Used SHINKAWA UTC-5000 #9261683 for sale

URL successfully copied!

Tap to zoom

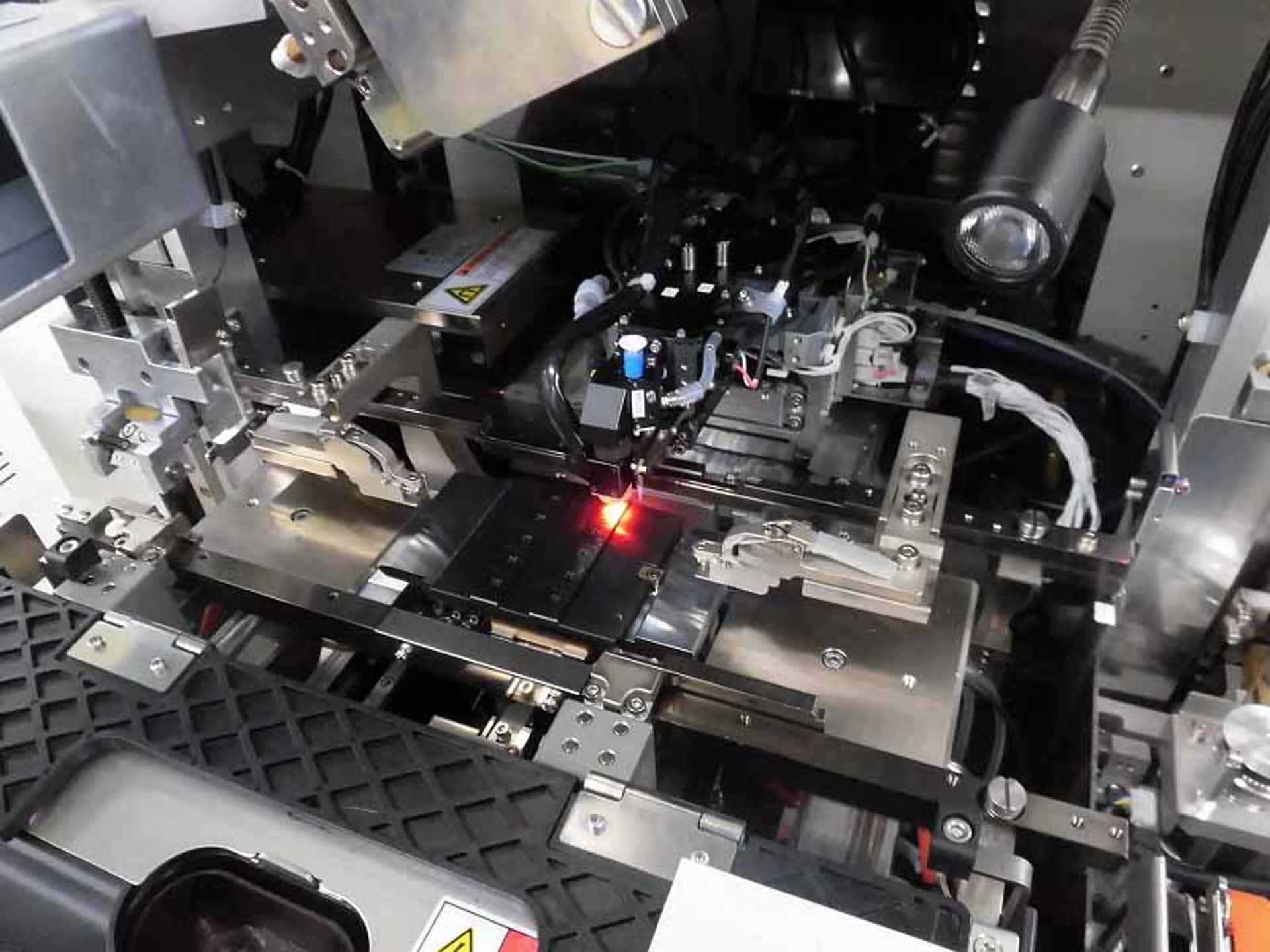

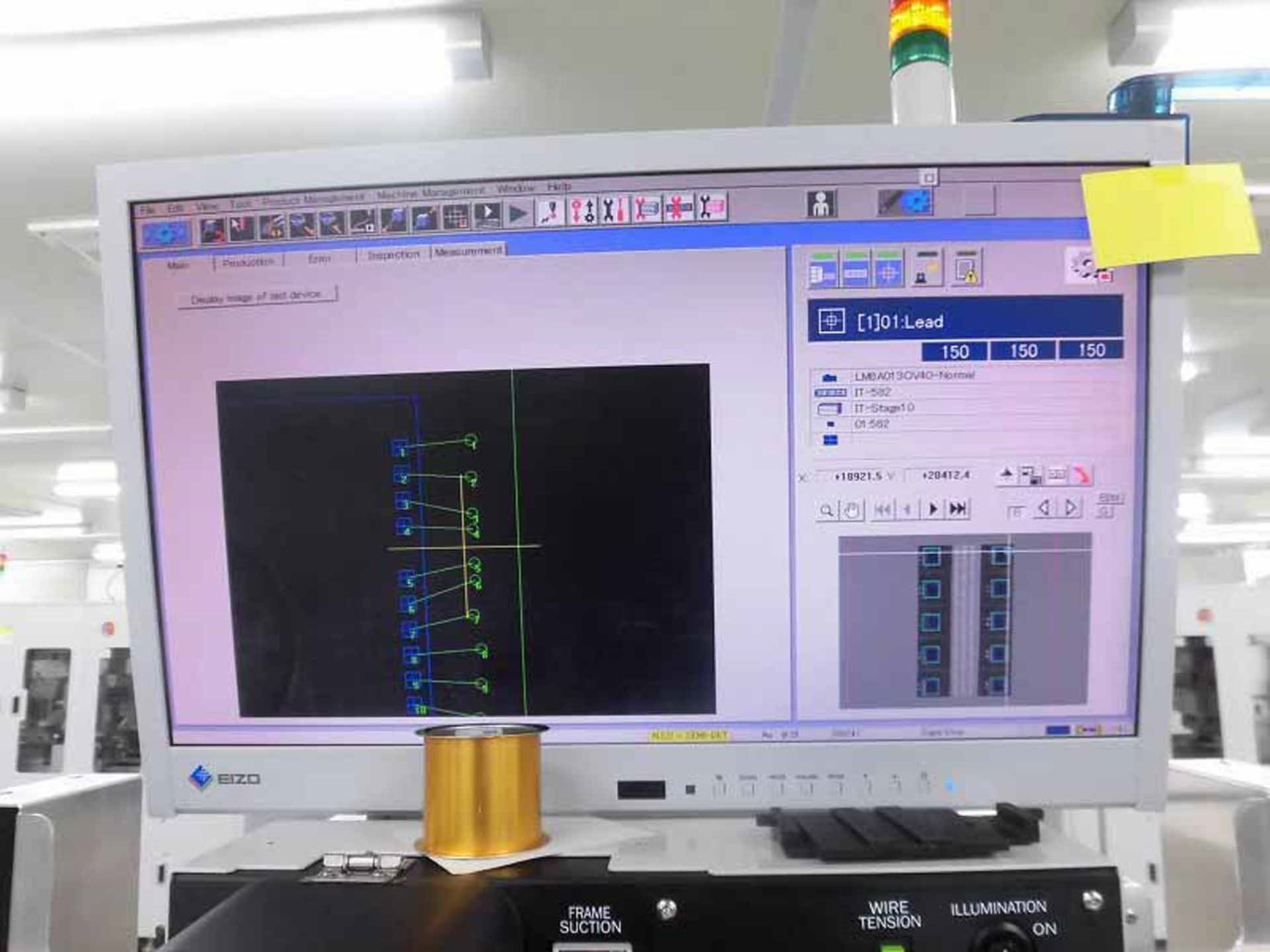

SHINKAWA UTC-5000 is an automated wire bonder designed for automated electrical interconnections on electronic devices. It is utilized for high-density surface mounting applications. SHINKAWA UTC 5000 features a highly precise and versatile equipment and utilizes advanced bonding technologies, resulting in a high degree of productivity and reliability. The major components of UTC-5000 include a wire supply system, bond head, wafer handling systems, main body and power supply. The wire supply unit is responsible for the delivery of wire thermocouples to the bond head. It makes use of a vacuum machine to pick up the thermocouples and transfer them to the bond head for bonding. The bond head is equipped with a special thermocouple punching operation, which accurately lays down the wires onto the device's substrate. The wafer handling tool is responsible for positioning the wafers and setting the correct alignment of the thermocouples. The main body of UTC 5000 contains the bonded and programmed electrical features. It is the core of the machine, which controls its movements and monitors the time cycle. The control asset helps in monitoring the operations and also helps to store the bond programs. SHINKAWA UTC-5000 is powered by a universal industrial power supply. It receives the power from an three-phase AC supply and supplies the power to the main body and other components of the machine. SHINKAWA UTC 5000 is capable of carrying out a variety of electrical interconnections on different devices. It is capable of performing wire bond, turning, lid opening and hole drilling operations. The machine features a wide range of bond techniques, such as ball, wedge and ribbon bonding. The machine also has an automatic wire drift compensation model, which allows for a precise and continuous wire feed rate, even under variations in the wire tension. UTC-5000 is a highly reliable and space saving equipment. It is equipped with an advanced bond inspection system, which ensures that all the connections are error-free. The bond monitoring unit also allows for the generation of detailed inspection reports, which provide information about the integrity of the connections. The machine also features an intuitive user-friendly interface, which makes it easy to use and program operations.

There are no reviews yet