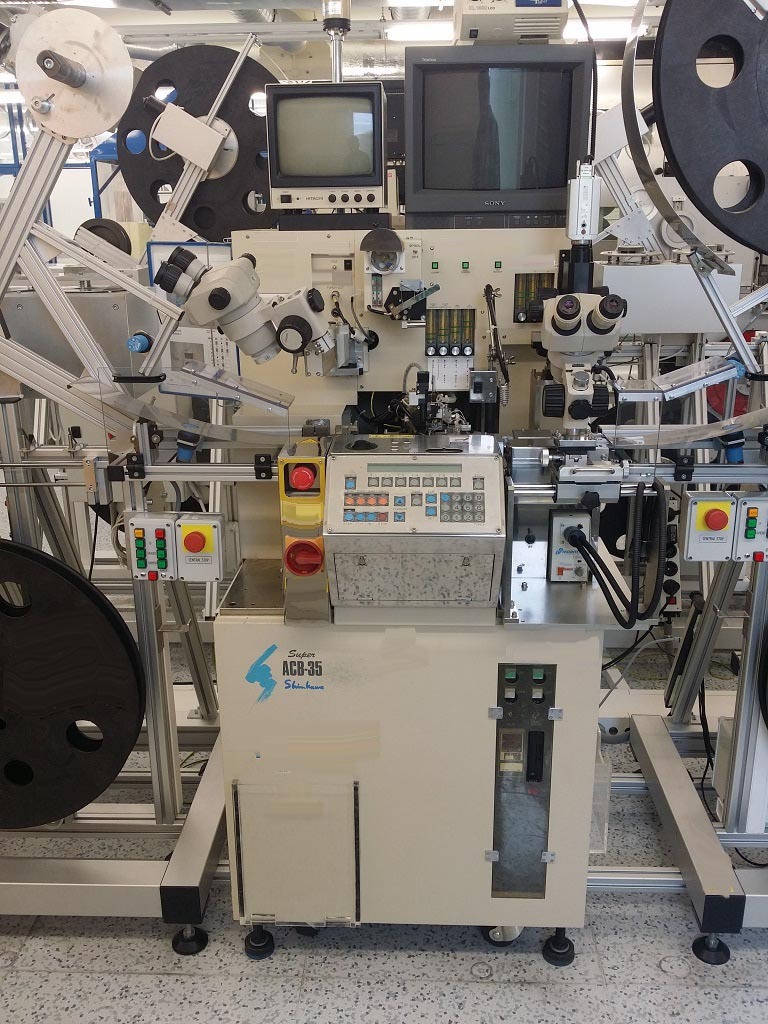

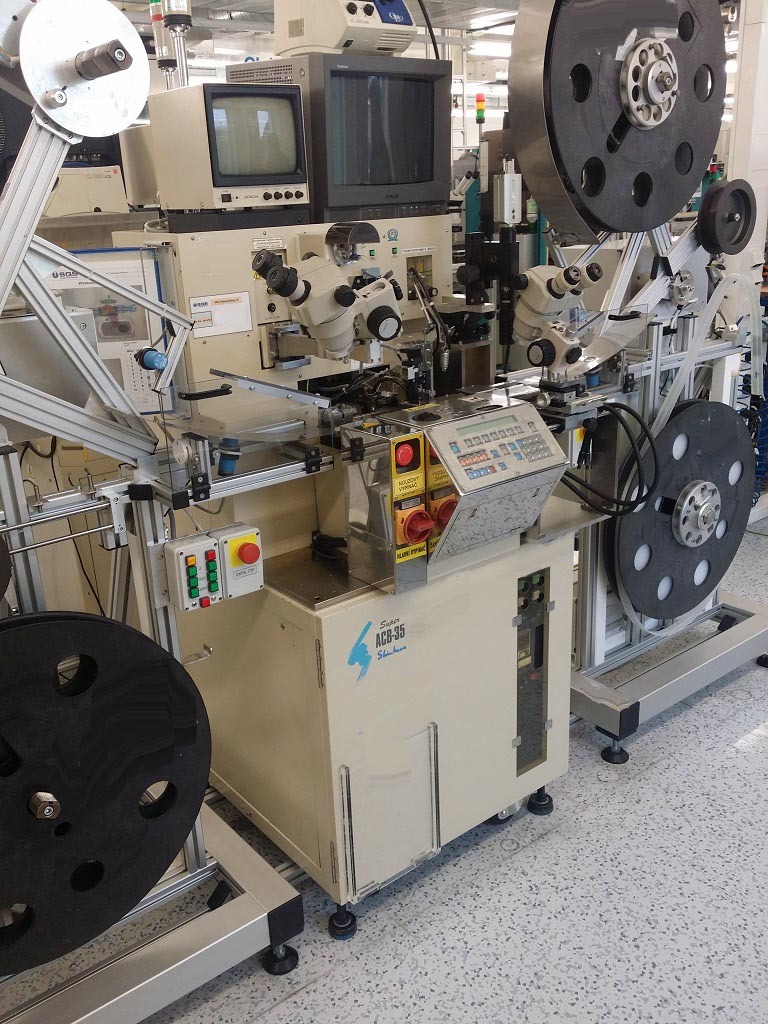

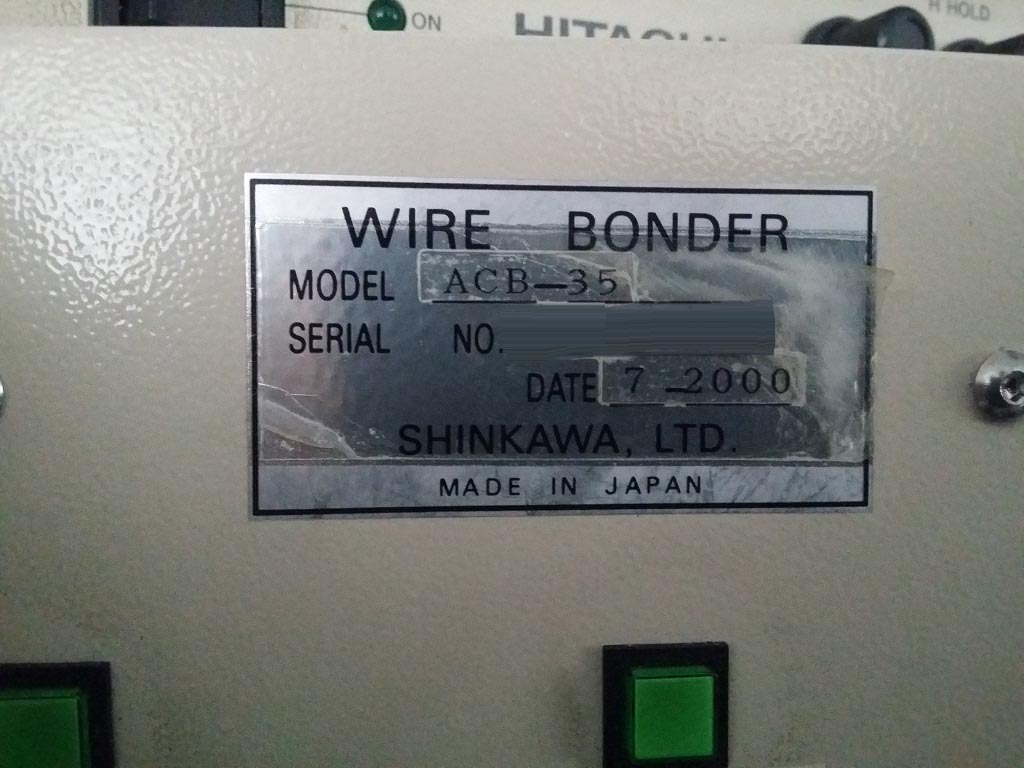

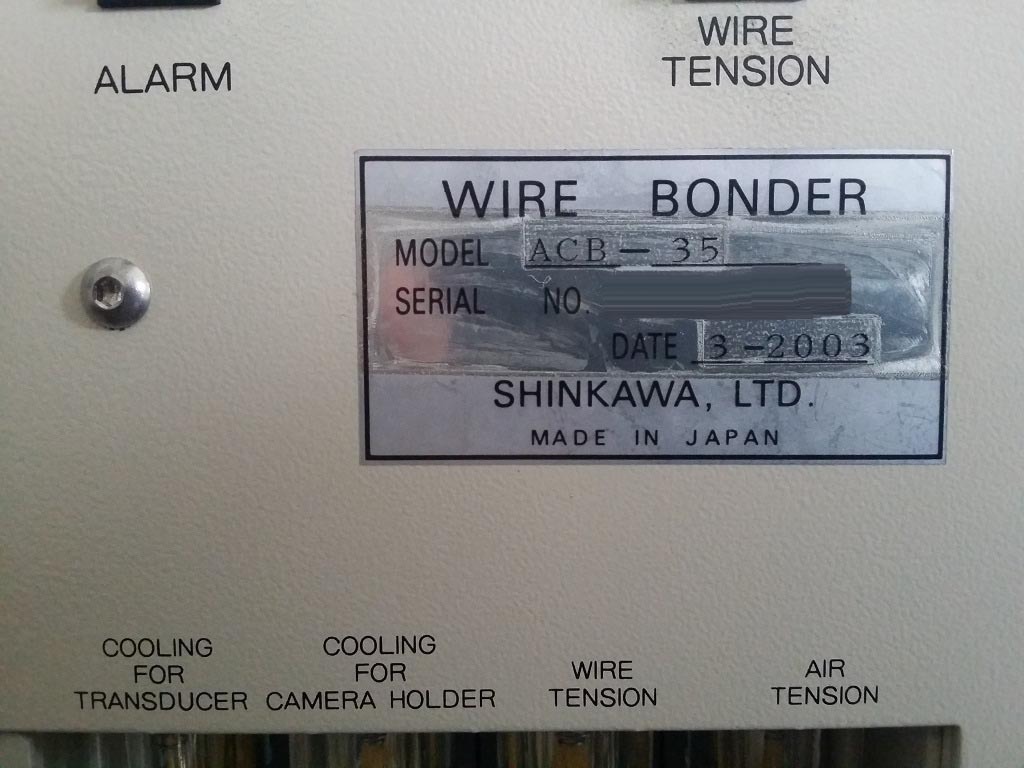

Used SHINKAWA ACB-35 #9142343 for sale

URL successfully copied!

Tap to zoom

ID: 9142343

Ball bonders

Bonding method: Thermosonic bonding

Machine accuracy: ±5µM

Bonding speed: 0.120s / 1 mm Wire

Bonding wire length: Maximum 7 mm

Bonding temperature: Maximum 250°C

Pattern recognition system:

Recognition method: Gray-scale correlation system (256 Scales)

Recognition time: Within 0.2s / 2-Point alignment

Recognition range:

X: ±0.55 mm

Y: ±0.39 mm

Automatic pad / Lead centering capability

Bonding area:

Wire size:

X: 60 mm

Y: 30 mm

Bonding wires: Gold wire 23~38 micro meter

Program storage capacity: Maximum 20 wires

Lead frame:

Width: 8~30 mm

Length: ~95 mm

Thickness:

0.1~0.3 mm (Strip type lead frame)

0.1 -0.2 mm (Hooped type lead frame)

Option: Host computer interface SECS l / SECS II

Utilities:

Input power: AC 100 V ±5%, 50/60 Hz

Power consumption: 900 W (1400 Watts for (2) Heaters)

Compressed air: 300 kPa (3kgf / cm²) 20 C/min

Vacuum: Below -200 kPa (-2 kgf/cm) 10 Q/min

2000-2003 vintage.

SHINKAWA ACB-35 is a highly efficient and reliable automatic wire bonder that offers unparalleled control and precision for the bonding process. ACB-35 utilizes advanced technology to ensure accurate transfers of energy, current, and materials that helps enable strong, dependable wire bonds. The machine offers a range of options and features that provide users with the versatility to create high-quality wire bonds at an optimal speed. SHINKAWA ACB-35 is equipped with a selectively programmable force arm that allows for the accurate adjustment of bonding force settings. This provides control of the wire bonding process to users. The equipment also features a dual-vibration energy system which applies two different frequencies of vibration energy to accurately control the mass force of the bonding force. The machine has a large capacity wetting head which allows for fast and accurate wire bond formation. The wetting head contains a nozzle that has an optimized design to ensure accurate wire patterning. It also features a temperature sensor to monitor the temperature of the bonding wire which helps to prevent wire fragmenting due to thermal stress. ACB-35's high-capacity wire reel allows for efficient and accurate single-piece transfer of wire onto the bonder. It can also handle wires of different thickness and material types. An auto-reeling unit helps reduce reel changes, allowing users to complete the bonding process more quickly. SHINKAWA ACB-35's user-friendly interface allows users to manage and control the entire bonding process quickly and easily. It also has a 7" touchscreen that provides enhanced viewing capability and user-friendly menu options. The machine also offers multiple options for monitoring and troubleshooting the bonding process, such as an error log and diagnosis machine. Overall, ACB-35 is a reliable and efficient automatic wire bonder that is suitable for a variety of bonding applications. It offers numerous features and options that allow users to optimize the bonding process for their specific needs. As a result, SHINKAWA ACB-35 is an ideal machine for users who require reliable and efficient bonders.

There are no reviews yet