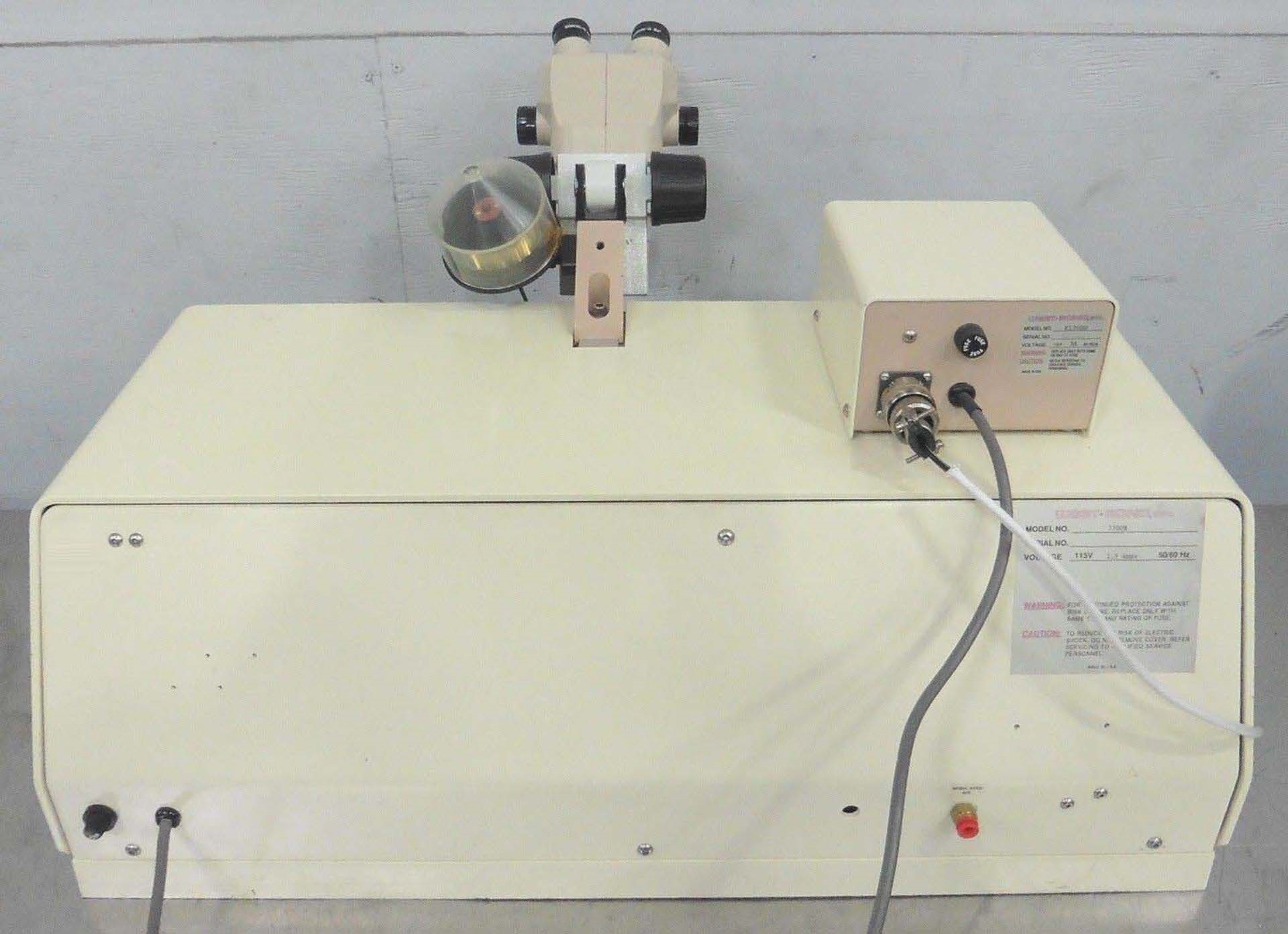

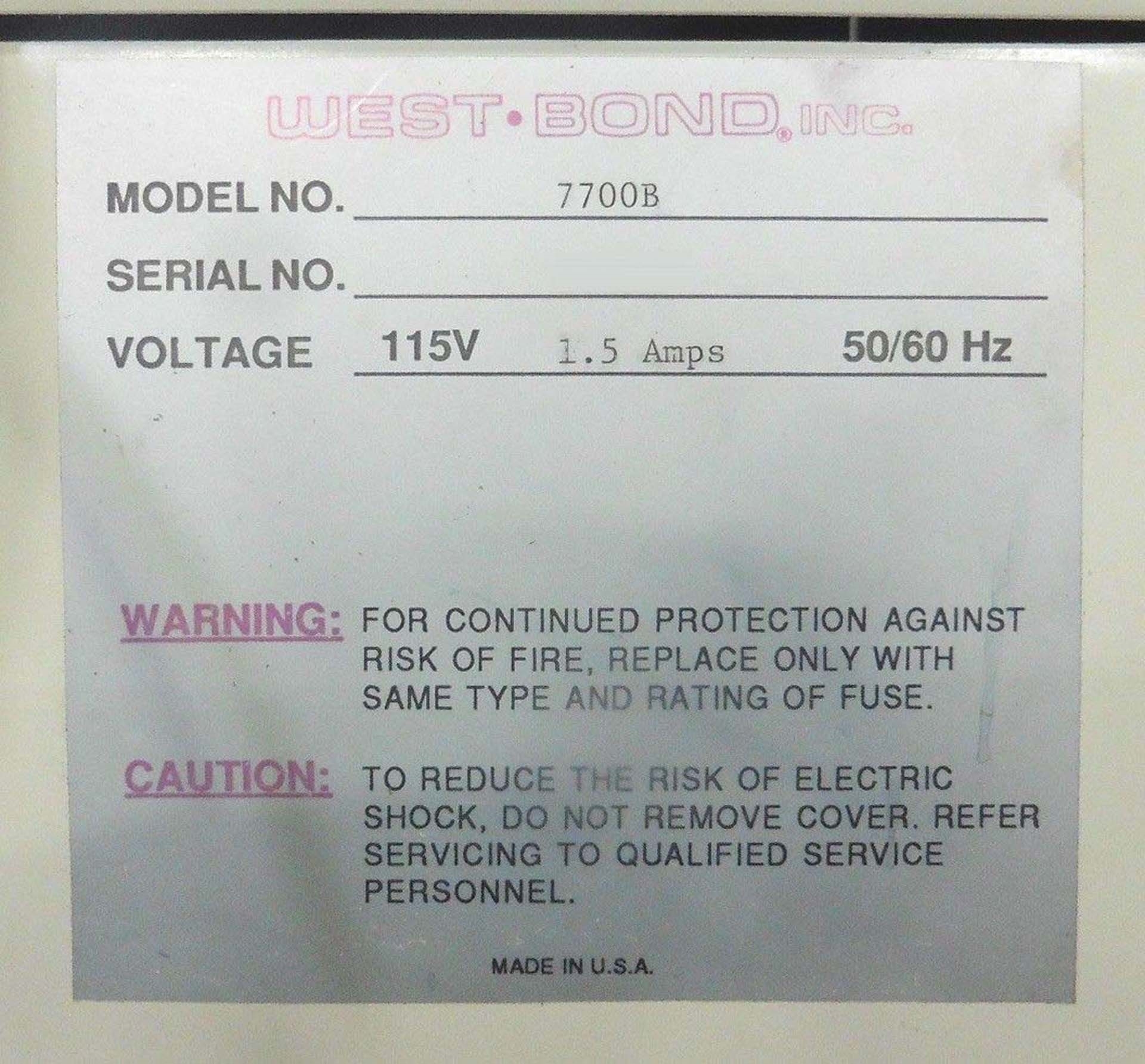

Used WESTBOND 7700B #9238987 for sale

URL successfully copied!

Tap to zoom

ID: 9238987

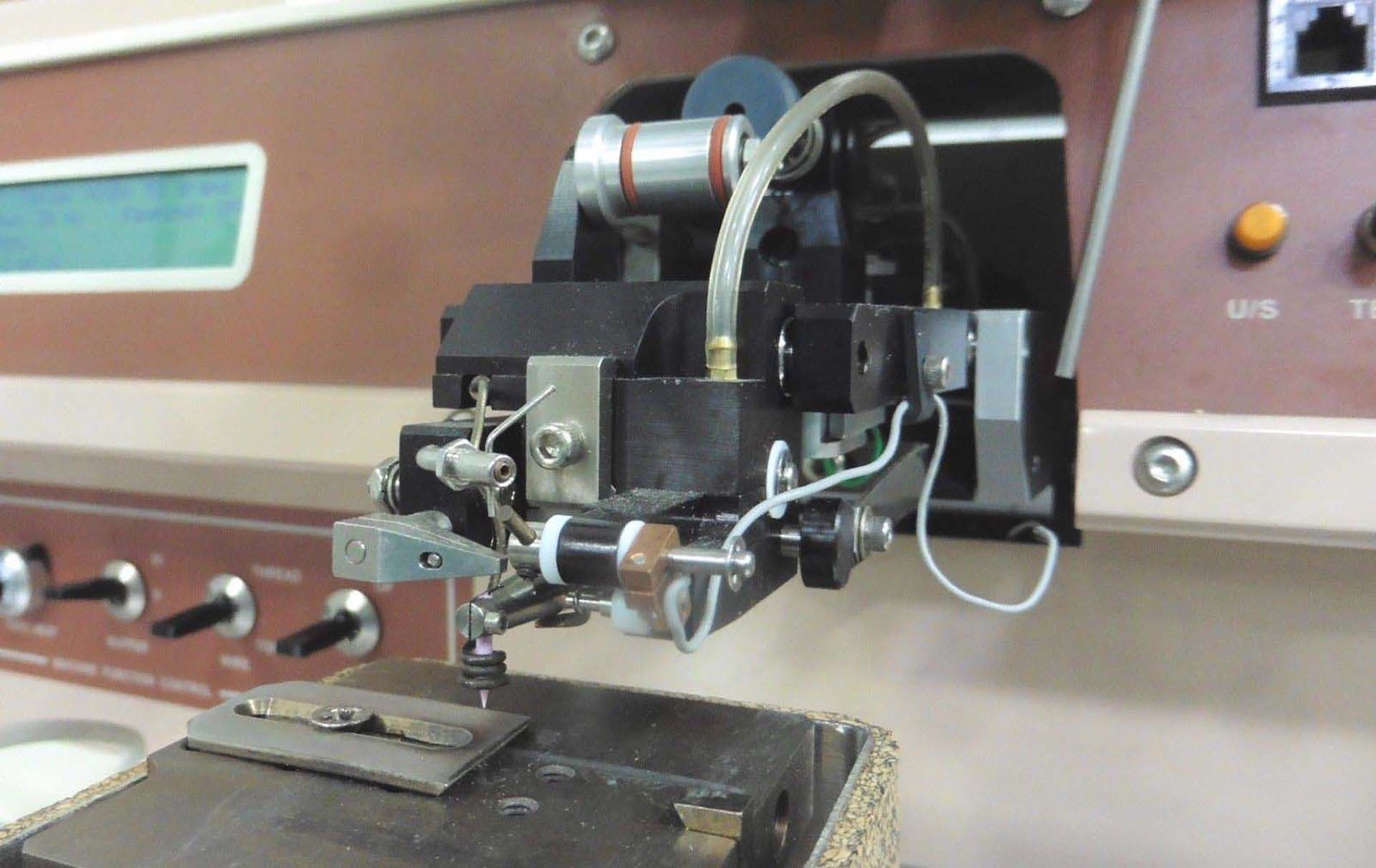

Gold ball wire bonder

BAUSCH & LOMB Stereo Zoom 4 Microscope

Eyepieces: 0.7x to 3.0x

Heated work holder with temperature controller.

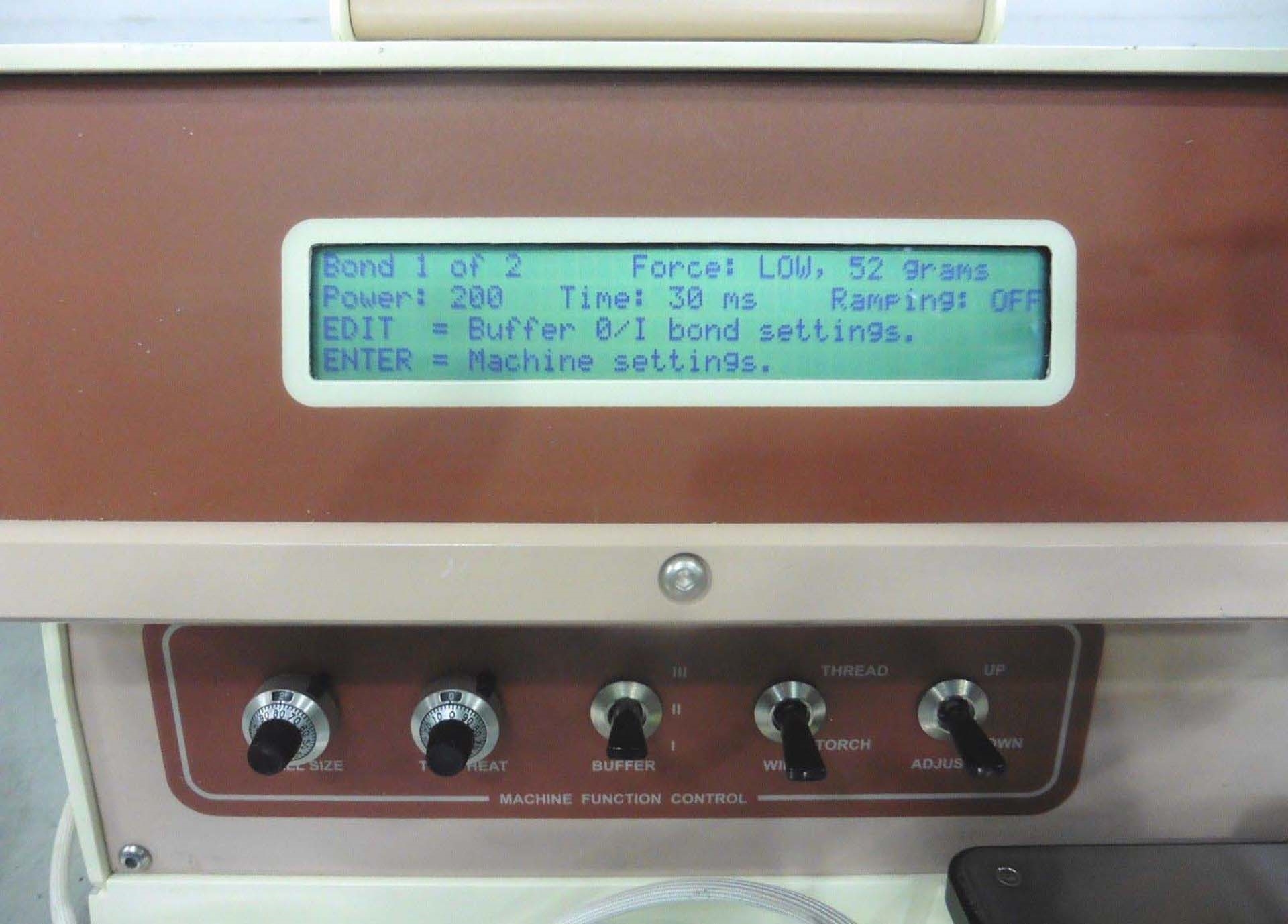

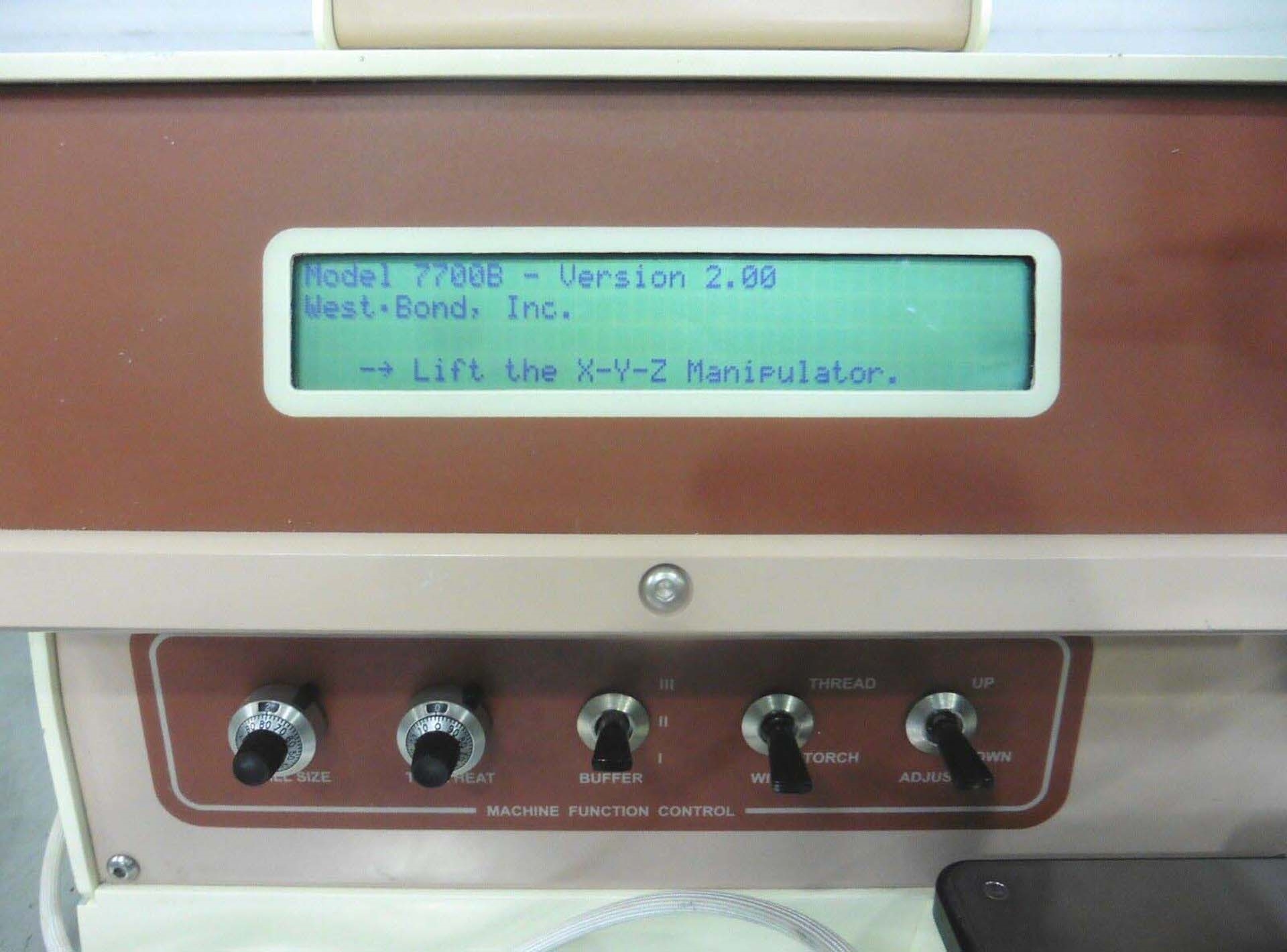

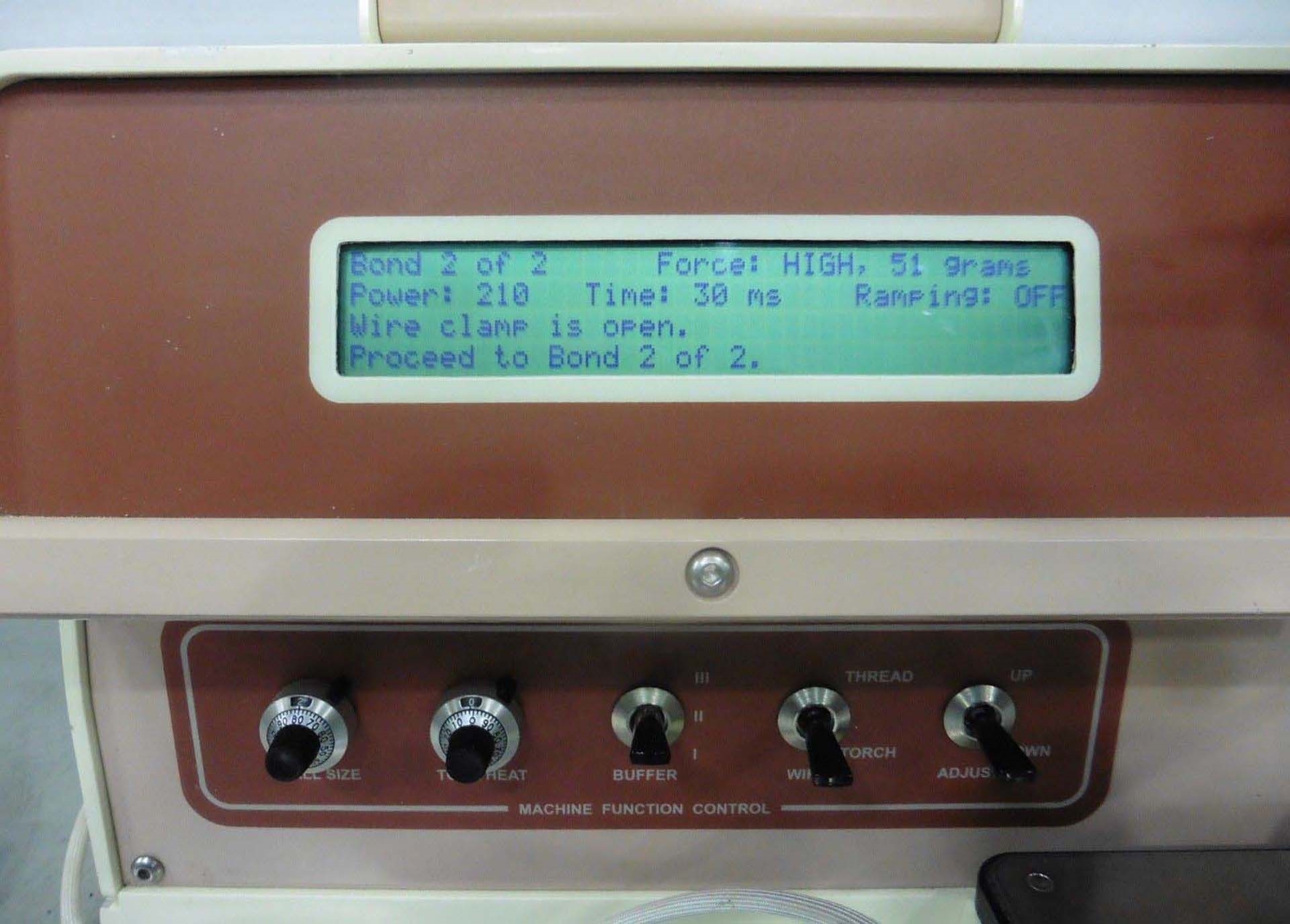

WESTBOND 7700B is a fully automated, operator-friendly bonder that is engineered to streamline production lines. It is a versatile bonder that is suitable for wafer bumping, tape automated bonding (TAB), and flip chip applications. 7700B is suitably equipped with a conveyor, frame, and a sophisticated vision alignment equipment. This allows the machine to accurately align each component which increases its flexibility and reduces its cycle times. The bonder has an intuitive and user-friendly touch screen control panel that provides operators with the capability to quickly and easily access, program, and control the machine. WESTBOND 7700B is built with a robust system of robotic arm, programmable z-axis station, and automated x-y-z positioning stages. The robotic arm is equipped with an advanced servo-motor drive unit and can reach up to a maximum speed of 100 inches per second. This efficient machine makes the machine suitable for bonding and reliable for uni- and multi- die component analysis. Furthermore, the programmable Z-axis station ensures that components are placed precisely in the desired location in one-dimensional vertical directions. The automated X-Y-Z positioning stages allow for x-, y-, and z-axis positioning accuracy up to a resolution of 0.00025". 7700B is equipped with a profile-enabled vision alignment tool, which ensures precise component placement. This asset is also equipped with a shock detector, that ensures that components do not suffer from damage due to bonder vibrations by automatically detecting and shutting down the machine. Furthermore, the bonder includes a thermal control technology to ensure each bond is free from thermal distortions. It is also equipped with a vacuum pick-up model. This makes the machine suitable for attaching multiple components with varying sizes and shapes. The vacuum pick-up equipment is easy to use and is specifically designed to increase component placement accuracy. In conclusion, WESTBOND 7700B is highly precise and efficient bonder that is suitable for production lines. It is equipped with a robust robotic arm, a sophisticated vision alignment system, and an automated X-Y-Z positioning stages. It is also equipped with a thermal control technology, a vacuum pick-up unit, and a shock detector to ensure components face minimal damage. The machine is highly efficient, providing fast cycle times and great accuracy for placement.

There are no reviews yet