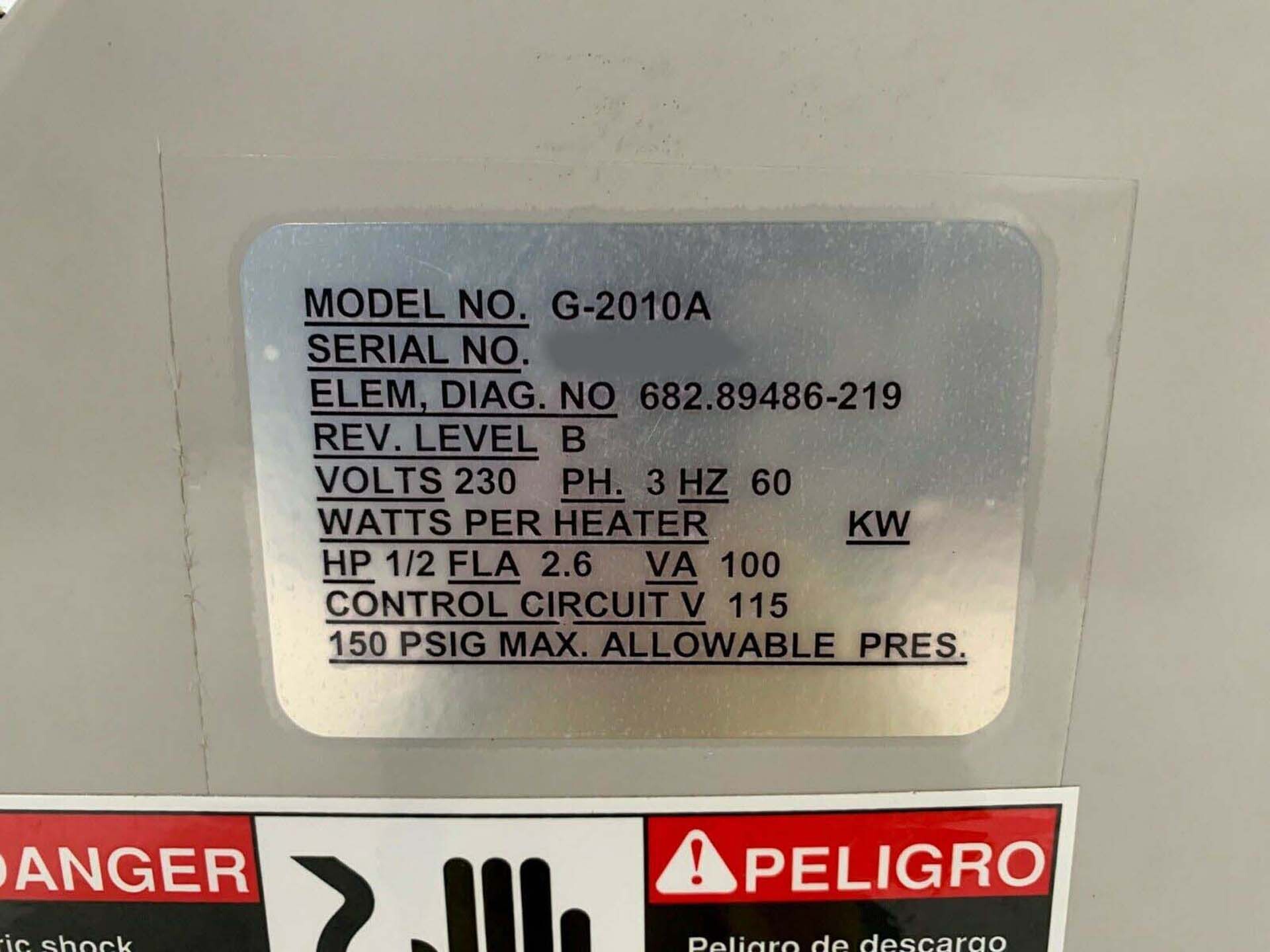

Used STERLING G-2010A #9408021 for sale

URL successfully copied!

Tap to zoom

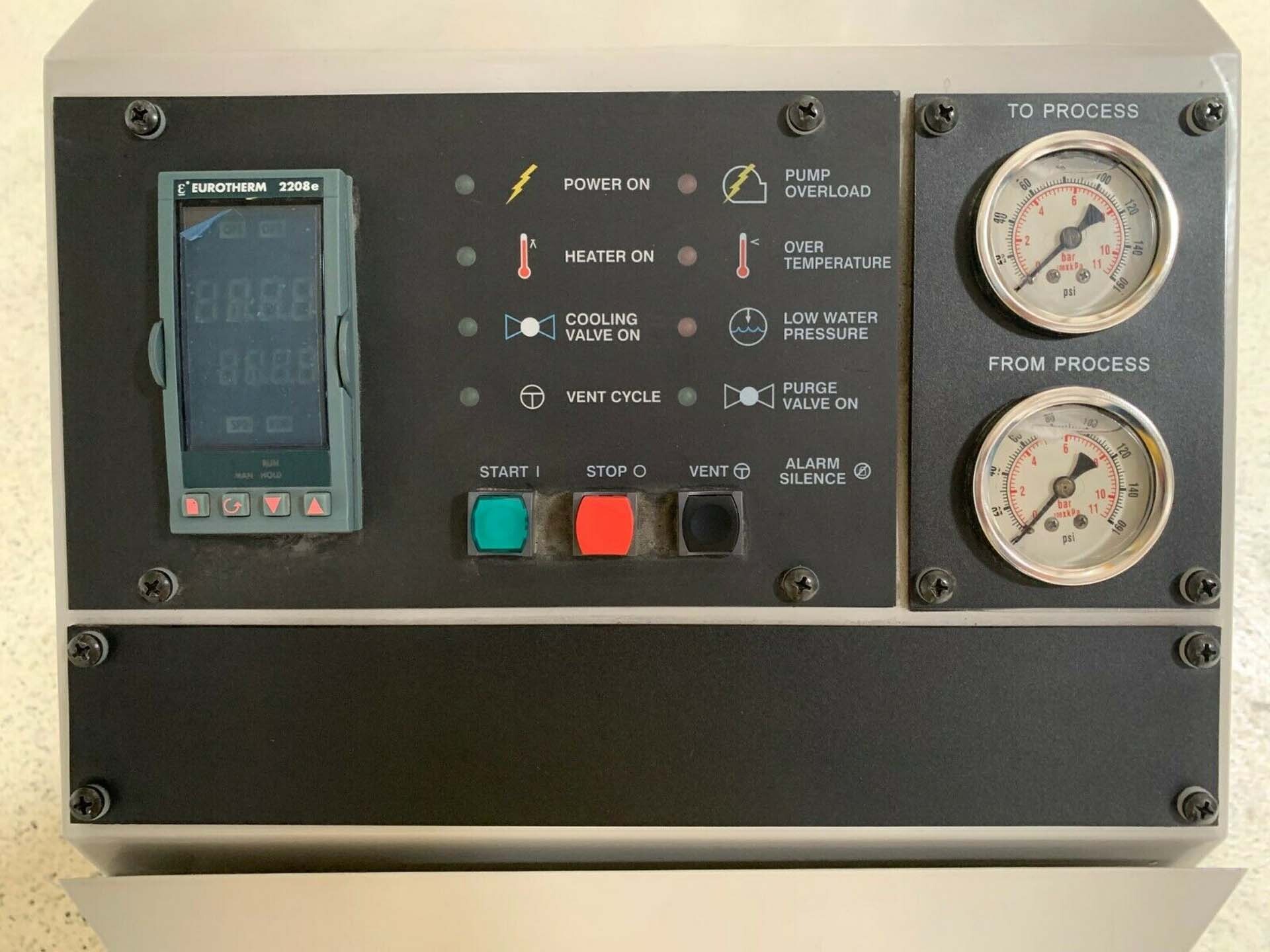

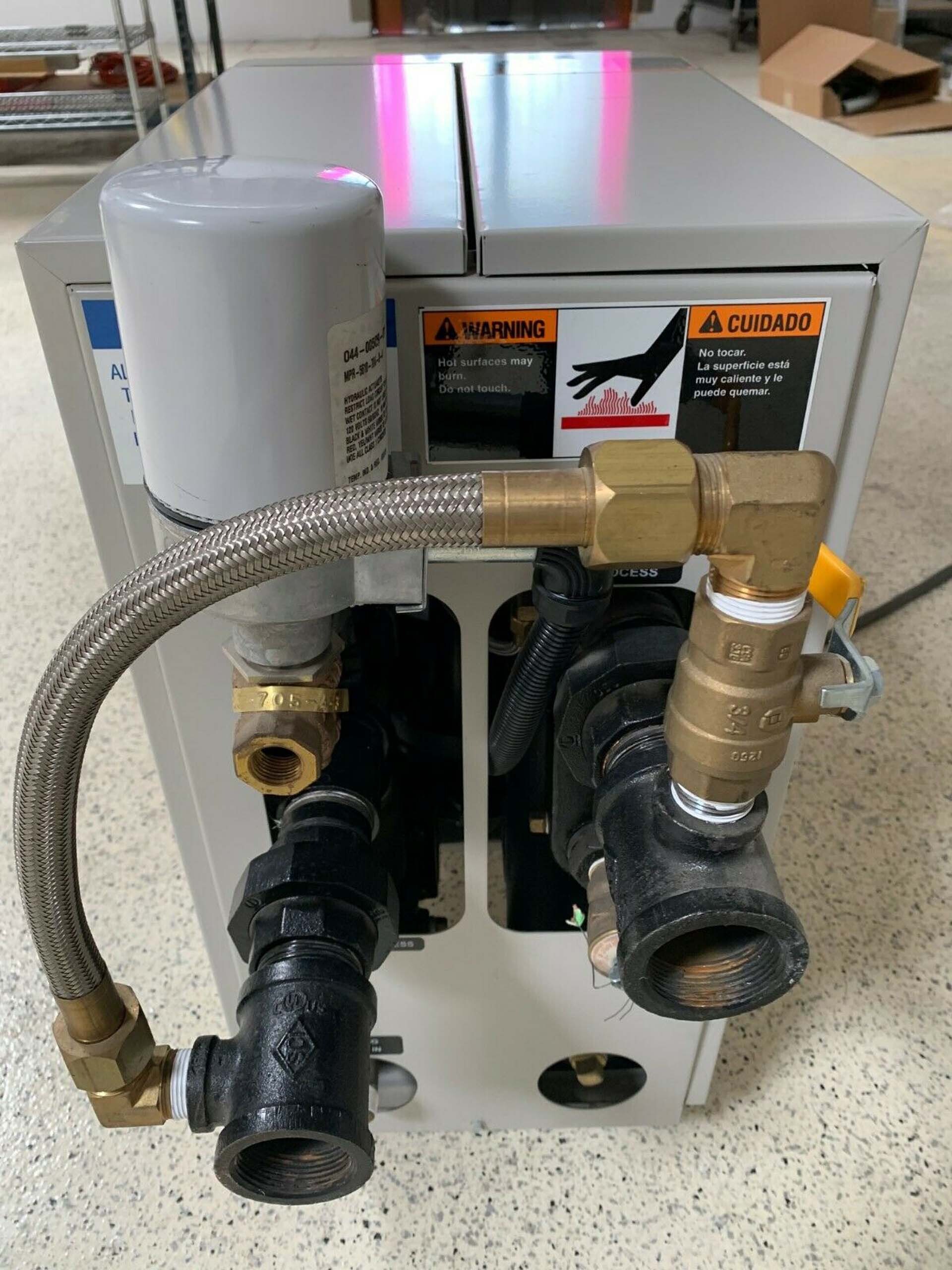

STERLING G-2010A is a recirculating heat exchanger designed to provide reliable cooling power to any laboratory or industrial process. This equipment uses an industrial-strength fan to circulate a coolant through a closed loop system. The coolant is kept at a specific temperature, which is monitored by a digital temperature controller. G-2010A is particularly well suited for applications involving permanent or temporary cooling of medium- to large-scale cooling requirements that wouldn't be able to be satisfied using water-cooled chillers. The heat exchanger portion of STERLING G-2010A is composed of two key components—a heat sink and a thermal conducting coil. The heat sink is engineered to rapidly dissipate heat energy from the process fluids, while the thermal conducting coil is designed to transfer the energy from the heat sink to the cooling coils. This efficient transfer of energy helps to maintain temperature stability within the process fluids even under high loads. Additionally, the heat exchanger's sealed design helps to avoid any potential contamination of the unit by external materials. The primary cold-producing component of G-2010A is a reciprocating compressor. The compressor is designed to ensure a consistent supply of cold air to the process fluids. The compressor circuit contains a number of components, including an air inlet/outlet, suction filters, suction line, suction shutoff, discharge shutoff, refrigerant line, automatic expansion valve, oil separator, motor control, and a discharge bypass valve. The motor control helps the unit maintain optimal cooling temperatures, while the bypass valve is used to reduce unit load when the machine is not under demand. STERLING G-2010A also features several safety features to protect against unsafe operating conditions. Features include: a fan shutoff safety switch, temperature and pressure shutdown/monitor, compressor overload protection, and a low-oil level cutoff. The fan shuts off automatically when the unit is not in use, while the temperature and pressure shutoff/monitor helps the unit to remain safe during operation by monitoring pressure, temperature, and current. The compressor overload protection prevents the unit from being overworked, and the low-oil level cutoff ensures that the unit is lubricated at all times. G-2010A is an efficient and reliable chiller that provides temperature stability and power even under high loads. The tool's sealed design and several safety features provide users with peace of mind, while the high performance operation of the reciprocating compressor and heat exchanger ensure dependable operation. All components in STERLING G-2010A are designed for optimal long-term operation, and comprehensive instructions are provided for easy installation and maintenance.

There are no reviews yet