Used TRANE CVHF049FA1X0LCN2767W7E7TCC0000000EA1G0000000003B1 #9014869 for sale

URL successfully copied!

Tap to zoom

ID: 9014869

Vintage: 2002

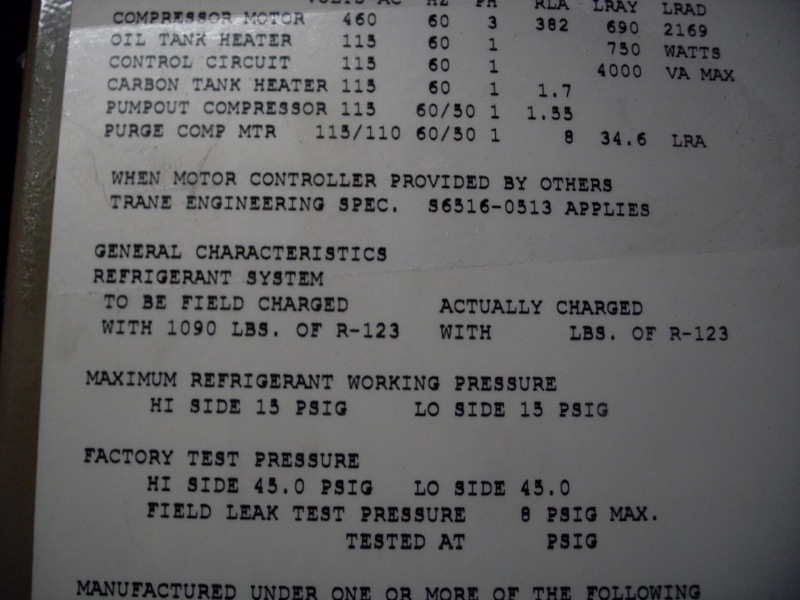

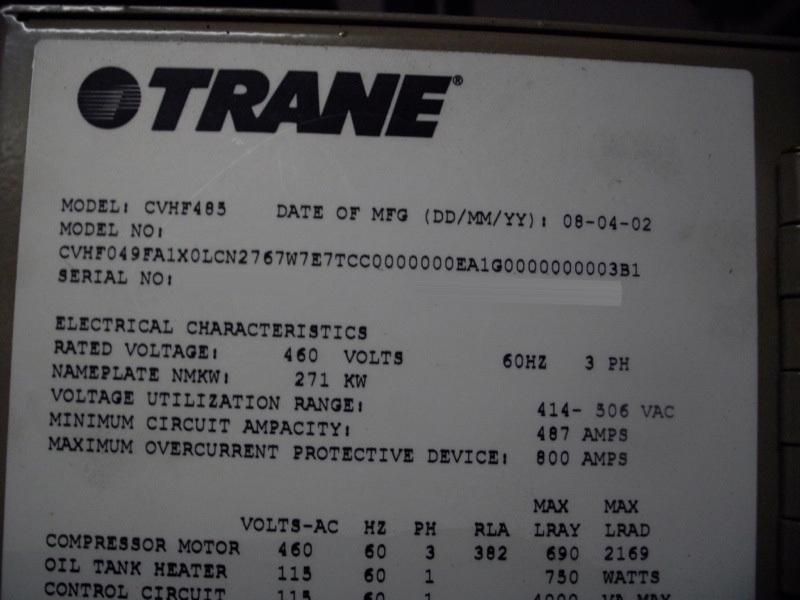

Chiller, 485 ton

42,955 hrs

Chiller:

Chiller heating or cooling mode cooling

Active chilled water setpoint: 42.0°F

Active chilled water setpoint source: front panel

Active current limit setpoint: 100.0% RLA

Active current limit setpoint source: front panel

Evaporator entering water temperature: 47.8°F

Evaporator leaving water temperature: 41.6°F

Evaporator pump control: on

Evaporator water flow switch status (unfiltered): flow

Chiller control signal target: 46.3%

Condenser entering water temperature: 74.2°F

Condenser leaving water temperature: 82.8°F

Condenser pump control: on

Condenser water flow switch status: flow

Chilled water softload target: 42.0°F

Current limit softload target: 100.0%

Event max: 125

Timer max: 60

Circuit:

Evaporator saturated refrigerant temperature: 40.9°F

Evaporator refrigerant pressure: -8.8 psi gauge

Evaporator approach temperature: 0.7°F

Condenser saturated refrigerant temperature: 83.0°F

Condenser refrigerant pressure: 0.0 psi gauge

Condenser approach temperature: 0.3°F

High pressure cutout circuit on

Head relief request relay: off

Maximum capacity relay: off

Compressor:

Compressor refrigerant discharge temperature: 83.1°F

Oil tank pressure: -9.1 psi gauge

Oil pump discharge pressure: 11.4 psi gauge

Oil differential pressure: 20.3 psid

Oil tank temperature: 110.3°F

Oil pump command: on

Oil heater command: on

Inboard bearing temperature: 108.4°F

Outboard bearing temperature: 95.6°F

Inlet guide vane position first stage: 26.9%

Inlet guide vane position first stage: 13,685 steps

Motor:

Restart Inhibit Time (MP): 0:00 mins:secs

Starter Current L1 %RLA: 56.5 % RLA

Starter Current L2 %RLA: 57.5 % RLA

Starter Current L3 %RLA: 57.3 % RLA

Starter Current L1 Amps: 215.0 amps

Starter Current L2 Amps: 220.0 amps

Starter Current L3 Amps: 219.0 amps

Starter Voltage Phase AB: 480 volts

Starter Voltage Phase BC: 481 volts

Starter Voltage Phase CA: 479 volts

Average Line Current: 57.1 % RLA

Average Line Current: 218.0 amps

Starter Max Current: 55.9 % RLA

Starter Average Phase Voltage: 480 volts

Starter Load Power Factor: 0.81

Starter Power Consumption: 135 kW

Starter Power Demand: 62 kW

Starter Energy Consumption - Resettable: 3,673,414 kWh

Starter Energy Consumption Last Reset December 31, 1979 12:00:00 AM

Starter Energy Consumption - Non Resettable: 3,673,414 kWh

AFD Output Power: 125 kW

AFD DC Bus Voltage: 646 volts

Motor Winding Temperature #1: 92.9 °F

Motor Winding Temperature #2: 92.9 °F

Motor Winding Temperature #3: 92.4 °F

AFD Transistor Temperature: 112.3 °F

Speed: 3,399 rpm

Frequency: 57.0 Hz

Frequency Command: 57.0 Hz

Boundary Pressure Coefficient: 0.57

Pressure Coefficient: 0.58

Re-optimization Time Remaining: 00:00 hrs:mins

AFD Last Diagnostic Code (decimal): 0

Purge:

Time Until Next Purge Run: 0:00 mins:secs

Daily Pumpout-24 Hours: 1:16 mins:secs

Average Daily Pumpout-7 Days: 1:03 mins:secs

Chiller On-7 Days: 6.3 %

Pumpout Chiller On-7 Days: 6.7 %

Pumpout Chiller Off-7 Days: 93.3 %

Refrigeration-Life: 41630:56 hrs:mins

Pumpout-Life: 16788:30 mins:secs

Purge Refrigerant Compressor Suction Temp: 80.6 °F

Purge Carbon Tank Temp: 74.3 °F

Purge Liquid Temperature: 83.0 °F

Pumpout Time Since Last Regeneration: 78:50 mins:secs

Time at Last Regeneration: March 14, 2011 1:52:00 PM

Pumpout Total at Last Regeneration: 16709:40 mins:secs

Absorptive Capacity: 84.2 %

Carbon Regen Cycles: 67

2002 vintage.

TRANE CVHF049FA1X0LCN2767W7E7TCC0000000EA1G0000000003B1 chiller is an industrial grade air conditioning equipment designed for commercial grade applications. It is a high-efficiency Variable Air Volume (VAV) system tailored for any type of commercial setup, including offices, retail stores, restaurants, schools, warehouses, and many other industrial settings. It is an energy-efficient air conditioning solution taking advantage of the latest technology to maximize energy savings and reduce emissions. The major components of this chiller unit are the compressor, condenser, evaporator, expansion valve, and fan motor. The compressor is a single screwdesign, allowing for a consistent and reliable outputof refrigerant gas to the evaporator. The condenser is designed to extract the heat from the returning refrigerant allowing it to be cooled back down to provide the necessary cooling to the conditioned space. The evaporator coils are a multiple-row coil design, allowing for a more efficient transfer of heat into the circulating air and allowing the air to be cooled down to the desired temperatures. The expansion valve helps with the delivery of the refrigerant gas and the maintenance of a constant pressure on the machine. Finally the fan motor further helps to circulate the cooled air on the entire space. This TRANE chiller can also be set up with a variety of controllers and accessories to enable maximum efficiency and user comfort. The SSCP controllers are available to allow for efficient operation with intelligent monitoring of the tool, providing diagnostic information and data logging. Many accessories such as variable frequency drives, economizers, and other devices can also be connected to the asset to ensure optimum performance. All of these components are designed and programmed to work in perfect harmony, providing enhanced comfort and reduced energy costs. CVHF049FA1X0LCN2767W7E7TCC0000000EA1G0000000003B1 chillers have a wide range of benefits in a commercial HVAC setting. Not only are they extremely reliable and efficient, they will also reduce energy costs, reduce emissions and provide safer working environment due to the accurate temperature control. The VAV model also allows for independent temperature control in each zone, allowing every user to enjoy the perfect temperature in their space. Easy installation and maintenance make this an ideal air conditioning solution for any commercial venue.

There are no reviews yet