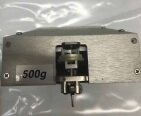

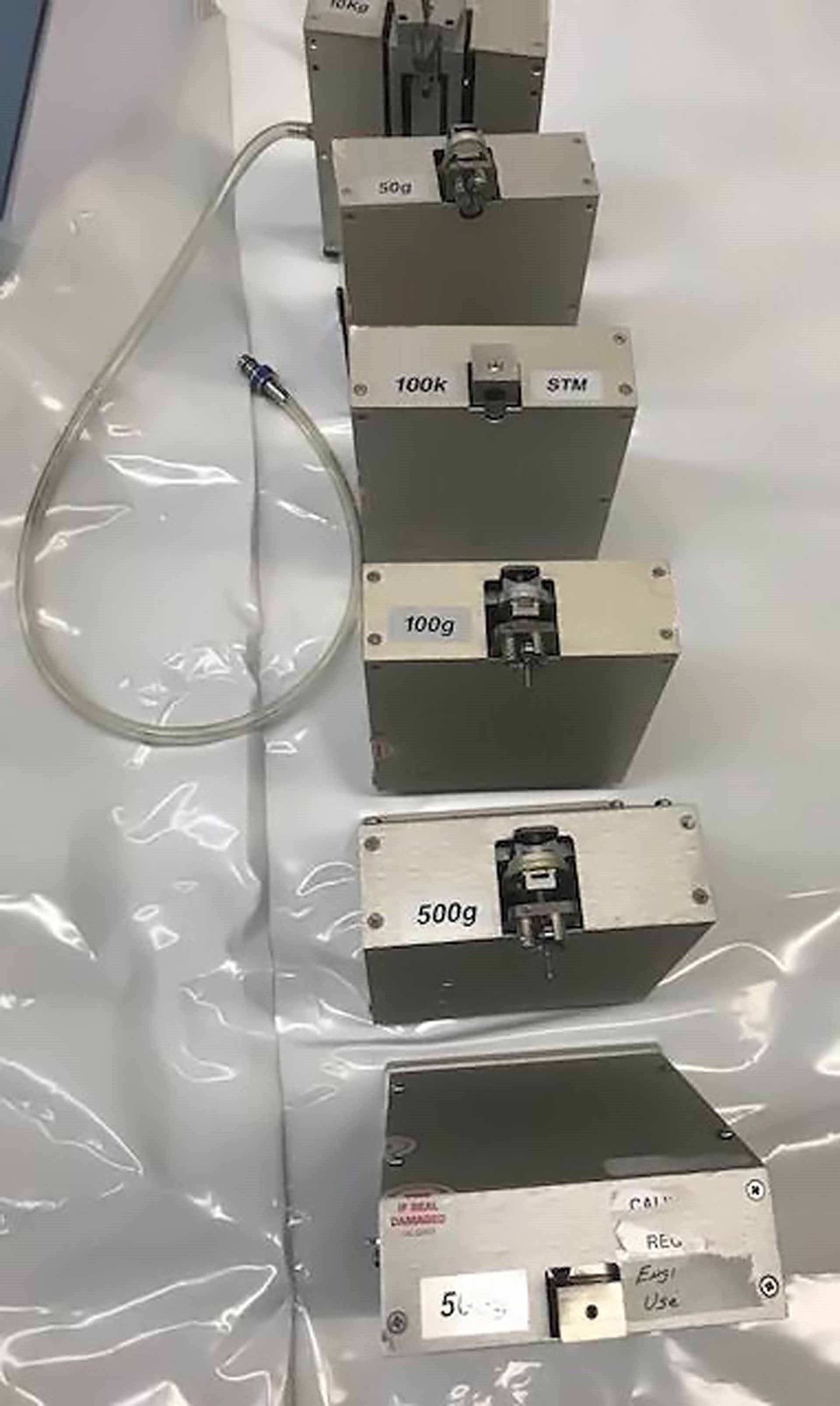

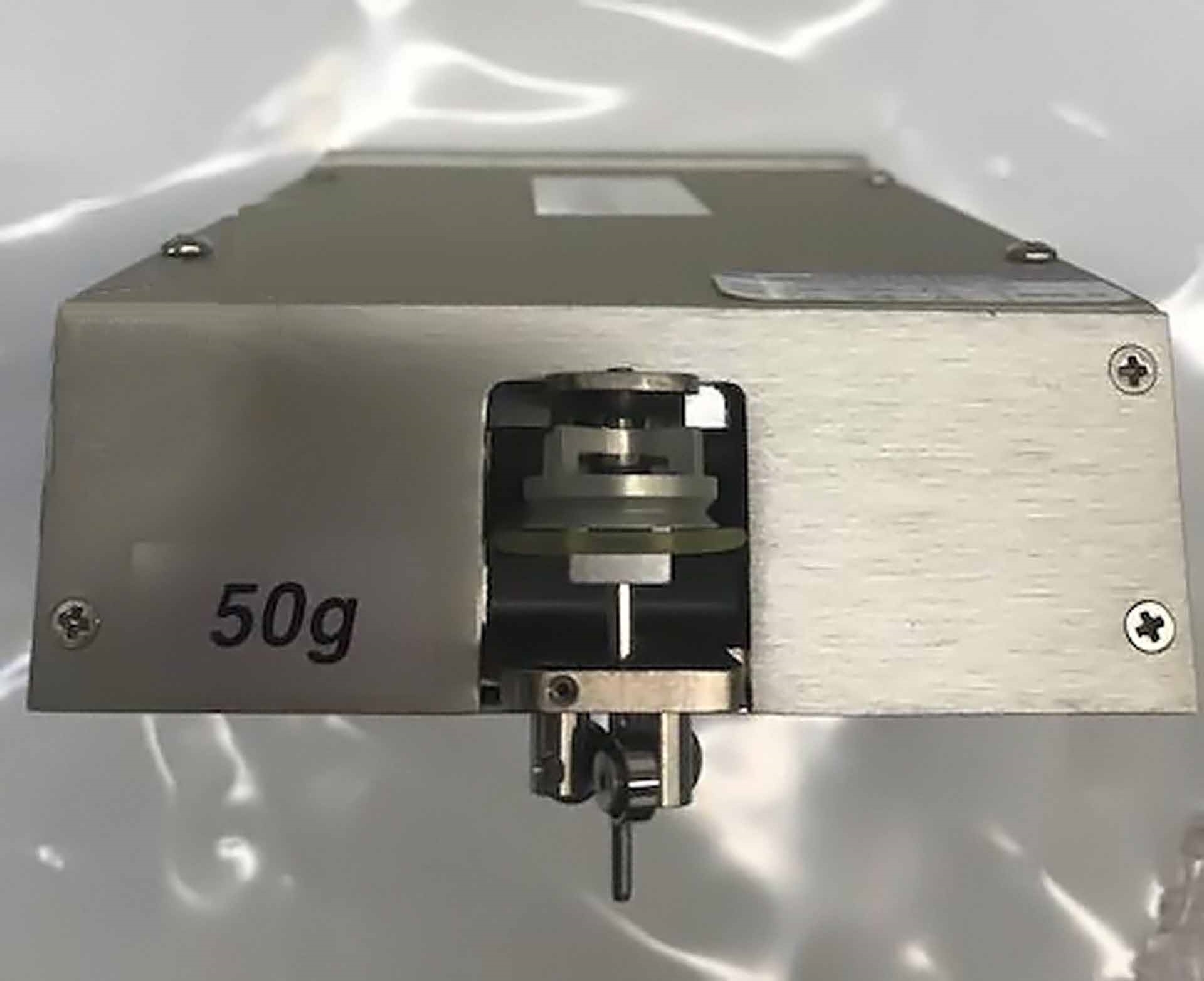

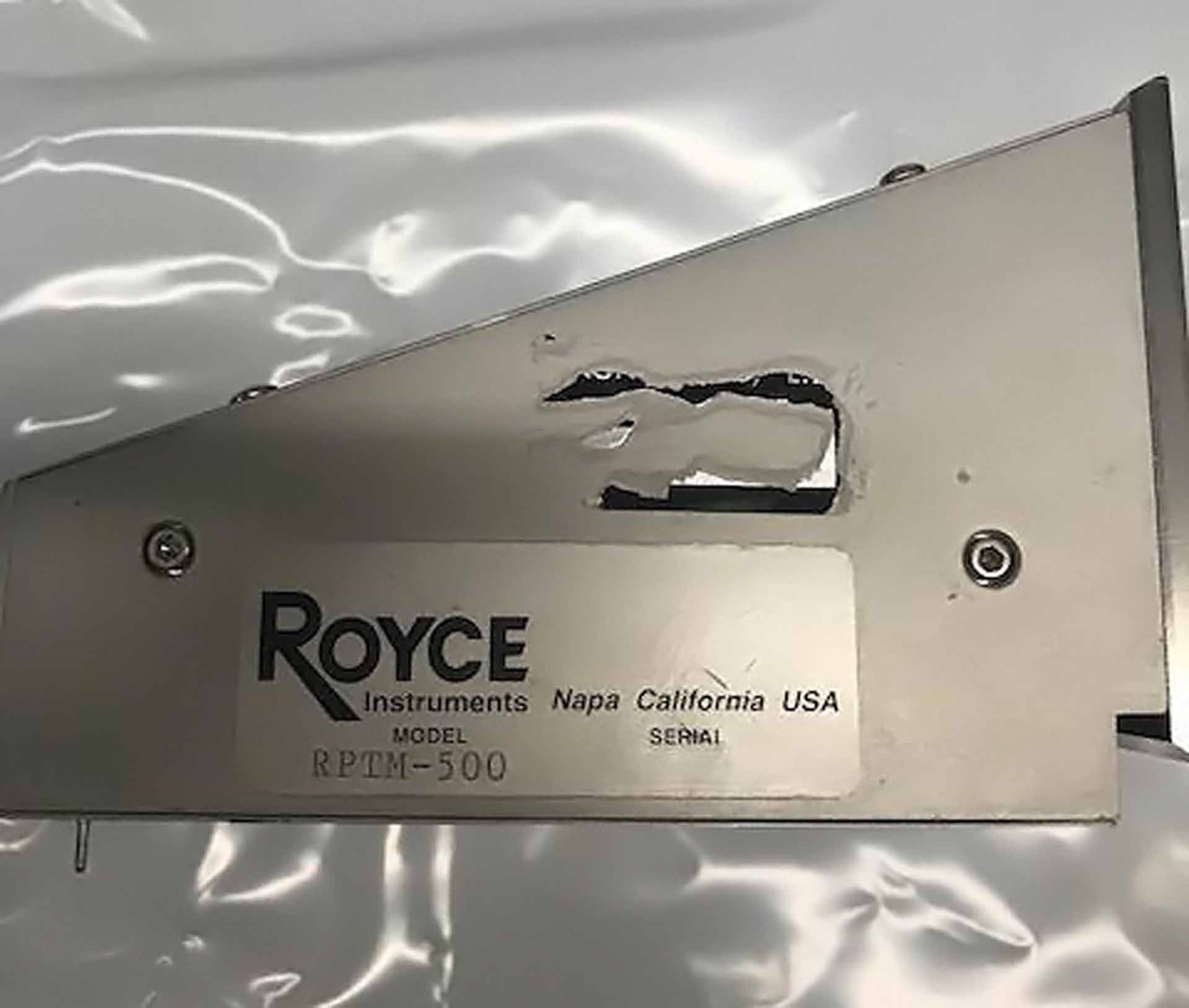

Used ROYCE 552 #9218430 for sale

URL successfully copied!

Tap to zoom

ROYCE 552 is a bonder specifically designed for the manufacturing and packaging of Lead-Free Flip Chip technology, as well as other chip carrier based products. This advanced technology bonder utilizes an electro-mechanical placement head with thermal inserter drive, providing high accuracy bonding and integration with other automated processes. It features an integrated vision system, allowing for flexible package types and a custom-designed faceplate/wafer load/unload system. This bonder is capable of producing highly reliable Flip Chip devices at speeds up to 1000 parts per hour. 552 is equipped with a variety of features that make it an ideal choice for industry professionals. This model features a fully programmable insertion head with precise control of all insertion parameters for improved consistency. It also offers user friendly software for easy setup of jobs, visual inspection, and detailed statistical regression testing of assembled components. The air operated lead screw and ball screw drive offers unparalleled accuracy and productivity. Furthermore, it includes a variety of tooling and nozzles for a variety of applications from basic die attach to complex Flip Chip processes. The advanced capabilities of ROYCE 552 provide increased throughput, quality, and ROI over conventional bonders. It is designed to withstand manufacturing conditions, such as long-term operation and environmental conditions. It also has an onboard heater to achieve repeatable and stable temperature profiles throughout the application. 552 utilizes advanced sensors and algorithms to guarantee precision bonding under high speed operations. It is also capable of placing components, such as memory chips, onto wafers with unmatched accuracy and repeatability. Its intuitive user interface allows for easy job programming and editing. Additionally, it is designed with the latest safety features in order to ensure a safe operation in the manufacturing area. ROYCE 552 was designed to maximize cost efficiency in modern chip carrier-based production, providing significant advantages in terms of yield, throughput, and quality. Moreover, it is well known in the industry for its superior bonding performance and durability.

There are no reviews yet