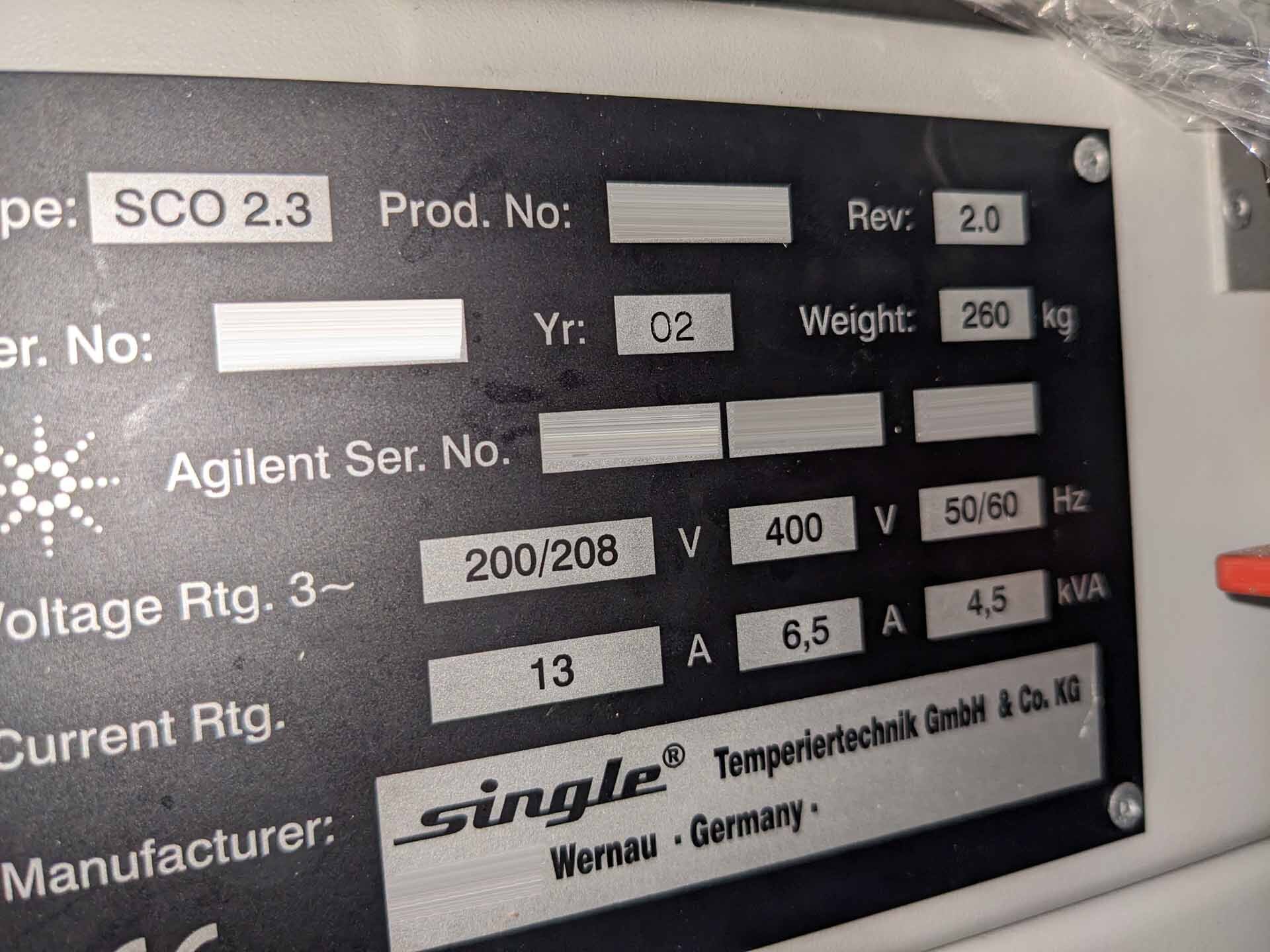

Used SINGLE TEMPERIERTECHNIK SCO 2.3 #293645492 for sale

URL successfully copied!

Tap to zoom

SINGLE TEMPERIERTECHNIK SCO2.3 is a chiller equipment designed for cooling and heating applications in commercial, industrial and automotive applications. It is a recirculating, heat exchanger system that operates based on the principle of air-flow transfer. The chiller unit consists of a fan, compressor, condenser and evaporator. The fan creates an airflow to transport the heated air away from the evaporator and toward the condenser. The compressor compresses the cooled refrigerant gas which is then blown through the condenser as a gas. The condenser cools the gas and it then condenses back into a liquid. The liquid enters the evaporator, which is powered by an electric motor and a fan. The evaporator absorbs the heat from the air and the liquid is subjected to a low pressure so that it boils and evaporates. The circulation process continues as the evaporated refrigerant is compressed again and recirculated. SINGLE TEMPERIERTECHNIK SCO 2.3 chiller machine has several advantages over traditional cooling systems. First, it is more efficient as it does not require the use of hot coils for cooling. Additionally, there is no need to use a closed cooling tool as the recirculating design prevents the refrigerant from becoming too hot or being continuously exposed to air. Finally, its simplified design requires fewer components and requires less maintenance. The main drawback of SINGLE TEMPERIERTECHNIK SCO 2.3 asset is that it is not as powerful as other systems. Additionally, the recirculating design increases the risk of contamination, as any particles that enter the model can be exposed to the compressor and condenser and could result in damage. Overall, SINGLE TEMPERIERTECHNIK SCO 2.3 chiller equipment is an efficient and reliable solution for cooling and heating applications. Its efficient design is easy to maintain and requires fewer components than other systems. The main drawback is the lack of power compared to other cooling systems, as well as the risk of contamination by particles.

There are no reviews yet