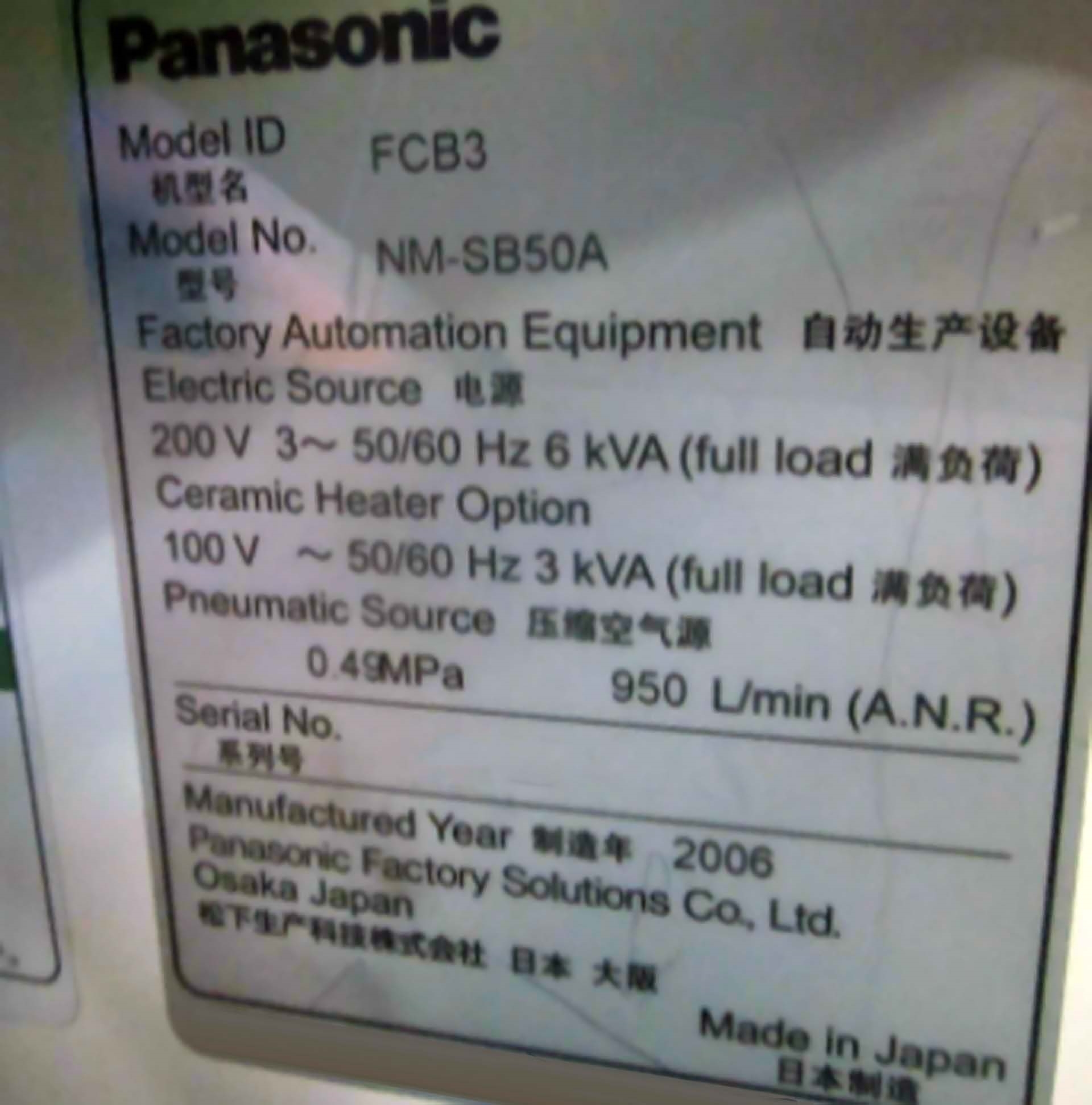

Used PANASONIC FCB3 #9251928 for sale

URL successfully copied!

Tap to zoom

ID: 9251928

Wafer Size: 12"

Vintage: 2007

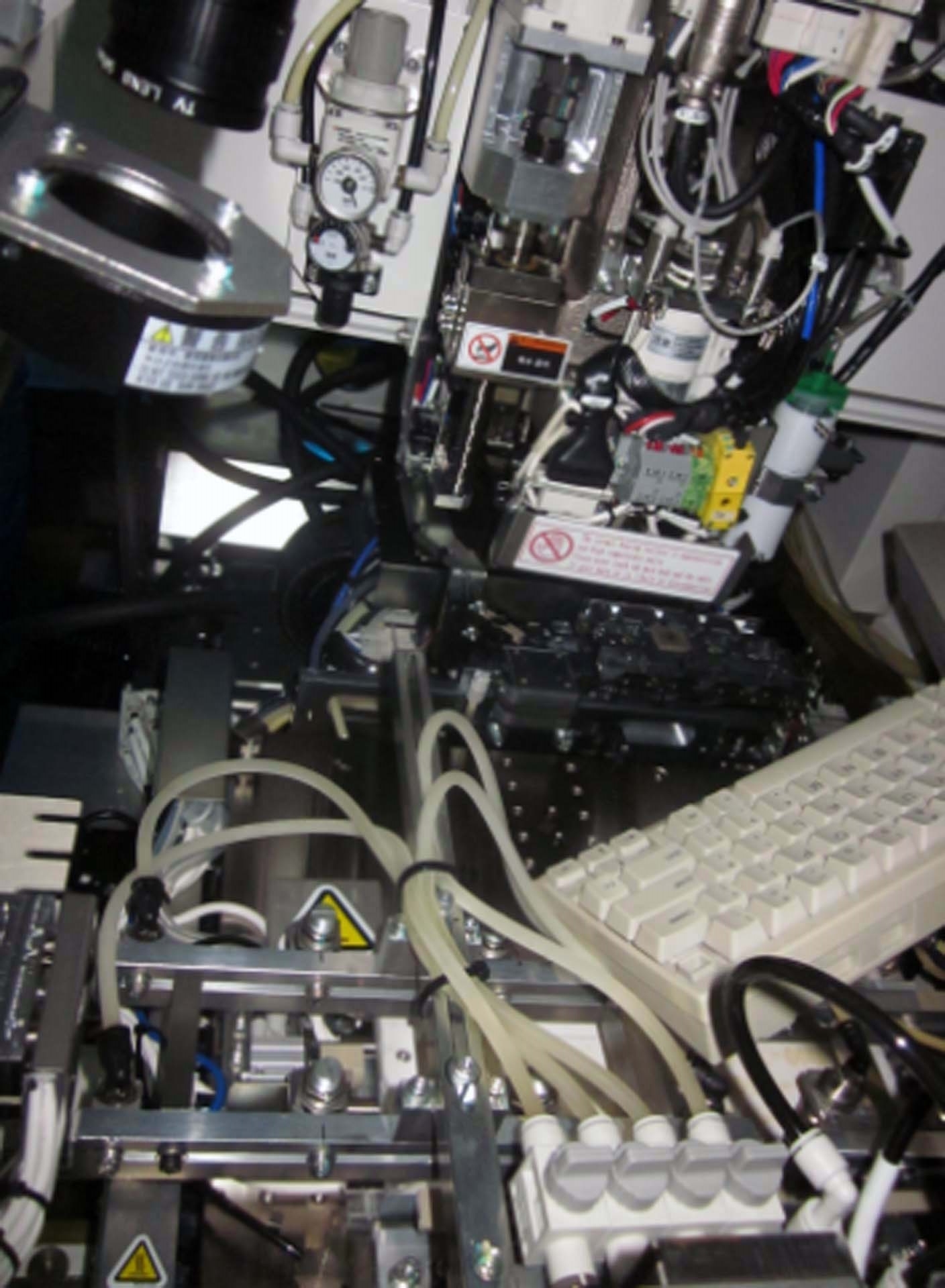

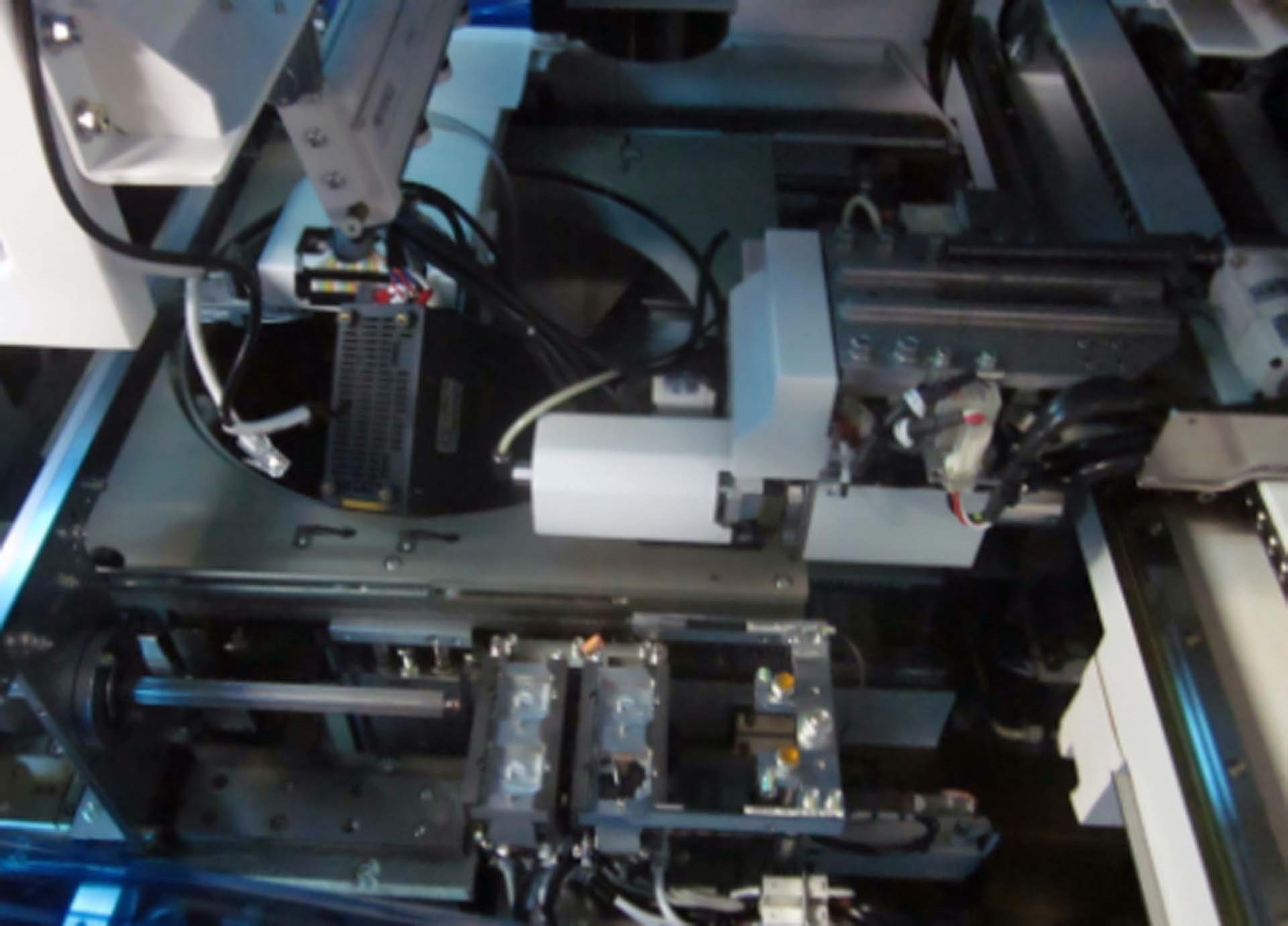

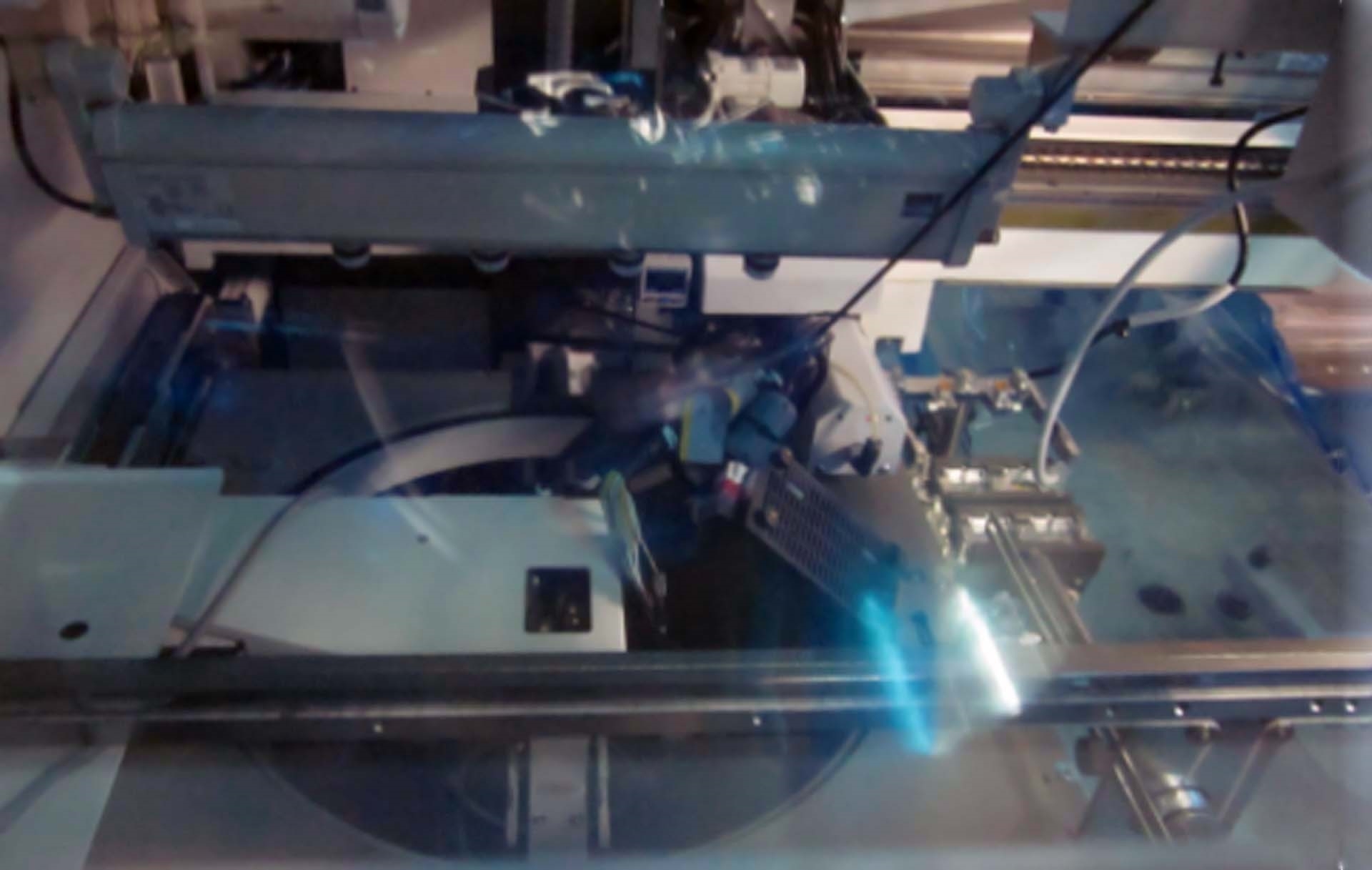

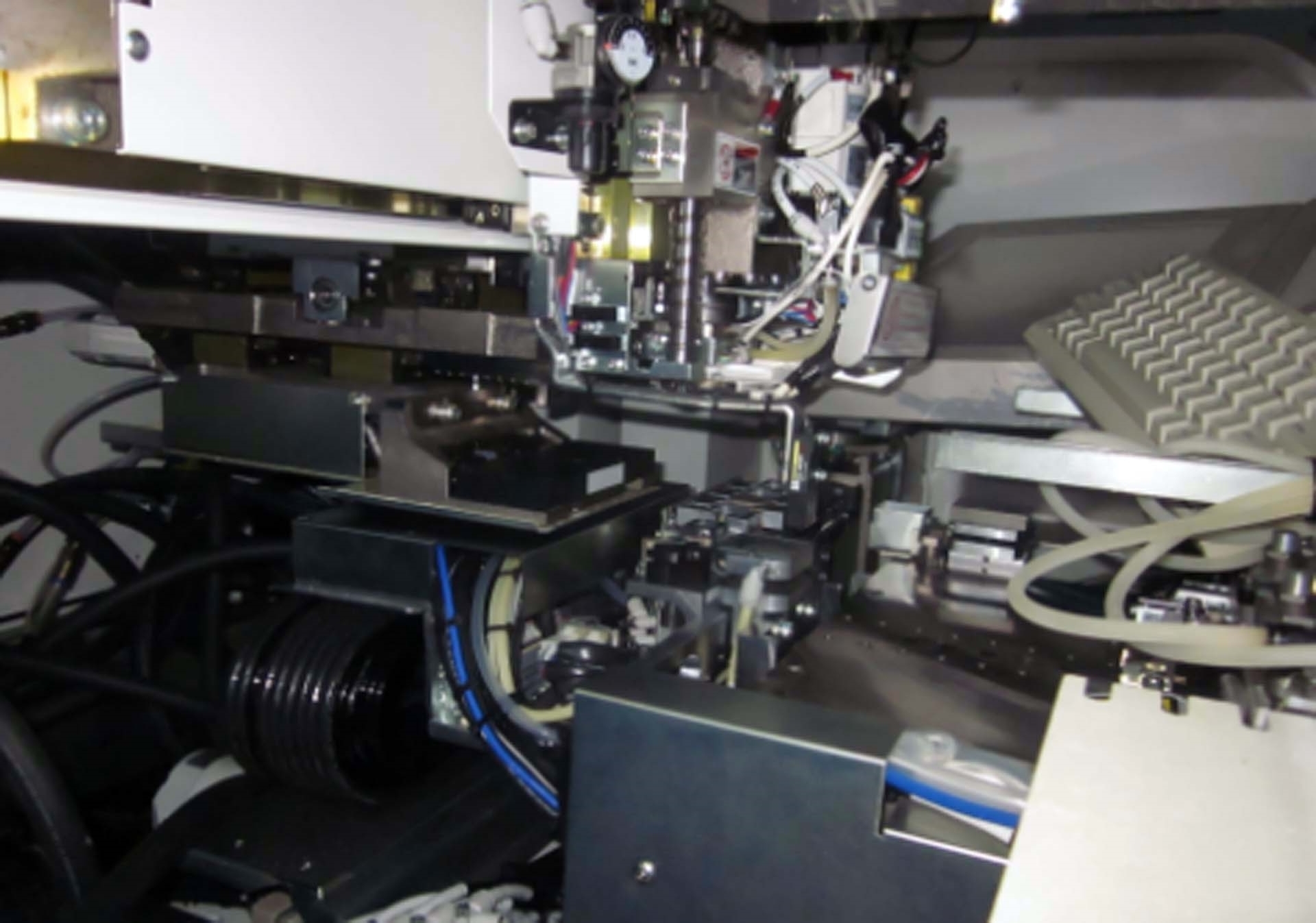

Flip chip bonder, 12"

No Hard Disk Drive (HDD)

2006 vintage.

PANASONIC FCB3 is one of the most advanced thermo-compression bonders manufactured by PANASONIC. This bonder provides an innovative solution to providing efficient and high quality interconnections and connections among various electronic components. It is an ideal solution for a wide variety of industrial and electronics applications. FCB3 bonder utilizes advanced heat compression technology for efficient bonding of various components. The advanced thermal control technology enables highly precise bonding pressures and temperatures that ensure reliable, strong connections. PANASONIC FCB3 also features an automated motion control equipment which allows precise repeatable motions for precise bonding. FCB3 is equipped with a closed-loop temperature control system featuring a dual-wire, thermo-coupled heating unit for consistent and efficient thermal energy. This ensures optimal temperature management and eliminates risk of over-heating. The temperature range for the bonder is adjustable from 50°C to 300°C. PANASONIC FCB3 bonder accommodates various dies and is easily reconfigurable for different components, which allows for greater user flexibility. It also supports multiple placement zones with a wide range of positioning accuracy that enables precise component alignment. The machine also uses a precision pressure control tool which adjusts the cycle time according to different materials and heat cycles, providing reliable and repeatable results. The bonder offers several safety features, including a temperature auto-cutoff asset and an overheat protection model. These safety features help protect the components to be bonded as well as the operator. The equipment also includes emergency stop features that can be activated in case of an emergency. FCB3 is a reliable and economical bonder which offers an efficient and accurate solution to laying down conductive patterns on various components. The bonder is easy to use, as it is supported by a user friendly software suite that makes selecting, placing and controlling the bonding process an effortless task. It is an ideal solution for any industrial and electronics applications where quick and reliable connections are required.

There are no reviews yet