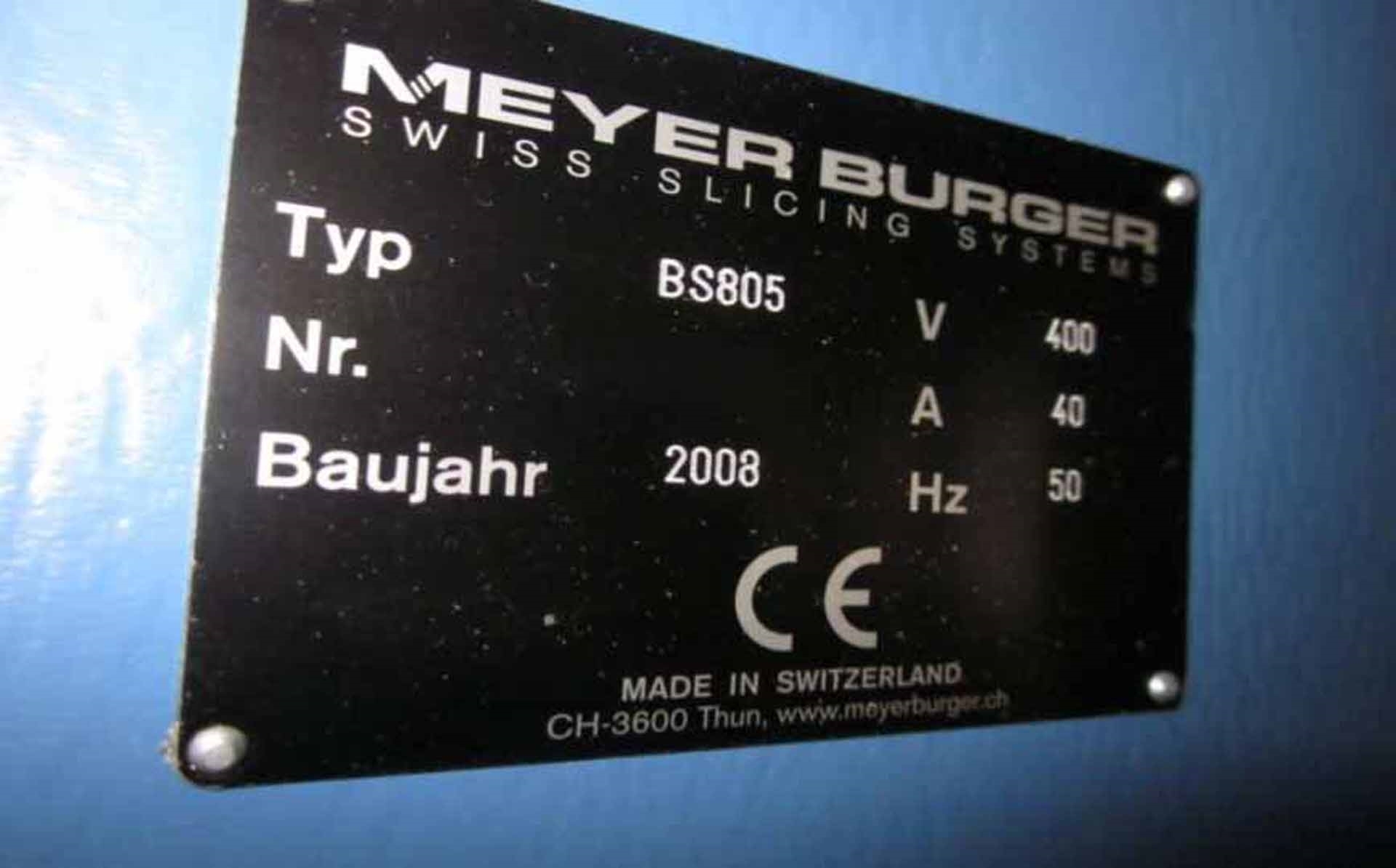

Used MEYER BURGER BS 805 #9225669 for sale

URL successfully copied!

Tap to zoom

ID: 9225669

Vintage: 2008

Band saw

Coolant supply:

Supply tank capacity: 125 Liters

Return tank capacity: 125 Liters

Supply pump: 25 l/min, 6 Bar

Return pump: 100 l/min, 2 Bar

Control system:

Type: SIMATIC

Operating panel: Viscontrol, Touch SCD 1297

Compressed air:

Pressure: 5-8 Bar

Approx 20 m³/h

Connection: Hose fitting for inside hose diameter 13 mm

Coolant supply:

Quantity: Approx 25 l/min

Pressure: 6 Bar

Connection: R 3/4"

Coolant return:

Quantity: Approx 100 l/min

Pressure: 2 Bar

Connection for coolant return exhaust: Ø 25 mm / R 1 1/4"

Exhaust: Ø 70 mm

Air exhaust: Approx 1500 m³/h

Connection: Ø 100 mm / 200 mm

Color coding of pipes:

Black: Oil, grease

Blue: Air

Green: Water

White / Transparent: Emulsions / Slurry

Temperature of machine surroundings:

Room temperature: 15°C - 25°C

Fluctuating during slicing process: ≤ 2°C

Temperature fluctuation: < 0.5°C/h

Humidity of machine surroundings:

Relative humidity: 50% ±10%

2008 vintage.

MEYER BURGER BS 805 is a crystal growing, sawing and slicing equipment designed to produce high-quality silicon carbide and other hard materials for research and commercial applications. This high-performance system utilizes advanced technologies to fabricate wafers from a variety of stable crystalline materials. The unit's automated sawing and slicing process is controlled by a programmable interface and ensures uniform wafer sizes and flatness across the entire batch. The machine also features a highly precise crystal-growing module with an accurate temperature and oxygen regulation to enable the growth of defect-free homogenous crystals. In addition, there is a dedicated sawing chamber featuring diamond-clad blades for cutting wafers quickly and precisely. The intuitive user interface allows for simple setup, while its modular design ensures efficient troubleshooting and maintenance. The tool automatically records all data and stores them locally for later analysis. It also offers a wide variety of safety and in-process monitoring features, as well as software controlled parameters to customize the crystal slicing process according to the user's needs. To ensure maximum asset stability and functionality, MEYER BURGER BS-805 employs advanced thermal-management methods to maintain an optimal operating temperature. The model's efficient air-cooling and air-flow management also prevent overheating and enable a consistent environment to ensure reliable outcomes over extended periods. The equipment's accuracy and fast throughput can be further enhanced with custom-made plates and additional components for custom applications. In addition, it is also designed to integrate easily with existing production processes and other equipment for maximum efficiency. Overall, BS 805 is a reliable and highly flexible system designed for cutting and slicing single-crystal materials. It offers efficient cooling solutions and automated control for optimal product output with minimal waste. The unit ensures uniform results with superior performance and extended operational lifetime.

There are no reviews yet