Used WESTBOND 7476E #9314755 for sale

URL successfully copied!

Tap to zoom

ID: 9314755

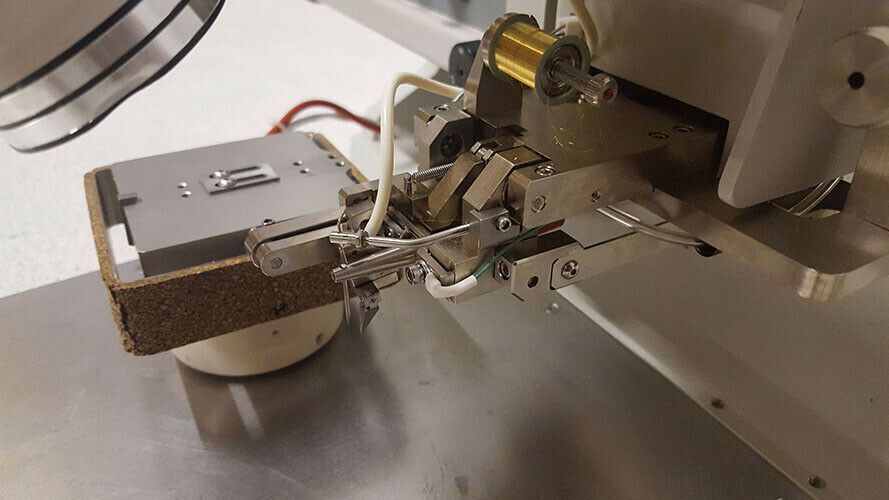

Wire bonder

Bonds aluminum / Gold wire: 0.7 mil to 2 mil (1mil =0.001" ~ 25µm) Diameter

Al wire bonding: Wedge-wedge technique using ultrasonic energy at room temperature / Au wire bonding: Work piece heat

Wire is threaded and clamped diagonally at 45° wire feed assembly

Independent feeding: Front to back bonding direction

Three-axis micromanipulator: Work-plane with range of motion 0.562" Vertical and 0.625" horizontal direction

Forward pivot tool assembly: K-Sine transducer operated at 63 KHz and 8 Vrms

(30) Separate buffers of bond setting

40-Character LCD screen

Power supply: 115/230 V, 50/60 Hz.

WESTBOND 7476E is a high-precision bonder that is designed to work with a variety of materials, ranging from metals, semiconductors, and plastics. This wire bonding machine utilizes a range of thermal and mechanical techniques to create strong and reliable interconnections. It features an upgraded design compared to its predecessors, allowing for more efficient and accurate bonding of different materials. The machine features a fully integrated digital system that ensures precise temperature and pressure readings are maintained. The control console of the machine can be used to set target temperatures, set pressure values, as well as program wire lengths. There is also an adjustable standoff height and a fully programmable wire feeder, providing the user with the capability to adjust the feed speed and type of wire being used. 7476E offers several unique features for improved performance. This includes its PulsED Heat System, which uses pulse-controlled heating to enhance bonding performance by providing uniform heating of the entire work area. This is best suited for delicate bonding operations and ensures consistent results. Additionally, there is vacuum-sealed wire coiling technology that ensures consistent resistances and repeatable results. WESTBOND 7476E also includes sonar height monitoring technology that constantly checks the wire length, allowing for precise and controlled descents of the bond head. This ensures the wire is placed in the exact position that the user desires. The bond pad is heated using graphite hot plates, which provide a controlled heating of the substrate for optimal bond formation. 7476E is an excellent choice for a variety of bonding operations, including fine-pitch thermocompression, wedge, and ball bonds. This product is designed to help organizations improve their production quality, reduce their production costs, and make their bonding operations more efficient.

There are no reviews yet