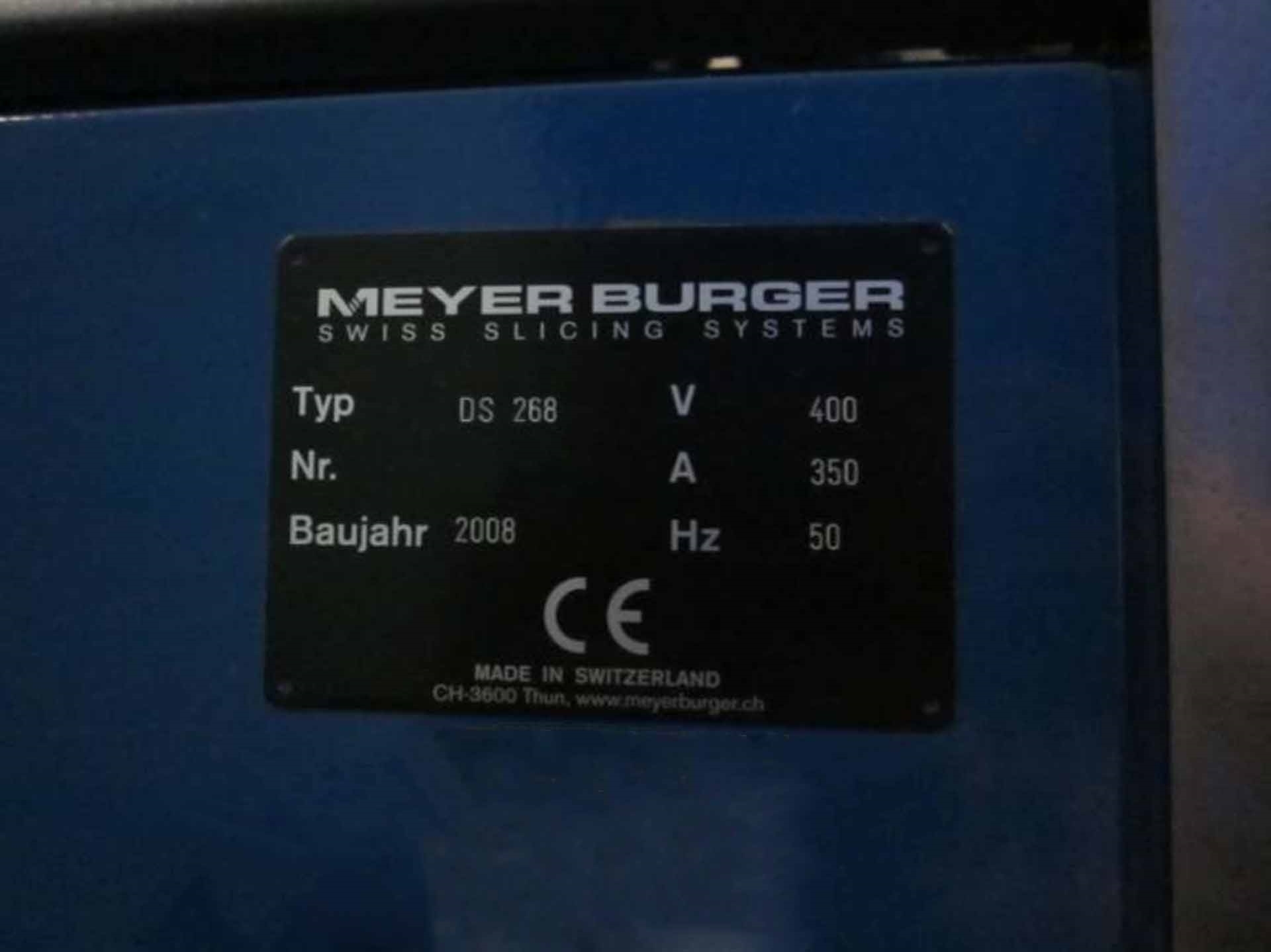

Used MEYER BURGER DS 268 #9225692 for sale

URL successfully copied!

Tap to zoom

ID: 9225692

Vintage: 2008

Slurry wafer saw

Compressed air:

Pressure: 5.5 - 7 Bar

Quantity: Approx 20 m³/h

Connection: Hose fitting for inside hose diameter 13 mm

Water:

Water quality:

Clean water, free of substances produced by rust and algae

pH value: 6.5 - 8.5

Total hardness: 6° - 8°dH

Water requirement: Max 350 l/min

Temperature difference input/output: ~6°C

Min / Max pressure: 2-4 Bar (Differential pressure of installation pipe must be at least 2 bar)

Cooling capacity: 140 kWh

Air exhaust: Approx 500 m³/h (at connection)

Connection: PVC Pipe, internal Ø 200 mm

Color coding of pipes:

Black: Oil, grease

Blue: Air

Green: Water

White / Transparent: Emulsions / Slurry

Temperature of machine surroundings:

Room temperature: 15°C - 25°C

Fluctuating during slicing process: ≤ 2°C

Temperature fluctuation: < 0.5°C/h

Humidity of machine surroundings:

Relative humidity: 50% ±10%

2008 vintage.

MEYER BURGER DS 268 is an advanced crystal growth, sawing and slicing equipment, designed to enable companies to benefit from cost-effective production of high-quality mono and polycrystalline solar cells and sapphire wafers. The system is equipped with a single-station furnace with a full-automatic crucible loader and robotic arm for unidirectional and isotropic cutting, sawing and slicing. It is characterized by an enhanced throughput, precise and cost-efficient material handling and easy operation. The unit offers several advantages regarding cost and throughput, including a high level of automation and efficiency. The advanced roof design of the single-station furnace helps reduce particle generation and improve quality, along with offering precise temperature control through tight temperature regulation and excellent gas and temperature homogeneity. Furthermore, the linear furnace features a substantial increase in capacity and can produce up to 370 mono/poly solar cells simultaneously. DS 268 comes with an improved seal and sawing area, featuring an efficient air extraction machine and easily managed robot arms, as well as the latest in robot control technology. Its integrated thermal imaging camera ensures accurate temperature control, resulting in good geometric accuracy of the sawed or sliced parts. Additionally, the heating furnace is equipped with a high-precision weighing tool, enabling precise measurements. The robotic arm allows for unidirectional cutting, so that parts with identical surface area come out in equal proportions, even when the diamond blade is worn out. The asset's cutting parameters are adjustable for each wafer and the robot precisely controls the movement of the diamond blade. The position of the wafer can also be indicated, so that it is cut exactly as designed. MEYER BURGER DS 268 also offers the ability to slice pieces at angles, enabling the production of different types of products. DS 268 produces semiconductor wafers with an extremely high level of precision, ensuring minimal rework and removal of chip defects, while also reducing cutting costs. Additionally, the model is environmentally friendly - it includes an ozone-free exhaust air purification equipment for the furnace, greatly reducing its potential environmental impact. Overall, MEYER BURGER DS 268 is an ideal system for producing mono and polycrystalline solar cells, sapphire wafers, and other photovoltaic and semiconductor products. Its advanced design and automation capabilities result in higher throughput and greater cost-effectiveness than ever before, making it an ideal option for manufacturing efficient and reliable products.

There are no reviews yet