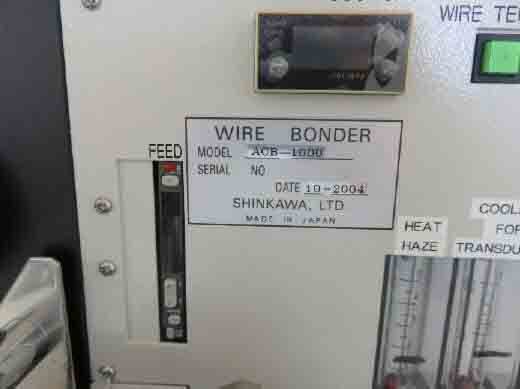

Used SHINKAWA ACB 1000 #9383143 for sale

URL successfully copied!

Tap to zoom

ID: 9383143

Vintage: 2004

Wire bonder

Target material

Variety: Small signal transistor, diode (loop frame type)

Width: 8-60 mm

Thickness: 0.07-0.3 mm

Wire: Gold wire, Φ 15 ~ 38 μm; Φ 20 ~ 50 μm; Φ 30 ~ 70 μm (2" flange pool used)

Bonding method: Au wire bonding by thermosonic bonding

Bond speed: 65 ms / 0.7mm wire

Wire length: 8 mm (Maximum)

Wire bend: Within 50 μm / wire length 2.0 mm

Bond area: X/Y = 66 mm (Camera offset)

Bonding accuracy: ± 3.5 μm (± 4.5 μm when using forming gas)

Load time: 3-150 ms (0.1 ms / Step)

Bond load: 30-2940mN (1 mN / Step)

Search speed: 1-80mm / s (0.1 mm / Step)

Bonding position setting: Self-teaching method

Work feeder section

Transport method: Digital pin feed method

Feed pitch: 71 mm (5 μm / Step)

Lead frame heating range: Room temperature to 350°C

Compressed air: 0.5 Mpa, 60 L / min

Vacuum: -74 kPa

Forming gas: 200 kPa 10 L / min

Power supply: Single phase, 100 VAC, 50/60 Hz

2004 vintage.

SHINKAWA ACB 1000 is an advanced heated automatic composite bonder designed for the fast operation of high-performance composite assemblies. This equipment can bond porous components together or bond metals, plastics, and ceramics in a single operation. SHINKAWA ACB-1000 is highly accurate and operates with low pressure to accurately bond components without damaging the material's structure. The system utilizes a full-featured servo control unit and flexible temperature control to evenly distribute thermal energy and consistently bond components. ACB 1000 comes with a modular build and advanced adjustable pneumatic pressure. This allows the machine to bond parts without the need for an excessive amount of energy and create perfect bonds between the parts without damaging or compromising the integrity of the material. It also has advanced vacuum control and nozzle flow control to minimise air bubbles and ensure that the bond is secure and consistent. ACB-1000 features a large work area and a flexible main arm with full 360-degree rotation to allow operators to accurately position and bond components. The tool also features a high-definition vision asset that is capable of detecting and positioning components with precision. SHINKAWA ACB 1000 is equipped with a unique operation sequence control model. This enables the equipment to complete several operations including positioning, heating, pressure application, cooling, and unloading of the assembled components. The control system can also track the operation parameters and data to ensure the accurate and repeatable bonding of each batch of components. SHINKAWA ACB-1000 is designed for reliable and intelligent bonding and is suitable for mass production composite assemblies. The unit meets the highest quality standards and is capable of bonding components which require sophisticated assembly processes. ACB 1000 is easy to install, use, and maintain. It is equipped with an intuitive graphical user interface with a menu-driven operation machine and an easily legible graphical display. This makes the machine easy to set up and use even for novice users.

There are no reviews yet