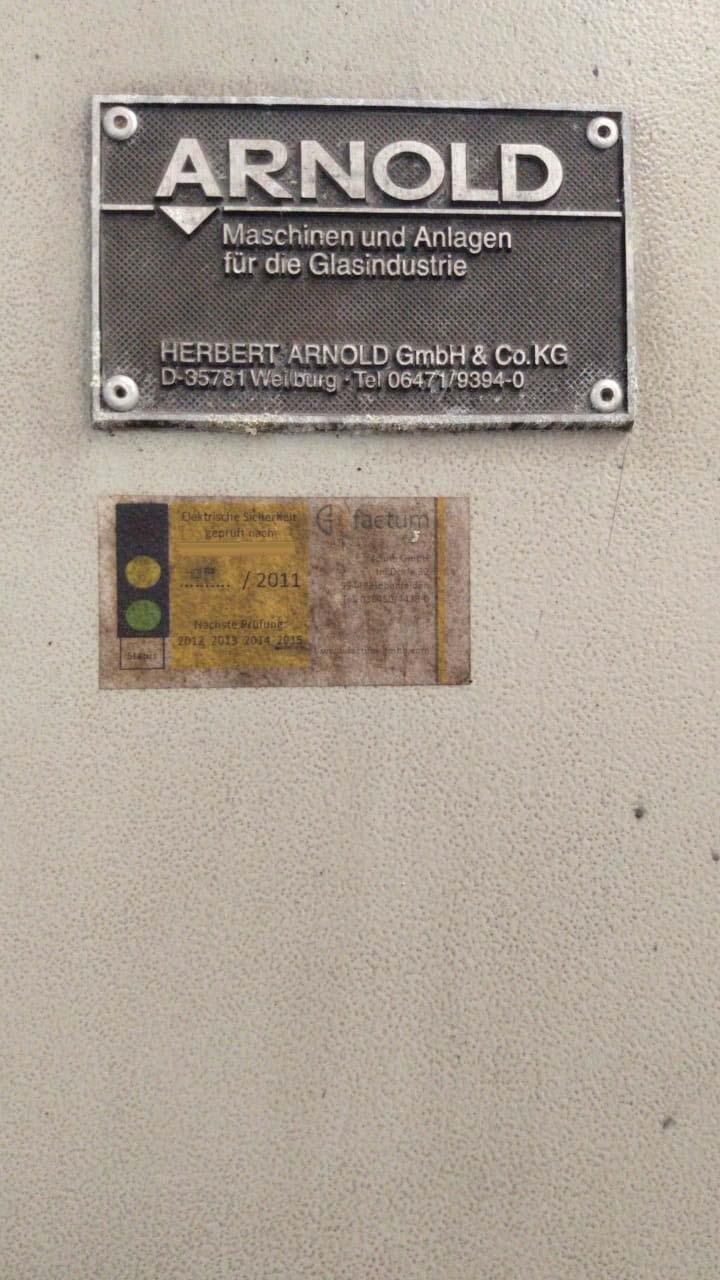

Used HERBERT ARNOLD 72/475 #9281103 for sale

URL successfully copied!

Tap to zoom

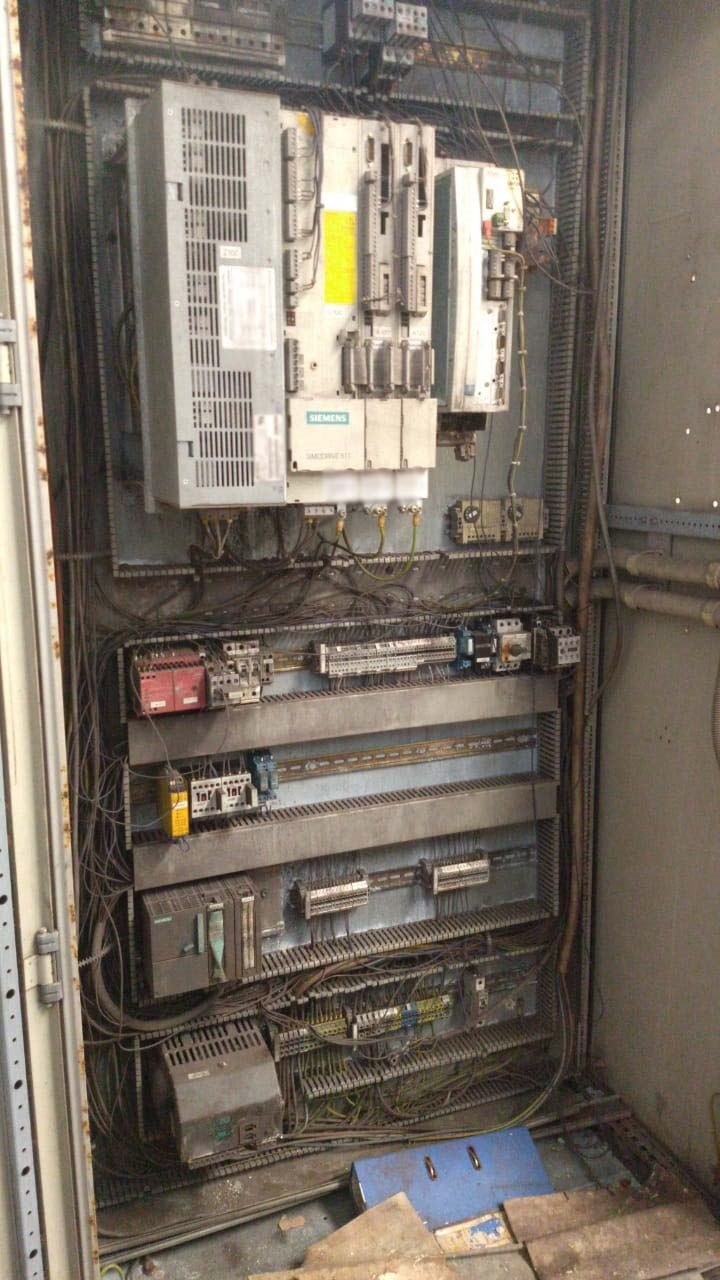

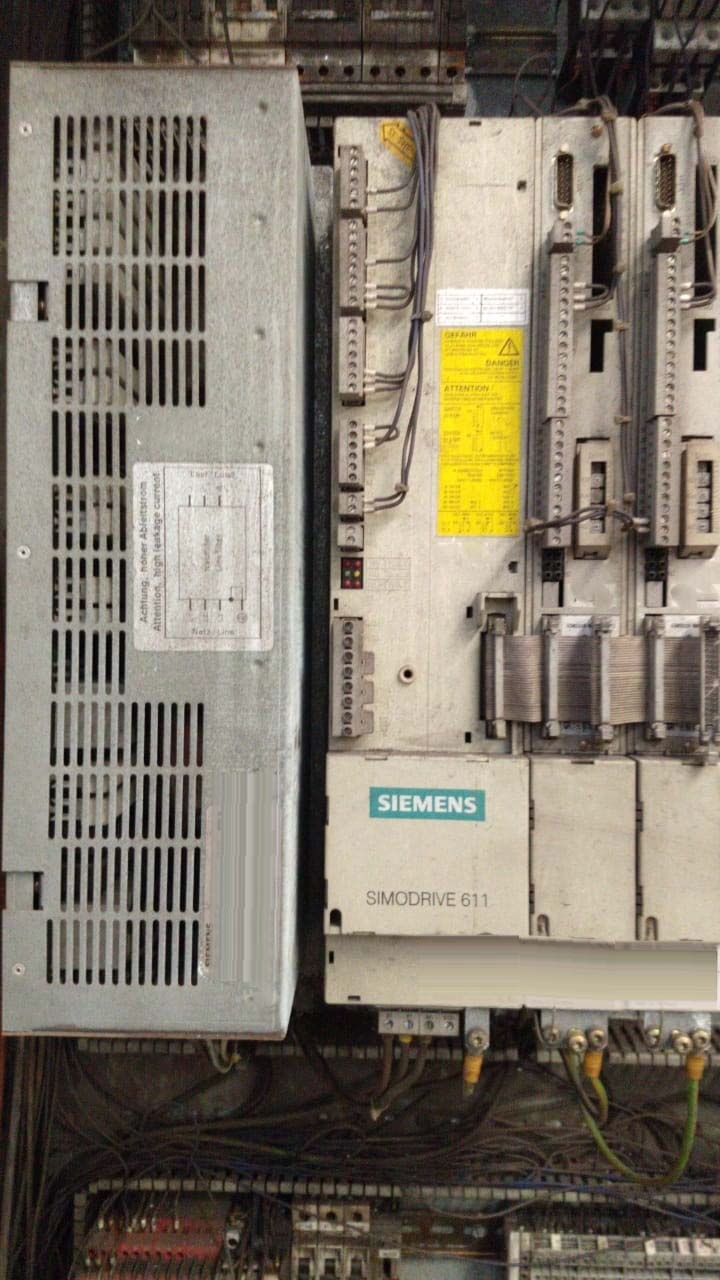

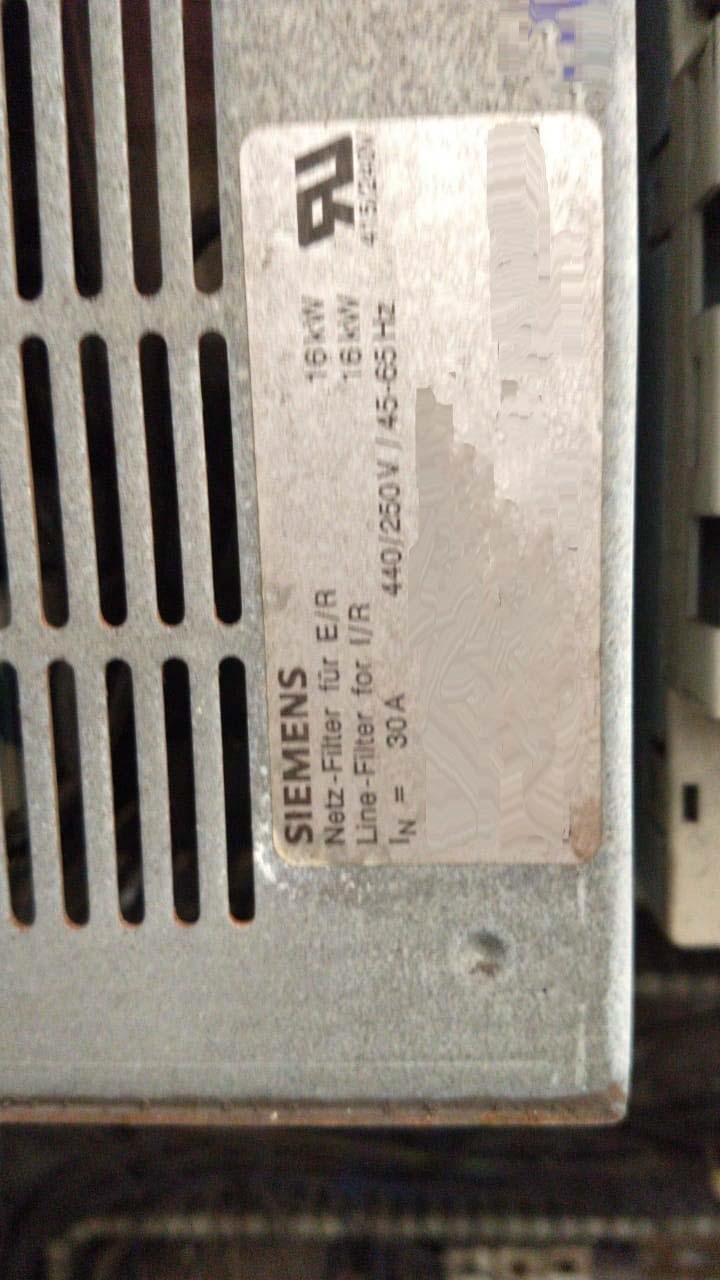

HERBERT ARNOLD 72/475 Crystal Growing, Sawing & Slicing Equipment is a powerful precision instrument for growing, sawing and slicing crystals for research and production. The system is built to the highest standards of accuracy and rigidity and uses a CNC controller for high precision operation. It consists of a number of custom built components and accessories specifically designed to grow, saw and slice crystals in an optimal manner. At its core, the unit features a custom built hard tracked gantry robot with a series of precision saw blades and slicing blades mounted onto it. The machine also includes a variety of other components such as a furnace chamber for crystal growth, an ultrasonic bath for cleaning and preparation of crystals, and a cooling stage for efficient sawing and slicing operations. The tool is capable of preparing crystals in various shapes and sizes and it can also grow large crystals with a controllable size range. Additionally, it can easily be used for precision sawing and slicing of single or multiple crystals as it can be programmed with a number of custom cutting parameters. In terms of accuracy, HERBERT ARNOLD 72/475 Crystal Growing, Sawing & Slicing Asset is able to achieve a cutting precision of <1 µm. The precision saw blade is able to cut slices in a range of 5 - 25 µm with a repeatability accuracy of 0.2 µm. Additionally, it is equipped with a built-in autocontrol for monitoring the temperature of the crystal saw and slice. An integrated PC workstation and a touch screen display makes it easy for users to control and adjust every parameter of the model in real-time, as well as store and print results. HERBERT ARNOLD 72/475 equipment can also be connected to a vacuum system for additional safety when dealing with hazardous materials yet maintaining reliability. To summarize, HERBERT ARNOLD 72/475 Crystal Growing, Sawing & Slicing Unit is a precision instrument for growing, sawing and slicing crystals for research and production. It features a custom built hard tracked gantry robot, a furnace chamber for crystal growth, an ultrasonic bath for cleaning and preparation of crystals, a cooling stage for efficient sawing and slicing operations, as well as a precision saw blade capable of cutting slices in a range of 5 - 25 µm with a repeatability accuracy of 0.2 µm. It's high precision, precise cutting, easy real-time control and integrated PC workstation makes it an ideal choice for crystal cutting in any research or production application.

There are no reviews yet