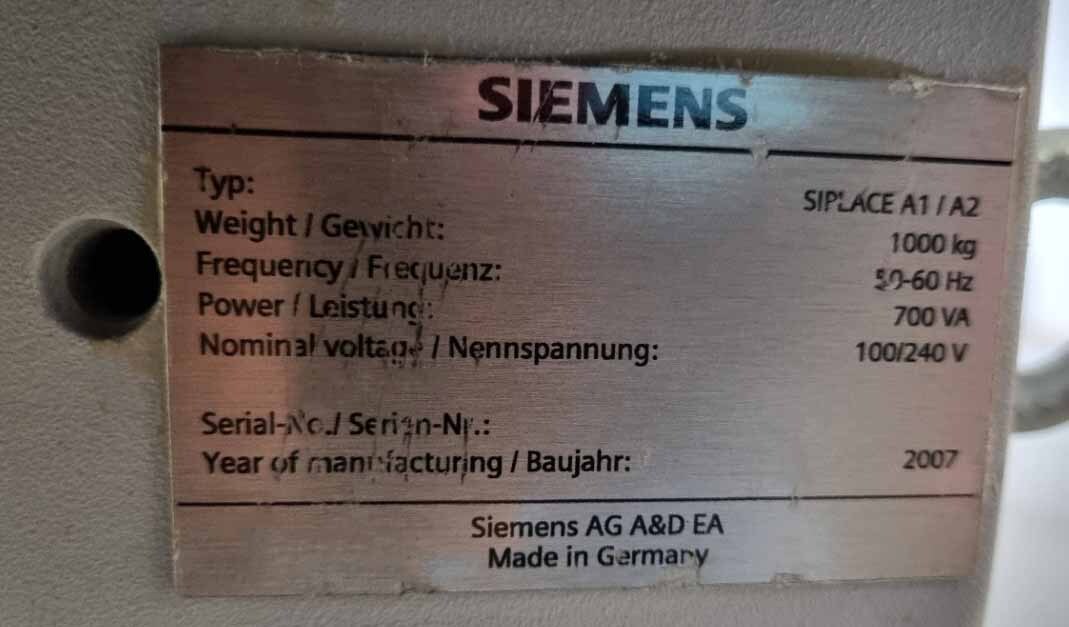

Used SIEMENS Siplace A2 #293610782 for sale

URL successfully copied!

Tap to zoom

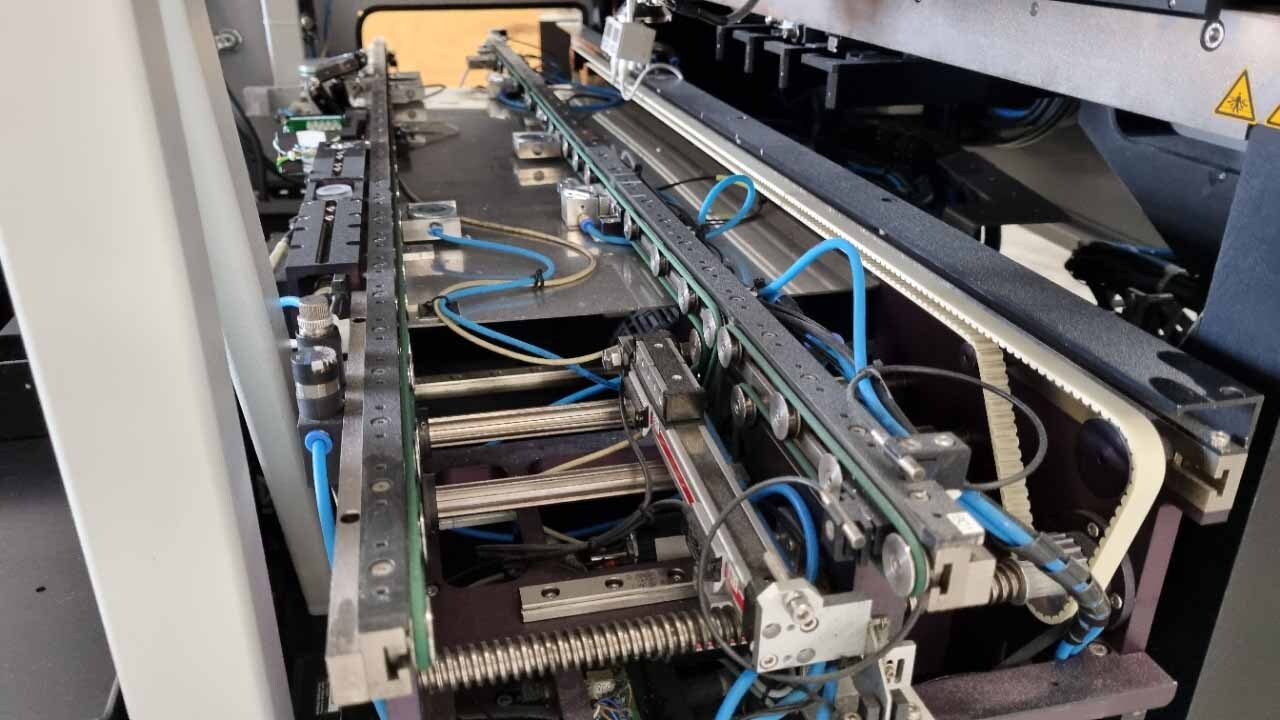

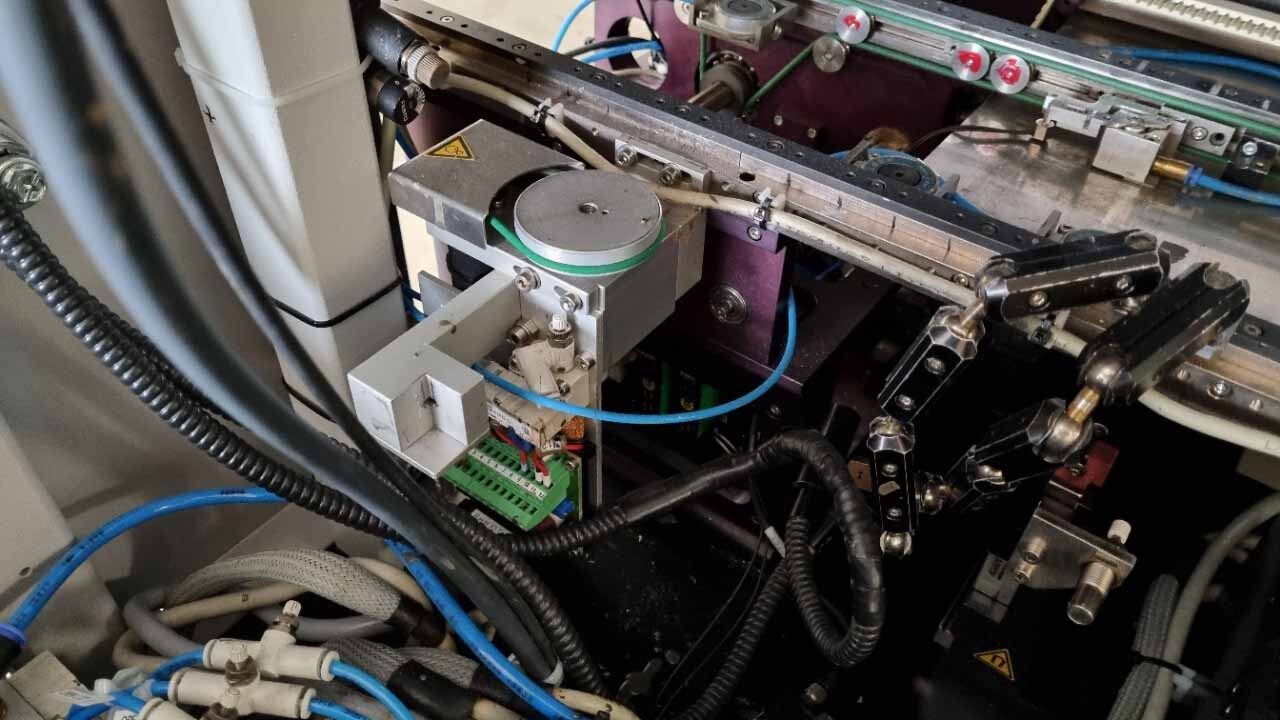

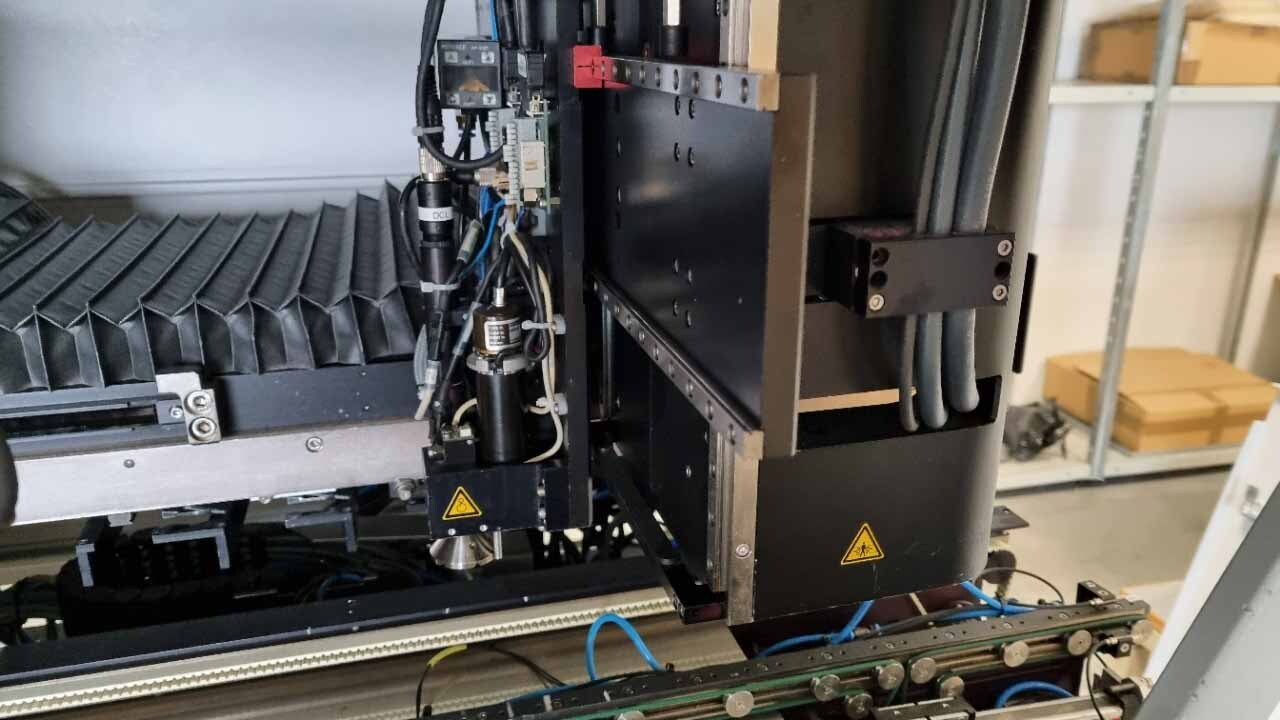

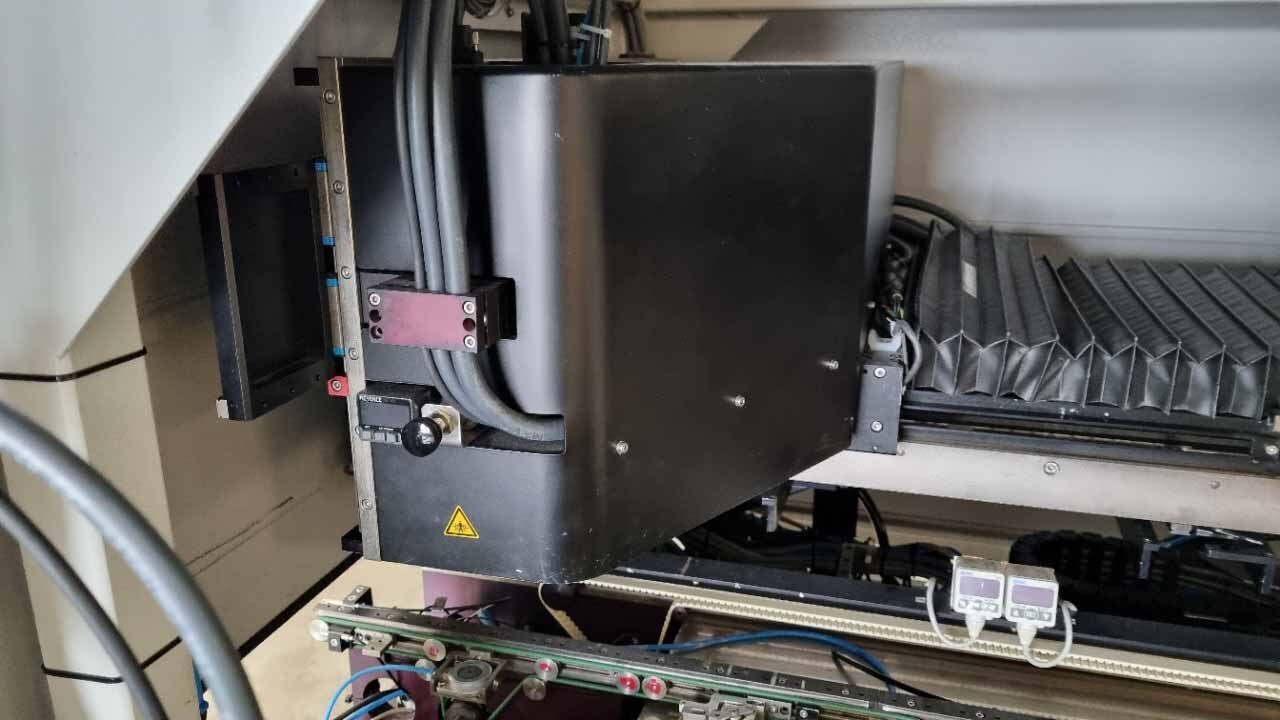

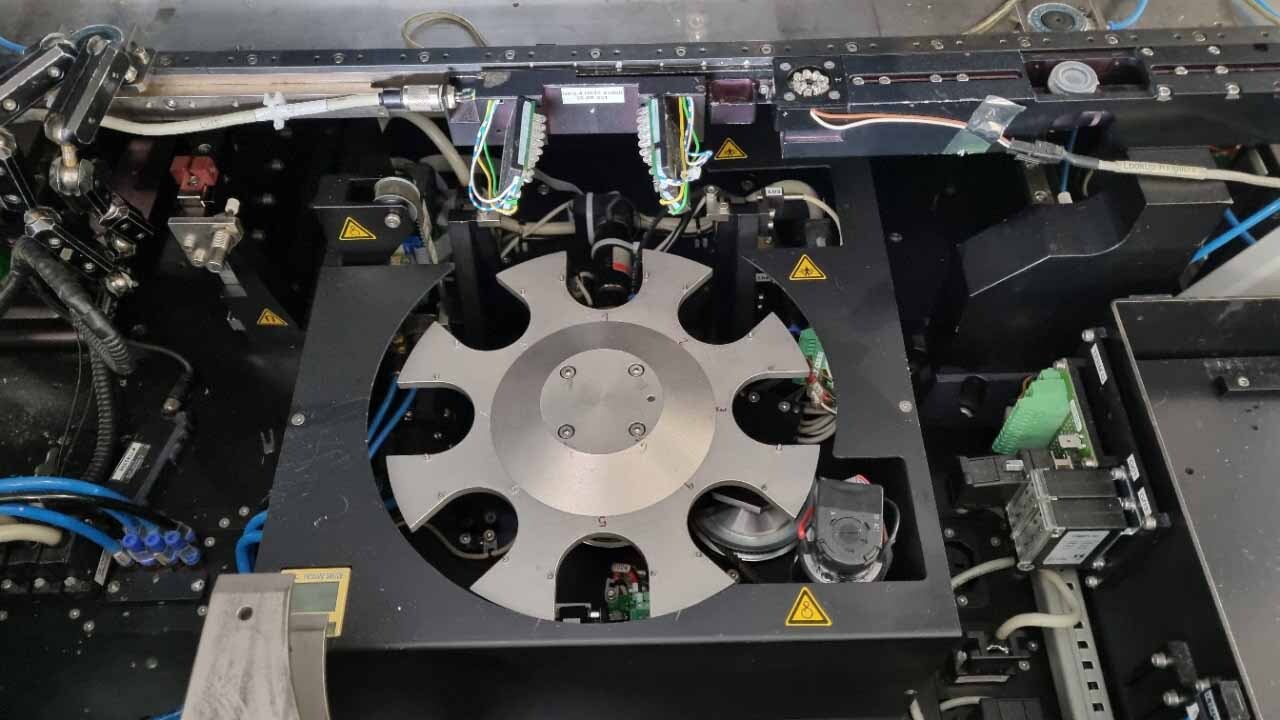

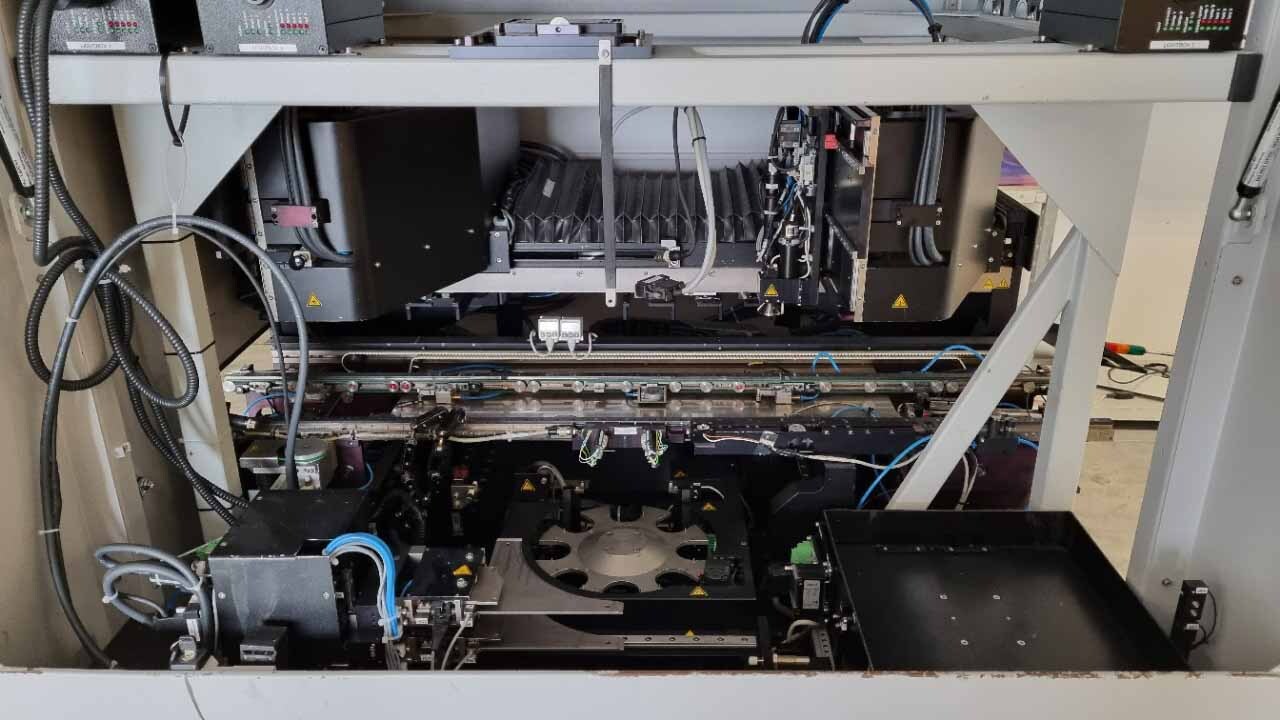

SIEMENS Siplace A2 is a high-performance bonder designed for the integration of components in the automotive, medical, and industrial electronics sectors. This sophisticated and reliable machine features advanced technologies including a bonded micro-electronics precision platform and an integrated A2 adapter, allowing for fast and efficient automated production. Siplace A2 features a wide variety of automated technology features. For example, the system can accommodate field configurations of up to 12 heads, enabling high-speed production of solder joints with increased reliability. The machine also provides an intuitive operator interface, enabling easy operation and monitoring. Furthermore, it incorporates a mini rail system for easy and quick maintenance. SIEMENS Siplace A2 works with advanced jetting technology that can accurately and reliably deliver solder paste to the board surface quickly. It is equipped with a dynamic jetting head that ensures low-deposit solder paste and avoids solder bridges. The machine also uses advanced reflow-tuning software with powerful algorithms for efficient heating control that produces reliable and high-quality soldering. Additionally, with the built-in material flow-control system, Siplace A2 can ensure a safe, efficient and cost-effective sales process. SIEMENS Siplace A2 is capable of accurately placing and soldering components through the use of the latest laser-guided assembly technology. This technology provides accuracy of up to 0.2mm, making it ideal for the high precision nature of microelectronics components. The machine also supports 4-point placement and down-speed soldering to ensure full control over the process. Siplace A2 is designed to be as cost-effective as possible due to its automated processes and high-quality accuracy. This machine is capable of making anywhere from 12,000 to 23,000 components per hour, making it suitable for high-volume production lines. It is also quick and easy to set up, reducing downtime and defect risks. The combination of its advanced automation and sophisticated technologies provide reliable, cost-effective and efficient production.

There are no reviews yet