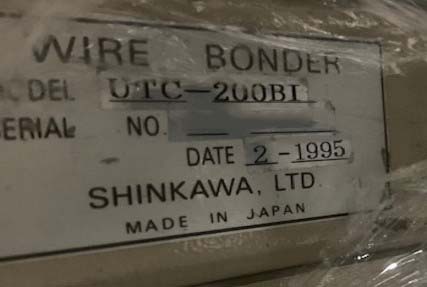

Used SHINKAWA UTC-200 BI #293639586 for sale

URL successfully copied!

Tap to zoom

SHINKAWA UTC-200 BI is an ultra precision and ultra thin bonder designed for the dicing, bonding and packaging of semiconductor devices. It is capable of creating high quality and reliable bonds with a run-to-run consistency that are required for semiconductor and related industries. This precision machine has been specifically designed for high-end volume production of ultra thin chips, such as FETs, SOI and thin-film transistors. The Bonding tool is a highly sophisticated equipment that provides accurate and repeatable die-bonding and packaging capabilities. SHINKAWA UTC-200BI bonder is composed of several components. The bonder includes a heating module, chuck, detect system, degas chamber, monitor and a die holder. The heating module is equipped with an Infrared Heater, a Quartz Flash Lamp and an Aluminum Heater. All these components have been optimized to provide extremely precise temperature control and an accurate distal temperature profile. The two chucks can be quickly adjusted to match the size of the chip and provide a strong hold during the bonding process. The bonder uses a detection unit to automatically detect the shape and size of the die before bonding. The detect machine also provides feedback for fine-tuning the process for optimal results. The monitor and the die holder are designed to keep track of the process and allow for the adjustments of bond lines according to the type of chip. UTC 200 BI also provides degas capabilities which make it flexible to use for various types of applications. The degas process is conducted in an enclosed chamber that is capable of reaching atmospheric pressure levels which are beneficial for the bonding of sensitive dies. UTC-200 BI Bonder is an ideal tool for high-volume device fabrication. Its precision and repeatability features ensure that chip bonding and package operations are performed with the highest quality. Its advanced detection tool provides accurate information on alle size and shape of the die as well as feedback for fine-tuning the process for optimal results. Finally, the degas process makes it suitable for various types of applications.

There are no reviews yet