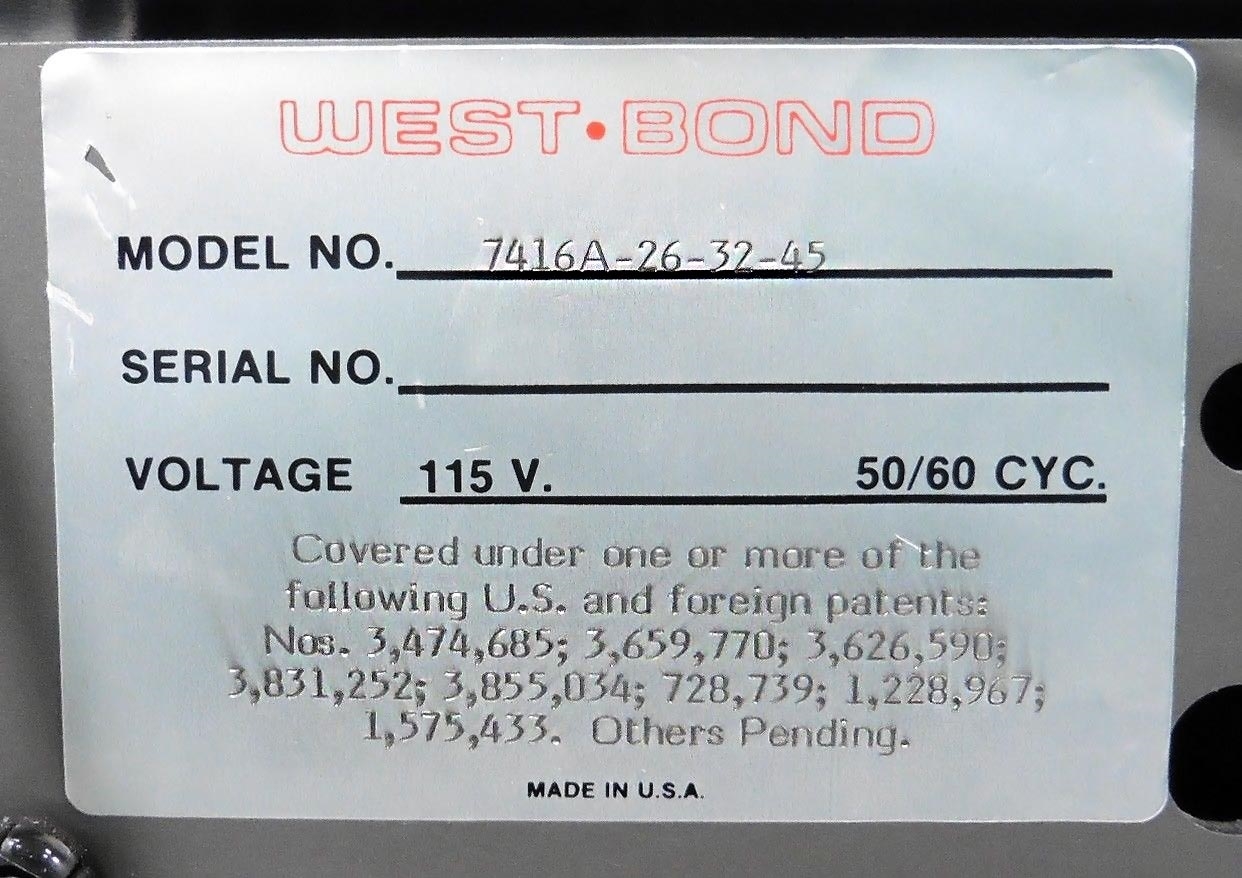

Used WESTBOND 7400A #9239006 for sale

URL successfully copied!

Tap to zoom

ID: 9239006

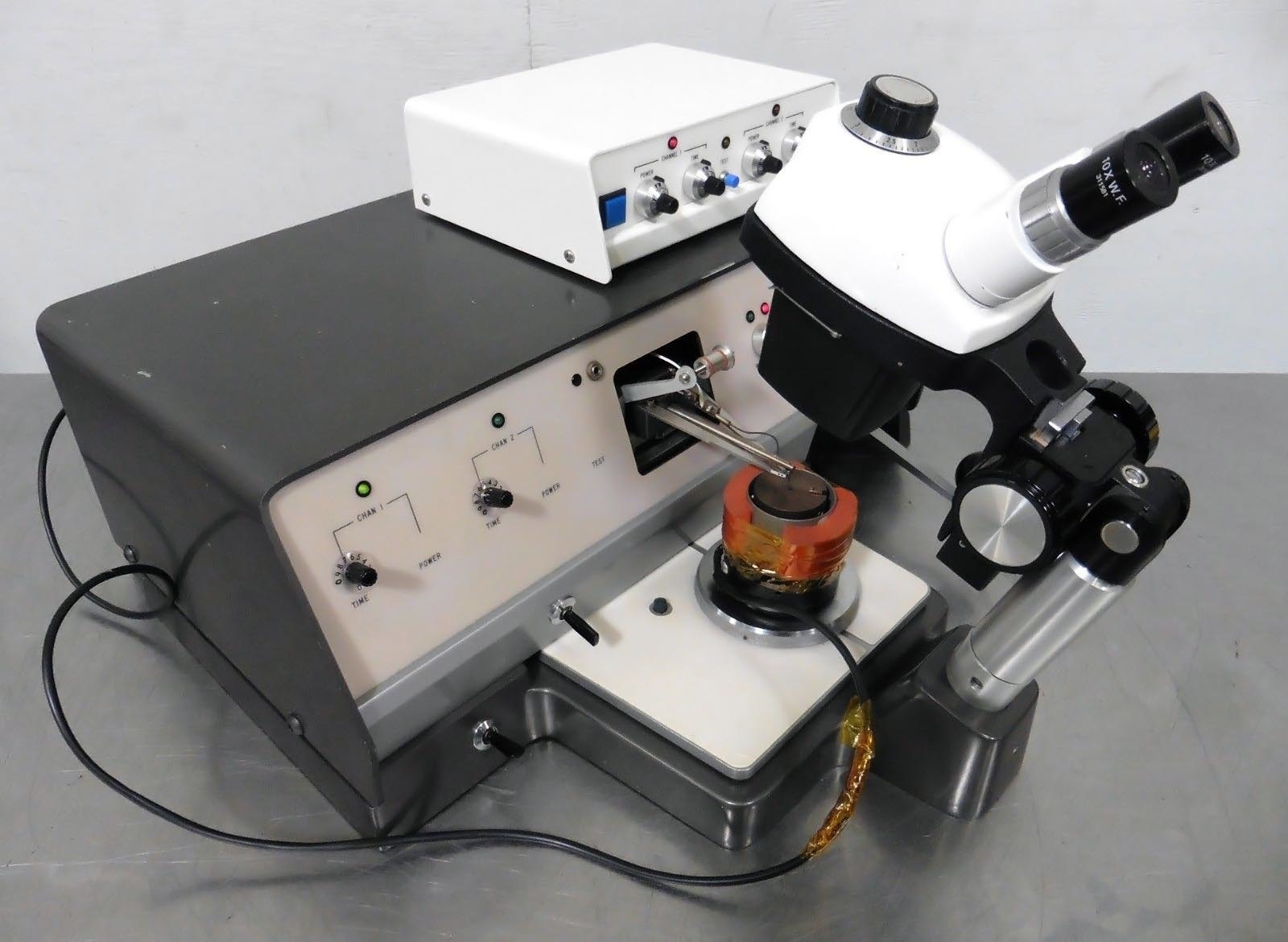

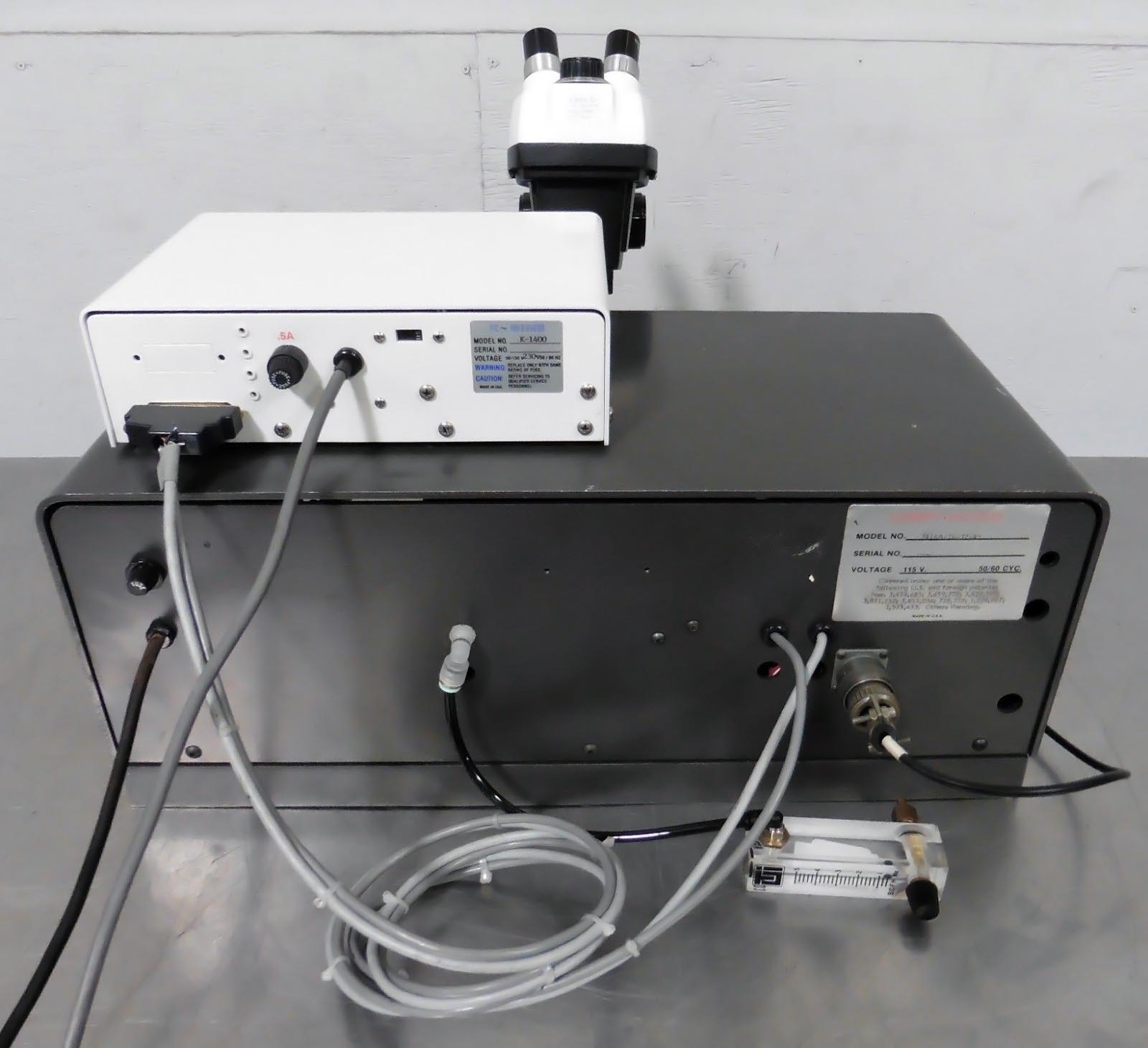

Ultrasonic manual wedge wire bonder

Ultrasonic generator

BAUSCH & LOMB Stereo zoom 4 microscope

Eyepieces: 10x

Heated workholder

With temperature controller.

WESTBOND 7400A is a high-precision wire bonder that is designed to connect electrical components to circuit boards. This equipment is used in electronics applications, such as in the manufacturing of semiconductor devices, LED modules, and medical implants. WESTBOND 7400 A uses a tightly coupled lens system, which offers a high-definition bonding image and allows for precise hand-eye coordination. A fully customizable vision unit is also incorporated into the bonder, allowing for easy recognition of different bond patterns. The machine has automated wire feeding capabilities and a pressure-controlled servo actuation tool, which increase the accuracy and speed of the bonding process. 7400A has the capacity to work with a variety of wire types, including aluminum, copper and gold. Its wire positioning capability offers great accuracy and repeatability during the wire looping process, while its wire loop forming asset provides high quality and uniform bonding for a variety of applications. The model has a high-speed bonding process, which can achieve up to 30 bond heads per second. The bonder also includes Pb-free and low-temperature bonding capability for sensitive and high-reliability applications. The equipment includes four servo-controlled loops with a wide variety of loop sizes, shapes and positions, which can be accurately set and easily adjusted with the use of a touch-screen interface. 7400 A is equipped with advanced data logging and memory features. This includes the ability to store up to 16 bonding programs for easy recall. This system can also be used for diagnostics and troubleshooting, which can help reduce downtime and increase efficiency. WESTBOND 7400A is an advanced and reliable wire bonder that offers great accuracy and repeatability for a variety of electronics applications. The combination of the high-precision camera unit, automated wire feeding, and pressure-controlled servo actuation machine allows for accurate and efficient bonding of wires. It is a reliable tool that processors of all experience levels can rely on for precision bonding jobs.

There are no reviews yet