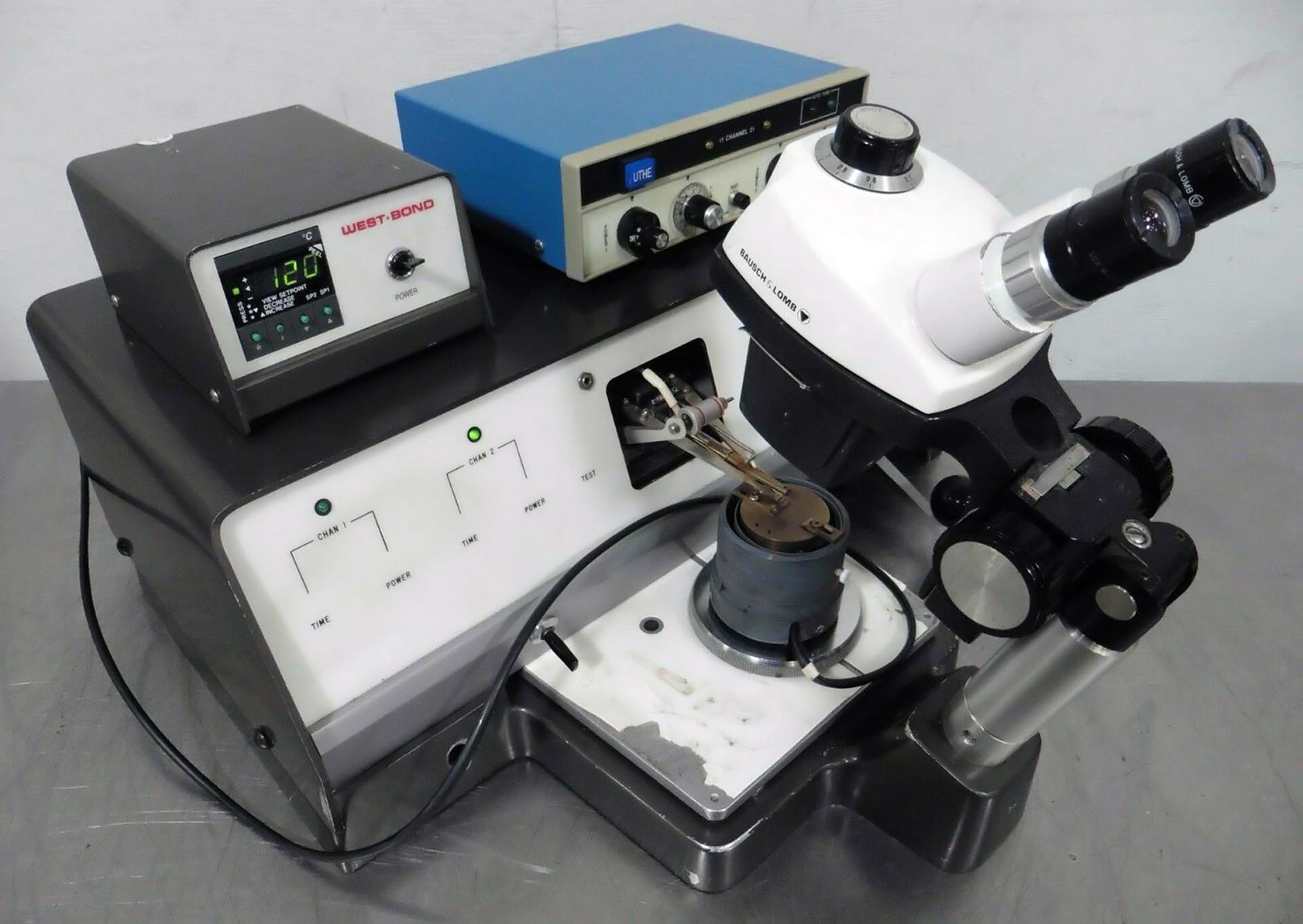

Used WESTBOND 7400A #9239009 for sale

URL successfully copied!

Tap to zoom

ID: 9239009

Ultrasonic manual wedge wire bonder

Feed: 45°

Aluminum / Gold wires ranging from: 0.0007" to 0.002"

Ultrasonic generator

BAUSCH & LOMB Stereo zoom 4 microscope

Eyepieces: 10x

Heated work holder

With temperature controller.

WESTBOND 7400A is an automatic wire bonder designed for use in the wire bonding process of making semiconductor products. It can be used to bond an array of fine wires or terminals, which are placed on leads, pads and other components of semiconductor devices. WESTBOND 7400 A is used to pass electric current through the wire in order to connect various parts together. 7400A is designed to be used in a high-temperature, high-pressure environment. This device is capable of thermal and barometric testing and can withstand very high temperatures up to 482F (250C). 7400 A Bonding System consists of a heated baseplate, a programmable programmable bonder and a specialized wire feeder. The heated base plate ensures the bonder of uniform temperature in the bonding process. The bonder is provided with programmable bonding parameters, which can be easily adjusted in order to perform the bonding procedure as required. The programmable bonder ensures the bonding parameters can be fine tuned as required. With WESTBOND 7400A the operator can select different types of material for the wire, its size and the desired electricity parameters of the bond. WESTBOND 7400 A boasts a range of features that enable superior performance. It has automatic wire cutting technology, enabling precise bond lengths. 7400A is capable of making extremely small wires, as it is capable of bonding up to 0.001 inch diameter wires. This bonder is also capable of making the full range of difficult joints, such as anisotropy, angled, Y-bonds or both. 7400 A also allows for excellent bond strength and repeatability. It has zoom optics and alignment features with an optional adaptor to feed and guide the wires accurately. This product is also equipped with a total of eight programmable bond channels and multiple options for wiring requirements. It is also designed with a patrick bridge mechanism for stability and is capable of making up to ten thousand bonds per hour. WESTBOND 7400A has an integrated workspace that enables a user to monitor and control the process. Users can view wire parameters, program parameters, machine conditions and process status or reports from the same interface. The device also contains a 3D monitor that provides visual overview of the bonding process. Overall, WESTBOND 7400 A provides the user with a powerful and versatile tool to carry out the wire bonding procedure. It can provide precise wire bonding with its intuitive programming system and reliable features for ensuring superior performance. With these features, 7400A provides the user with a reliable and versatile device for carrying out the wire bonding process.

There are no reviews yet