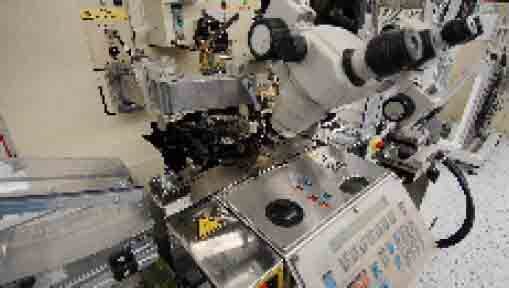

Used SHINKAWA ACB-35 #9315287 for sale

URL successfully copied!

Tap to zoom

ID: 9315287

Vintage: 2000

Ball bonder

Bonding method: Thermosonic bonding

Machine accuracy: ±5µM

Bonding speed: 0.120s / 1 mm Wire

Bonding wire length: Maximum 7 mm

Bonding temperature: Maximum 250°C

Pattern recognition system:

Recognition method: Gray-scale correlation system (256 Scales)

Recognition time: Within 0.2s / 2-Point alignment

Recognition range:

X: ±0.55 mm

Y: ±0.39 mm

Automatic pad / Lead centering capability

Bonding area:

Wire size:

X: 60 mm

Y: 30 mm

Bonding wires: Gold wire 23~38 micro meter

Program storage capacity: Maximum 20 wires

Lead frame:

Width: 8~30 mm

Length: ~95 mm

Thickness:

0.1~0.3 mm (Strip type lead frame)

0.1 -0.2 mm (Hooped type lead frame)

Option: Host computer interface SECS l / SECS II

Utilities:

Input power: AC 100 V ±5%, 50/60 Hz

Power consumption: 900 W (1400 Watts for (2) Heaters)

Compressed air: 300 kPa (3kgf / cm²) 20 C/min

Vacuum: Below -200 kPa (-2 kgf/cm) 10 Q/min

2000 vintage.

SHINKAWA ACB-35 is a piece of specialized equipment designed to make thejoining process of wires and cables simpler and more efficient for manufacturing professionals. It utilizes a combination of an adjustable clamp arm and precision cutting blade to provide a reliable wire bonding service. The clamp arm adjusts to accommodate multiple sizes and shapes of wire or cable, allowing users to position the wire in an optimal bonding position without wasting time or energy in making manual adjustments. The arm also holds the wire in place while it is being cut, eliminating unnecessary movement that could cause damage to the wire or incorrect measurements. Once the clamp arm is adjusted, the cutting blade is engaged. It is composed of a high-grade stainless steel that is designed specifically for cutting wires and cables with accuracy and precision. It is adjustable for part of the cutting to be done at a high speed, while other parts are left to be cut at a slower speed. By doing this, the blade is able to cut all parts of the wire accurately and with minimal fraying or warping. The blade is integrated with a built-in infrared laser guide to help users line up and position the blade correctly. The laser lines up with the clamps and near the blade to provide a visual guide for the user. ACB-35 makes the bonding process simple, reliable and efficient, and is ideal for use in large-scale manufacturing settings or for individual producers. The cutting blade is a precision tool designed specifically for cutting wires and cables with accuracy and minimal risk of fraying or warping. The adjustable clamp arm and integrated laser guide make the bonding process fast and straightforward, eliminating tedious manual adjustments. SHINKAWA ACB-35 is a reliable and efficient bonding tool that is perfect for any wire or cable bonding job.

There are no reviews yet