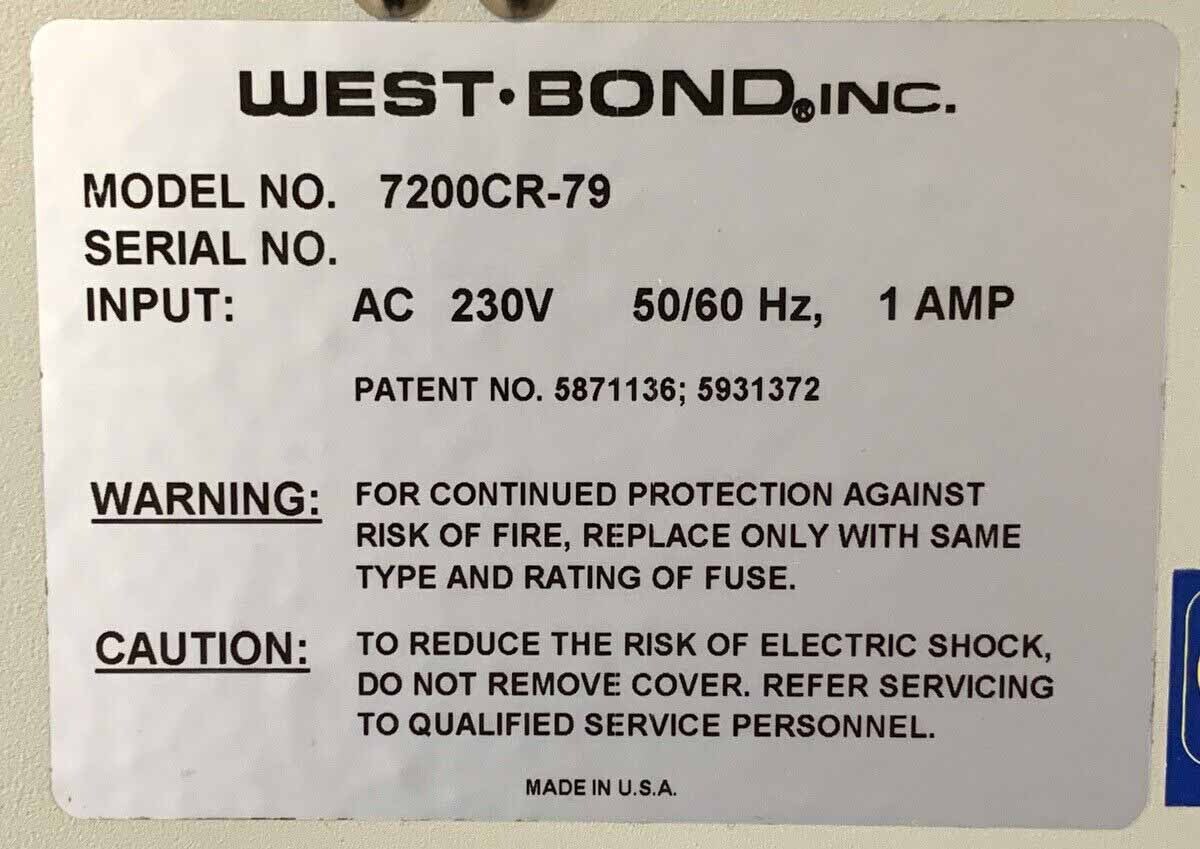

Used WESTBOND 7200CR #293639980 for sale

URL successfully copied!

Tap to zoom

WESTBOND 7200CR is an automated ball bonder designed to provide efficient production of complex microelectronic assemblies. The high-precision, high-speed equipment includes a 300mm wafer-level manipulator to handle precision positioning of wafers and components, as well as two separate robotic arms. The two arms enable both ball bonding and wedge bonding capabilities. The standard ball bonder has an adjustable atmosphere chamber that maintains consistent nitrogen pressure and humidity to minimize surface defects, while the wedge bonder is designed to facilitate quick bonding of high aspect ratio wires and gold dust welding. WESTBOND 7200 CR uses an integrated vision system to identify and align components with precision. The vision unit also allows the machine to monitor wire positioning and ball size. Using precision axial, radial, and height alignments, 7200CR is able to achieve accurate, repeatable connections even in environments contaminated with dust. The machine includes a radiometric sensor to detect the presence of contaminations on the bonder. SmartBonder technology has been incorporated into 7200 CR, providing users with improved reliability, total process control and maximum process yield. The tool can be configured with an on-board feedback loop for adjustment of parameters such as temperature, ball size, and gap size in real-time. The asset also includes an automated wire count verification feature to ensure data integrity. WESTBOND 7200CR offers a range of integrated component sensors to ensure fail-safe performance. Advanced process monitoring capabilities are provided through the machine's in-built monitoring & control model, which records each process cycle in real-time. The advanced software design of WESTBOND 7200 CR enables it to be used as part of a fully automated production equipment. The system can be integrated with automated feeders, component handling systems, and other peripheral devices. The open architecture also makes it easy to incorporate new functions, processes and features. The well-designed ergonomic operator interface enables operators to monitor the machine's performance and make adjustments with ease. The user friendly interface is designed to help reduce training times and User error. 7200CR is a versatile, reliable and high-performing automated bonder. Its range of features ensure consistent performance and maximum process yield for sophisticated microelectronic assemblies.

There are no reviews yet