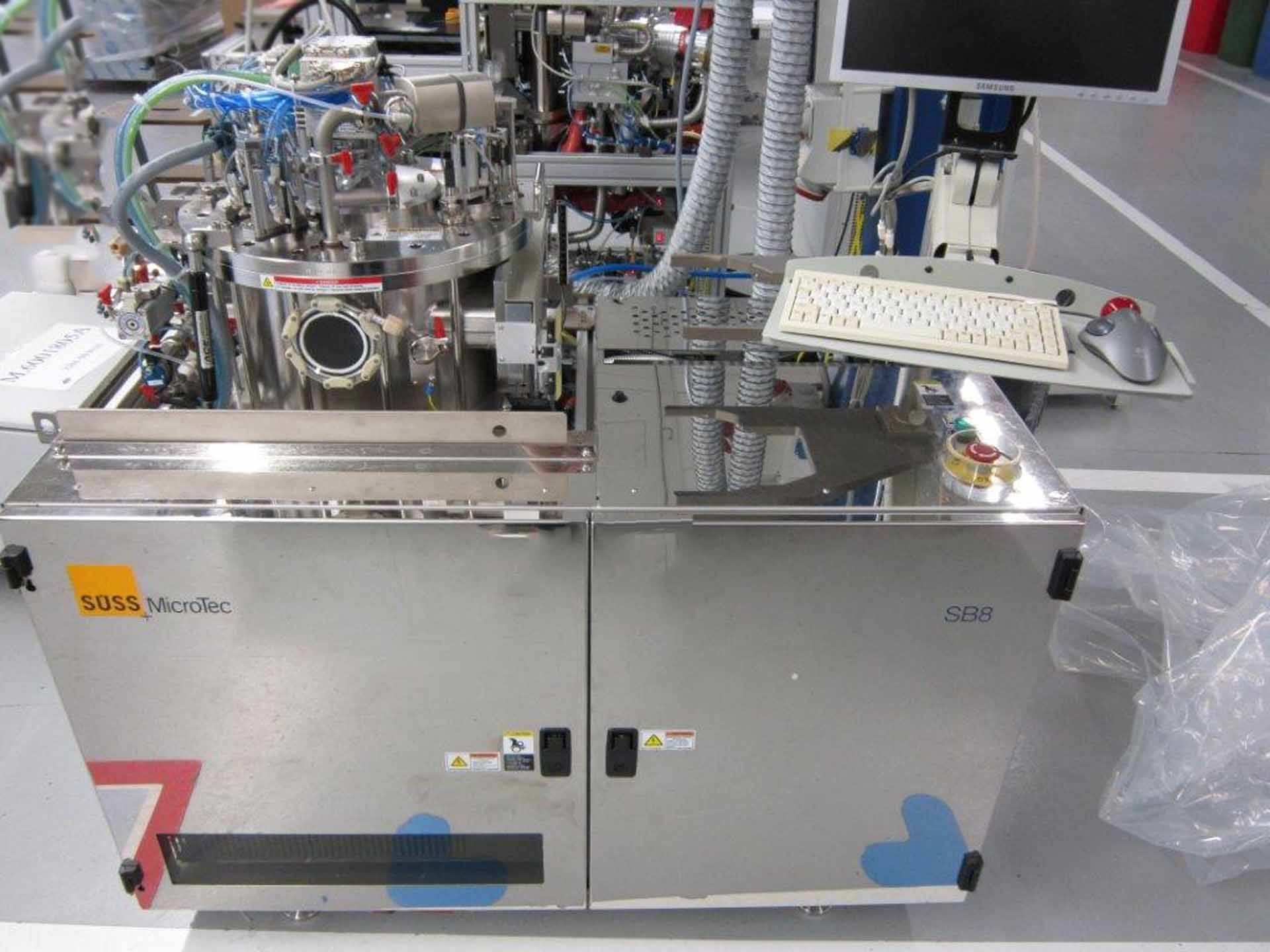

Used KARL SUSS / MICROTEC SB 8e #9212773 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9212773

Wafer bonder

P/N: 100059734

Bonding of aligned substrates: 4"-8" in diameter

Base machine specifications:

Aligned wafer transport fixture: Manual loading / Unloading

Automatic process data recording with selectable interval

Polished stainless steel cabinet

Motorized Z axis for automated wafer stack thickness compensation

Transport fixture loading slide

Process chamber:

Electro polished process bond chamber with controllable insertion of process gases

Automated open / Close process chamber door with integrated safety light barrier (VAT door)

Automatic chamber purge during process door cycling to avoid chamber

Media supplies:

Clean dry air: 6 Bar

Process nitrogen: 7 – 75 Bar

Vacuum 100 mbar (abs) for pressure bond tools

Control system:

User & maintenance interface

Operating system: Windows

Network connection: Ethernet

External communication: USB Connection

PC Flat panel monitor with keyboard and trackball

Hot chuck(s) SB8 GEN2 with industrial temperature controller

Industrial temperature controller for enhanced precision temperature control

Rapid setup of temperature ramps with fast controller profiling & control of heaters

Lower hot bond chuck with temperature control from ambient to 500°C

Resistive heater with active air cooling

Temperature control: +/- 3 degrees

Programmable temperature ramps

Temperature uniformity: +/- 2.0%

Heating / Cooling performance:

Heating: 30°C /min

Cooling up to 28°C/min machine and configuration depending

Kit, upstream control:

For bonding from atmospheric pressure down to of 5e-5m bar with turbo pump option

Downstream controller:

Pressure range: Absolute 1 - 1000 mbar up to 3000mbar with over pressure kit option

Flow between 05 & 13 l/min (Depending on pressure) adjustable by manual valve

Signal status tower:

P/N: 100075936SB

Light tower with three lights & buzzer for machine status indication

Lights configured & customized

Multiple process gases kit:

P/N: 100059766

Automated gas selection for up to 4 process gases (N2 Plus three gases)

Recipe controlled automated selection of one of four process gases

Configurable process gas names

Supports all inert gases

Forming gas with a maximum concentration of 5% & synthetic Air (80%N2 20%O2)

Clean PFA teflon process gas tubing

Turbo pump with scroll pump:

P/N: 100059752

For high vacuum to 5e-5mbar

Turbo molecular pump

Scroll pump type: EDWARDS XDS

Dry lubricant free

Chemically resistant

Clamp / Spacer unit with sequential spacer removal:

P/N: 100060409

Hardware & software for individual spacer removal & clamp arm control

Options: Bonder to lift one clamp

Spacer force free and to set the clamp again

Programmable actuation, improves post bond alignment capability

Standard tool force generation:

P/N: 100059765

Option: Bonder to control the bond force via cascaded two point control system

Bond force values:

Minimum force: 300N

Maximum force: 20kN

Maximum ramp rate: Up to 3.7kN/min

P/N: QW1001312

Force range capability 500N - 20kN with 6" / 8" wafer

Spring loaded center pin: Diameter 12mm

Heater temperature range: Ambient plus 10°C up to 500°C

P/N: W1002902

SiC Pressure plate and sandwich plate(upper & lower): 8", Diameter

Pressure plate: (3) Cut outs for spacers and clamps

P/N: W1023794

Compatible with SUSS MicroTec bond aligners, for 8" wafers

Clamp arms included

P/N: W1026899

TiN Coated stainless steel: 0.2 mm thick

Power requirements:

380-400 VAC, 20 A, 50 Hz

200-208 VAC, 25 A, 50/60 Hz.

KARL SUSS / MICROTEC SB 8e is a fully automated, multi-functional, medium-scale die bonder. It is equipped with a fully automated vision system to ensure precise placement of the die to the substrate and its corresponding wire bonding processes. This bonder utilizes two wire bond heads that can be changed between ultrasonic and thermocompression. The bonder also has a fully integrated heating stage with an adjustable temperature range up to 400°C to ensure efficient and reliable bonding. MICROTEC SB8E offers a very large working platform (195 x 145 mm) and an adjustable bond head height (up to 60 mm). This feature makes it suitable for different package types and application variations. The low power consumption (300W) makes it easy to use and cost effective while providing a reliable and accurate bonding process. The bonder also features an automatic solder fluxing application as well as the option to incorporate additional wire bonding techniques such as gold or silver wire bonding. The bonder is also equipped with an adjustable wafer chuck and vacuum cleaning system for precise placement of the die to the substrate. It can also be configured for different power supplies up to 3000V. Overall, KARL SUSS SB 8 E bonder is a powerful bonding machine with advanced features, suitable for a wide variety of applications in the semiconductor industry. The bonder can be used for prototyping, wafer level packaging (WLP), and low- to high-volume production. Thanks to its user-friendly design, intuitive interface, and robust construction, the bonder is a reliable tool for automated die attach processes and wire bond applications.

There are no reviews yet