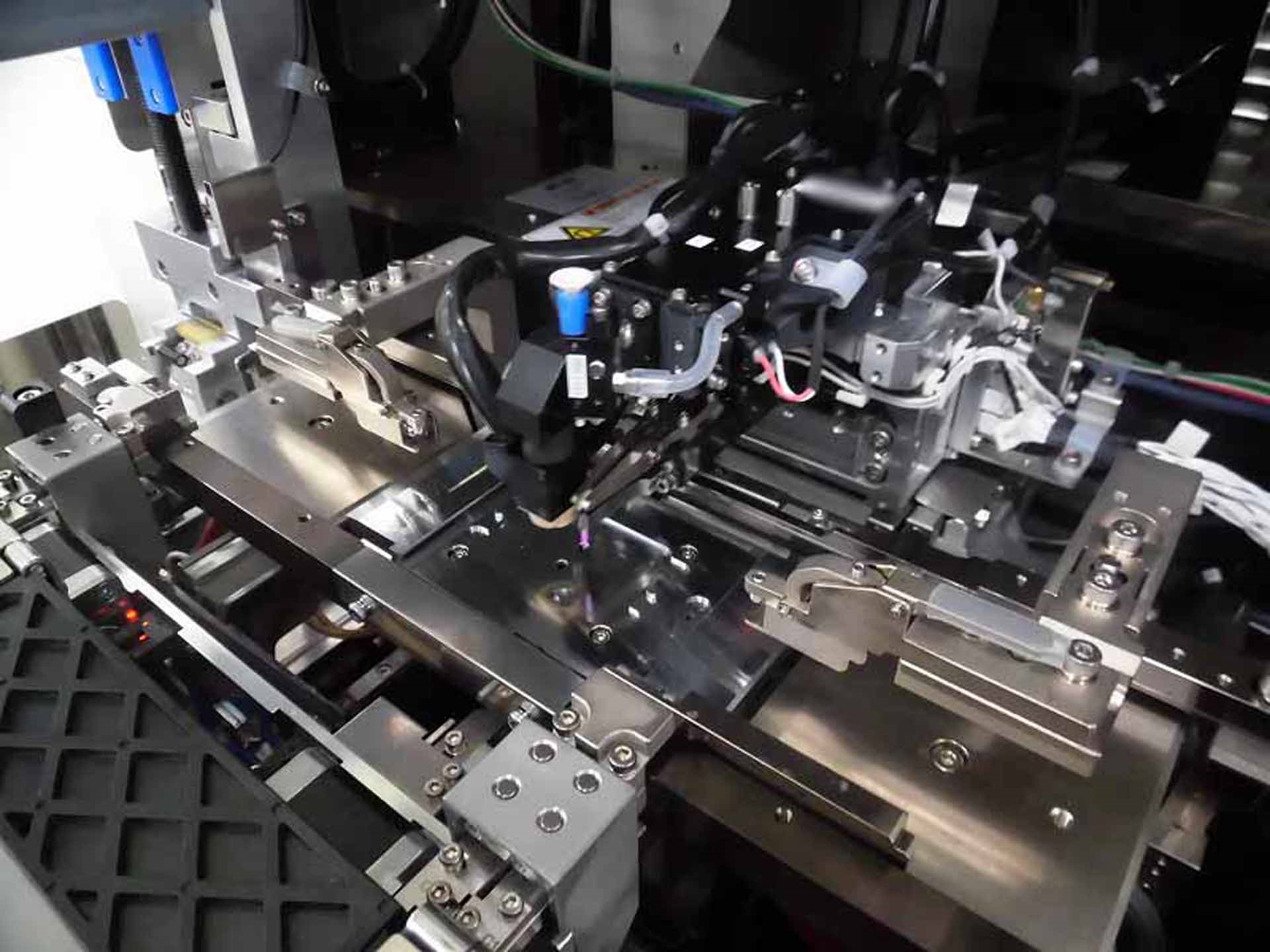

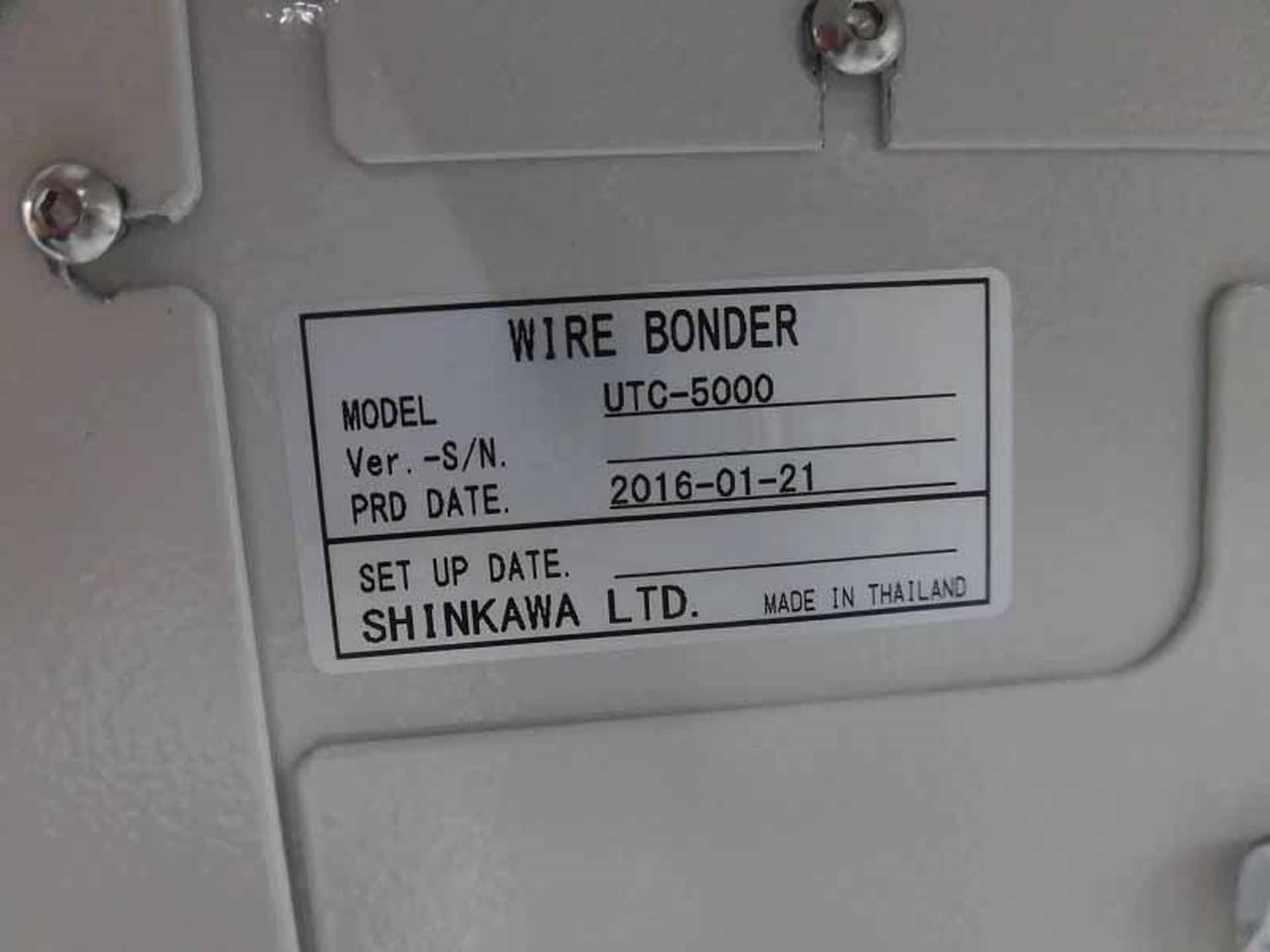

Used SHINKAWA UTC-5000 #9261680 for sale

URL successfully copied!

Tap to zoom

SHINKAWA UTC-5000 bonder is a high-performance automated bonding module built with advanced components. It's an all-in-one tool for packaging that uses micro technology to accurately bond components. SHINKAWA UTC 5000 utilises advanced recognition technology to precisely and quickly identify correct parts and apply the correct amount of bond to each part of the device. The bonder is designed with a 9-axis robot that provides patients the highest accuracy in a controlled, ergonomic environment. The multi-axis arm of UTC-5000 enables it to be customised to the user's preferences such as adjusting the range of motion or controlling the RPM speed applied during the process. This allows for maximum efficiency when working with different types of assemblies such as circuit boards, ceramic substrates and rigid flexes. It's able to achieve unprecedented accuracy through thorough scans of the parts being bonded that help eliminate lamination errors and material flips. The onboard camera vision system is also used to verify the presence of parts and accurately follow quality control guidelines. The bonder is able to handle both fine-pitch and ultra-fine-pitch components. It has the capability to bond not only single-layer components but also double-layer ones. The ambidextrous tweezer that is included provides a much larger area of contact, enabling a stronger bond.It also includes an ultra low-volume air nozzle for increased precision when dispensing glue and other materials. UTC 5000 also has a highly flexible and intuitive software which can be up-and-running in a matter of minutes. It lets users: i. Set up and save multiple jobs. ii. Make changes quickly and easily. iii. Monitor the bonding progress. iv. Identify discrepancies quickly. v. Read error codes for immediate resolution. SHINKAWA UTC-5000 bonder is a highly reliable and accurate machine that is well-suited for many modern applications. It offers unparalleled accuracy even in the most challenging processes and helps manufacturers reduce errors and save time on production. This machine provides manufacturers the utmost cost savings and increased yield rates due to its efficient design and tailored components. With SHINKAWA UTC 5000, it is easier to adhere to quality control guidelines and increase product reliability.

There are no reviews yet