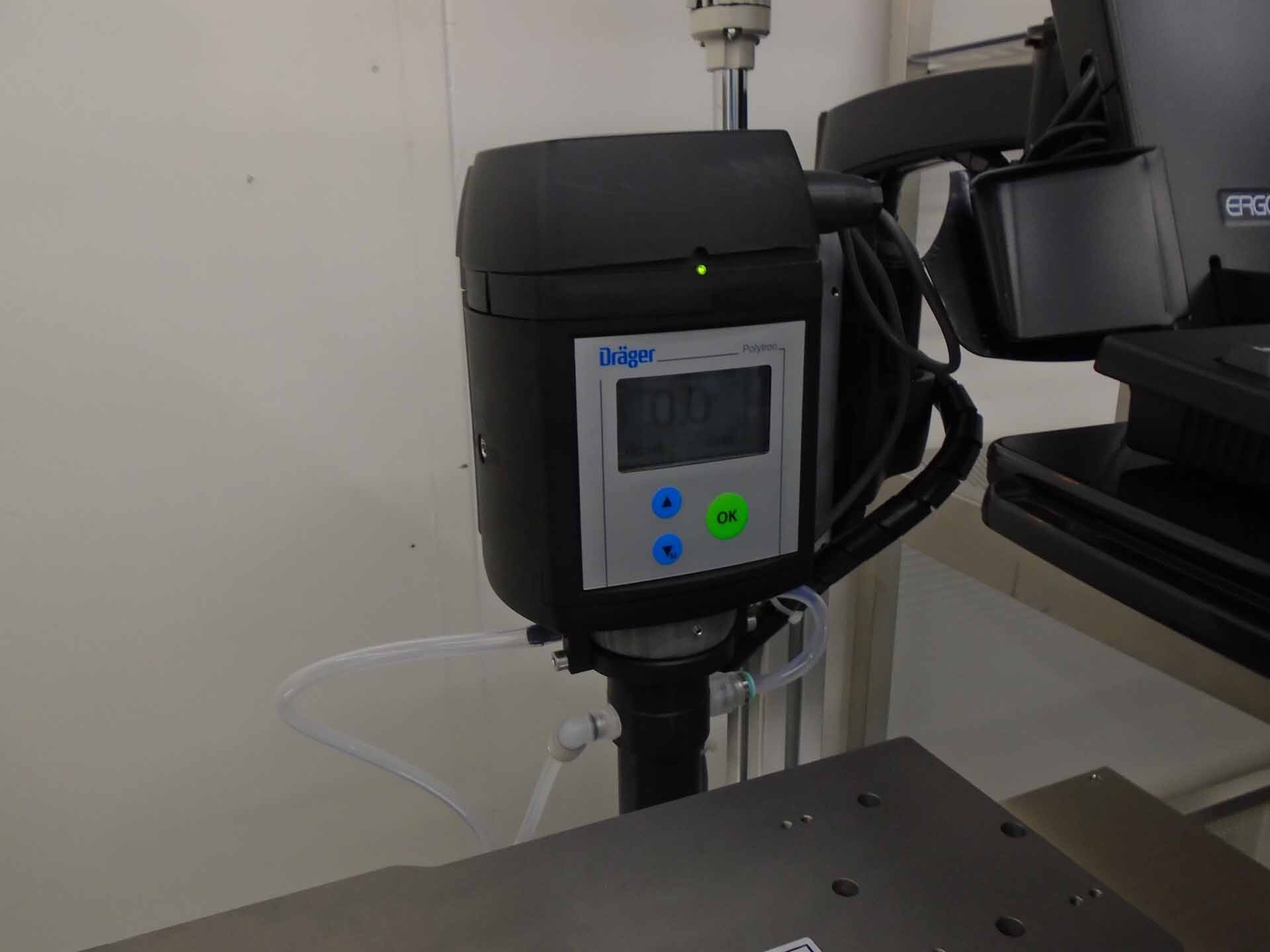

Sensor type: CH2O2

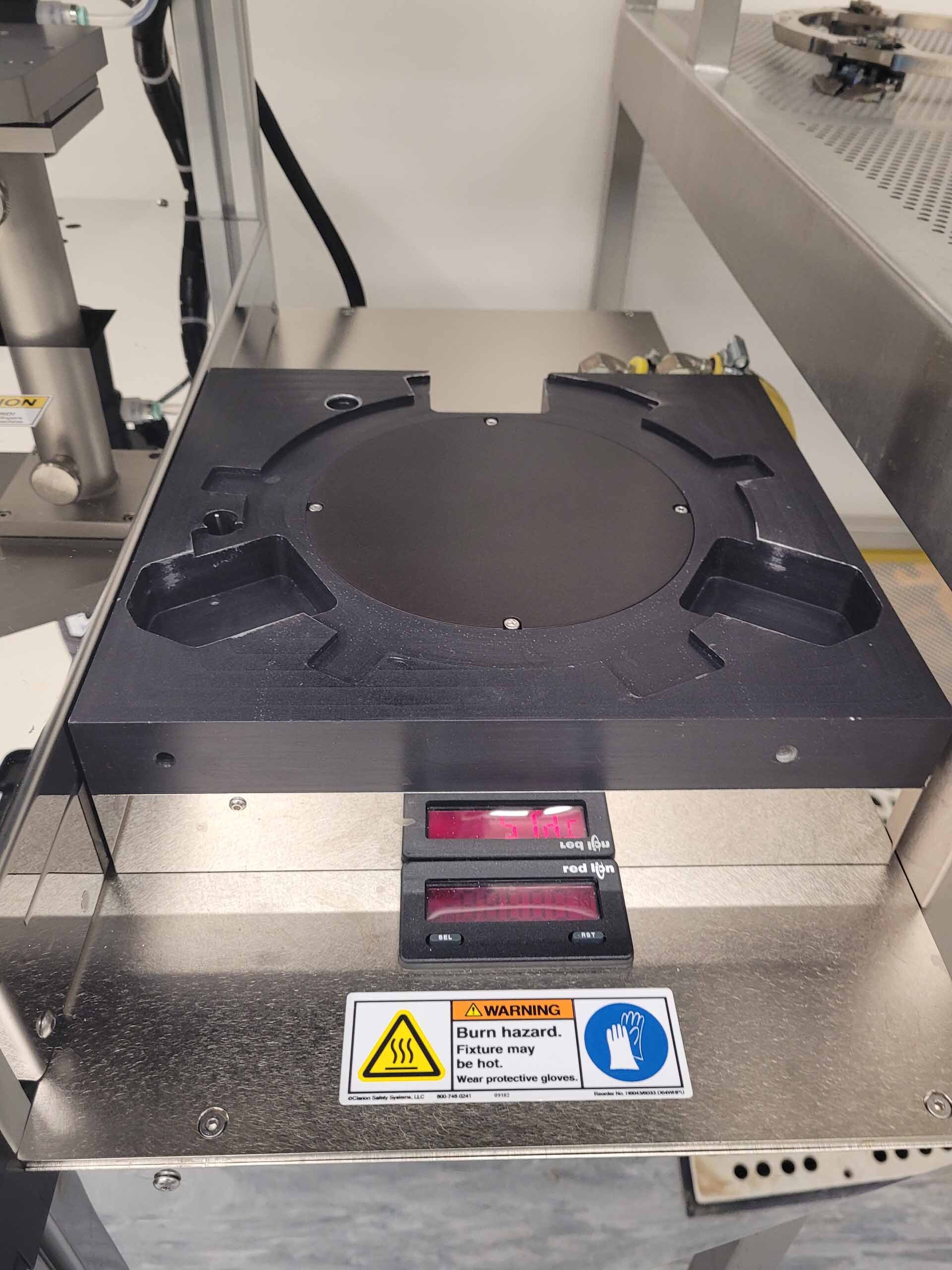

Heat:

Heater type: FHR

Thermocouples: Heater only

Maximum temperature: 600°C

Chamber:

Process gas valve installed

Bypass valve installed

Purge gas valve installed

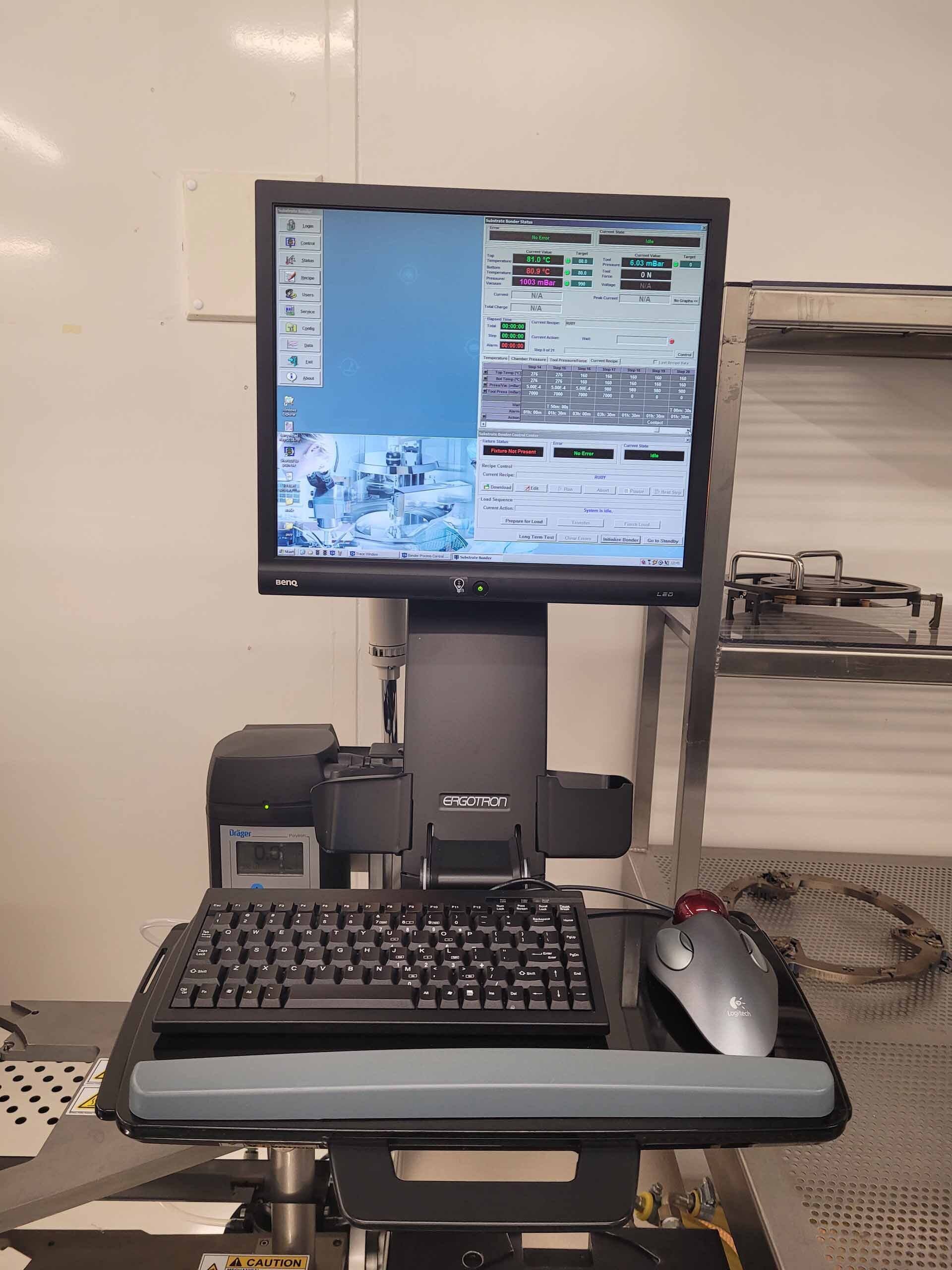

Temperature:

Bottom temperature:

Substrate maximum: 500°C

Substrate unload: 300°C

Substrate idle: 80°C

Heater maximum: 500°C

Top temperature:

Maximum: 500°C

Unload: 300°C

Idle: 80°C

Heater maximum: 550°C

Acid bubbler:

Parameter name / Component / Typical setting

N2 Bubble pressure / N1A / 1.52 bar

N2 Bubble flow / P1A / 5 LPM depends on concentration

N2 Purge pressure / N2A / 1.81 bar

N2 Purge flow / P2A1 / 50 LPM depends on concentration

Inlet pressure nitrogen / B10 / 4.5 bar (min)

Safety pressure / B8B / 0.50 bar (max)

Tool exhaust sensor / S51 / 100 Pascal

Acid bubbler exhaust sensor / S52 / 100 Pascal

Power supply:

Voltage: 3 Phase, 208 VAC, 4 Wires

Frequency: 50/60 Hz

Power consumption: 9 kVA

Current: 25 Amps

2013 vintage.

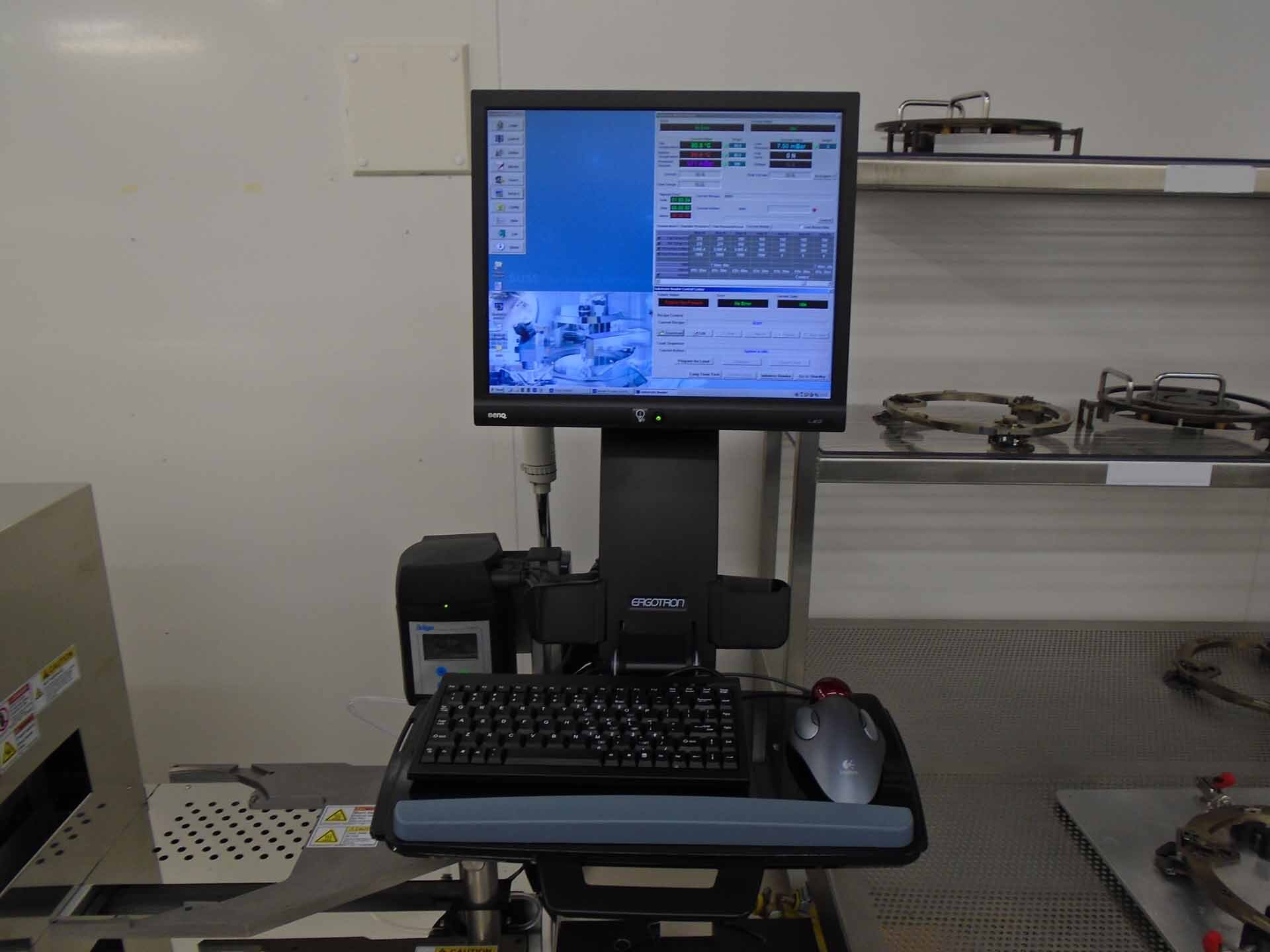

KARL SUSS / MICROTEC SB 8e is a semi-automatic, 8-inch device used for die bonding and metal bonding applications. It is a benchtop system that uses floating heated die trays, a heated lead frame, a heated base, and a 24V motorized vertical positioner to achieve precise automated die and metal bonding placement. MICROTEC SB8E features a digital display for easy adjustment of temperature, speed and pressure settings. These settings can be programmed for individual die and metal bonding operations, as well as repeated operations for quality assurance. KARL SUSS SB 8 E offers precision placement of die and metal material, even when it is being placed through automated operations. Its heated elements are connected to a microprocessor-controlled temperature module that helps to ensure uniform temperatures and a consistently high-quality bond. The vertical positioner allows for the precise placement of components, and the heated base ensures rapid and reliable temperature control during the placement process. The system also features a high-precision XYZ-axis with outside alignment, encoder module and illuminated microscope, making it ideal for specialty applications like wire bonding. SB 8e is a compact, versatile tool that is suitable for high-performance die and metal bonding applications. With its easy-to-use automation and integrated vision system, KARL SUSS / MICROTEC SB 8 E allows for the accurate and efficient bonding of complex parts and materials. Its high-quality build and numerous features make it an ideal choice for cost-effective and high-quality automated die and metal bonding processes.

There are no reviews yet