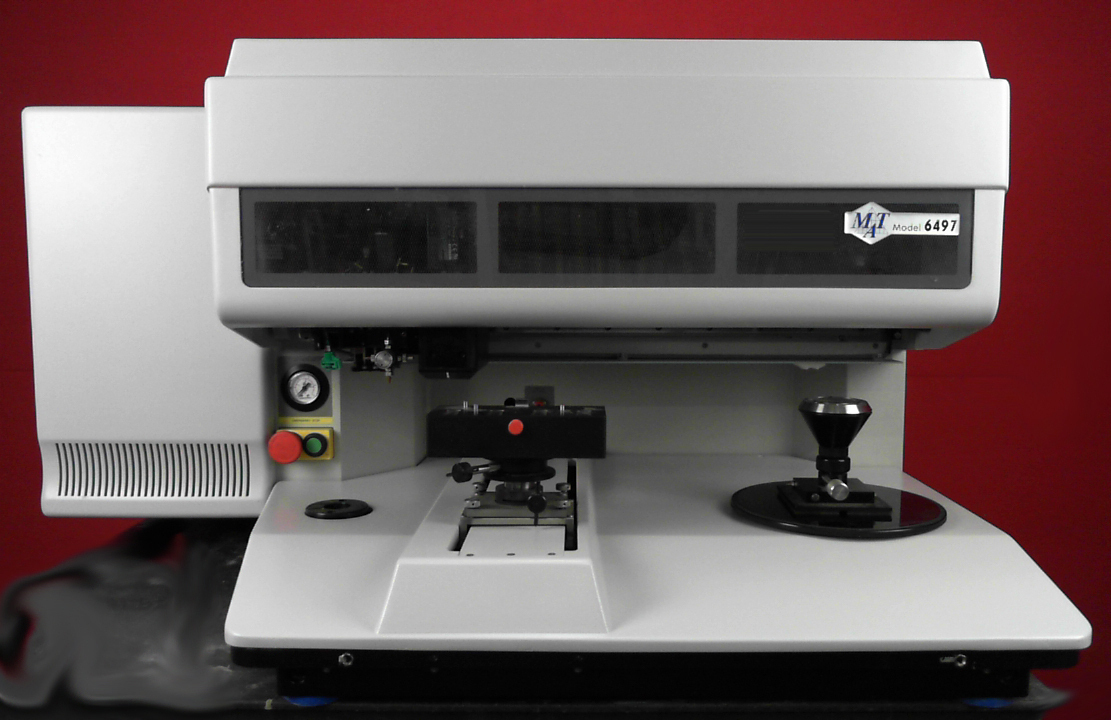

Used MICROASSEMBLY TECHNOLOGIES / MAT 6497 #9084254 for sale

URL successfully copied!

Tap to zoom

MICROASSEMBLY TECHNOLOGIES / MAT 6497 is an automated monolithic die and package bonded equipment for joining die onto substrates, embedded passive and active components, and flip-chip technology. This fully automated system makes use of high-speed, high-precision robotics to precisely adjust parts and materials for optimal assembly. Furthermore, it is also capable of combining laser-site welding and precision soldering, providing superior bond strength and reliability. MAT 6497 comes with a comprehensive suite of control and software automation tools that give users comprehensive control of assembly operations. This robust unit is highly configurable and can be tailored to fit any specific application. This flexibility helps account for the various complexities of today's manufacturing process. MICROASSEMBLY TECHNOLOGIES 6497's advanced software also provides an optimised thermal profile during the assembly process, ensuring precise temperature control for a complete die and package bonding operation. The superior speed and accuracy of 6497, along with its comprehensive range of software automation tools, make it ideal for testing and production environments alike. It is also capable of being integrated with existing materials, components, and machines, offering great flexibility when it comes to customising assembly operations. MICROASSEMBLY TECHNOLOGIES / MAT 6497 package bonding machine is also equipped with various safety systems that help to ensure that no operator or bystander is placed at risk during the assembly process. This includes an on-board safety enclosure, a proximity sensor, and emergency stop buttons. In addition, the tool can be used in either low- or high-temperature environments. To sum up, MAT 6497 is an advanced robotic asset that can be used to efficiently and reliably join die onto substrates, embedded passive and active components, as well as flip-chip technology. It is equipped with a range of software automation tools that give users comprehensive control over the assembly process. Furthermore, it also features several safety systems to help protect operators and bystanders, as well as its high temperature tolerance to operate in different environments.

There are no reviews yet