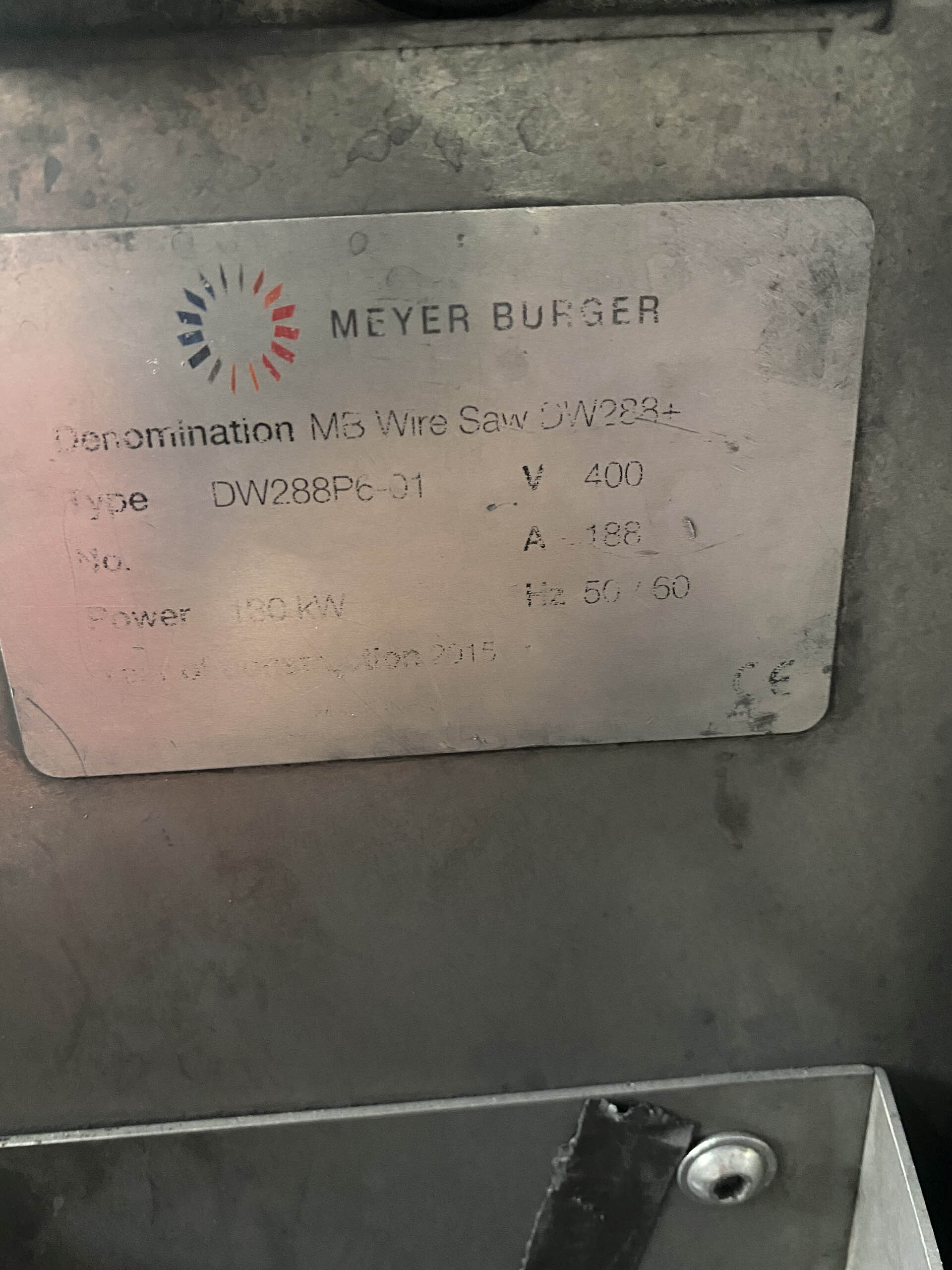

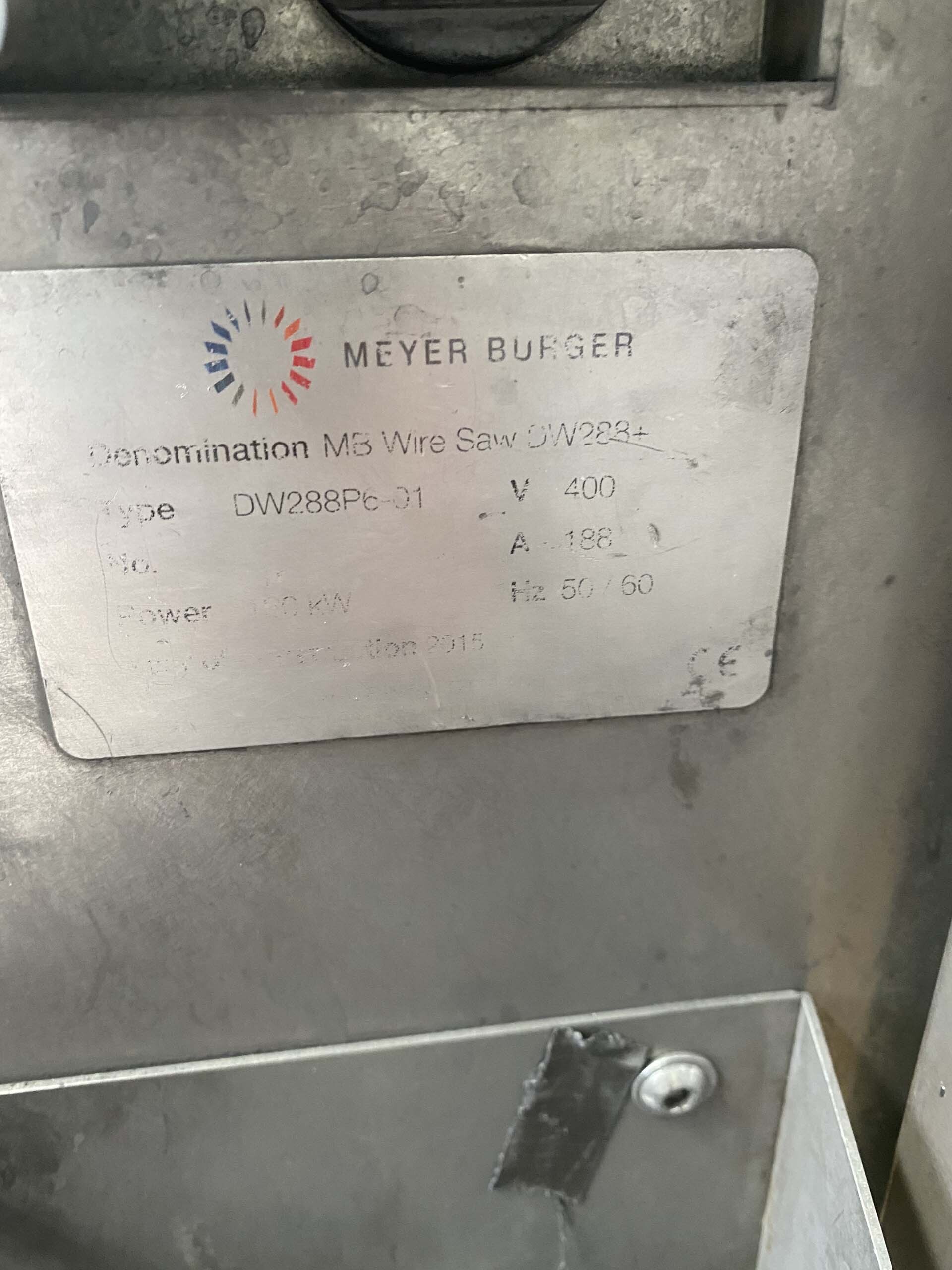

Used MEYER BURGER DW 288 #9384449 for sale

URL successfully copied!

Tap to zoom

ID: 9384449

Vintage: 2015

Diamond wire saw

Work piece dimensions: Automatic clamping system

Cropping inside machine:

Fixed bearing: 30 mm

Movable bearing: 50 mm

Cross section (Max): 156 mm x 156 mm

Cutting direction top down

Feed speed programmable: 0.05-330 mm / min

Wafer thickness (Min) 100μm

Working stroke (Max): 272 mm

Work piece holder:

Length 1: (2) 310 mm

Length 2: 620 mm

Wire management:

Acceleration (Max): 8m/s²

Core diameter (Min): 100μm

(3) Deflection rollers on each side

Deflection rollers / Rollers diameter: 156.6 mm

Direction: Pilgrim / Direction

Split web interface

Wire break detection integrated: < 5

Wire length: 200 mm

Wire length (Total): Depending on wire spool

Wire speed (Max): ±25 m/s

Wire tension :

Max: 30 ±1

Min: 10 ±1

Spool designation:

Wire spool

Working spool

Storage spool

Storage spool (Diamond wire management system):

Diameter: 366 mm

Length: 374 mm

Usable length: 359 mm

(2) Wire guide rollers

Ambient air temperature transport and storage:

Max: + 40°C

Min: + 10°C

Bearing cooling: Water

Roller bearing

Fixed bearing cooling deviation of temperature: ±0.5°C

Horizontal distance between axis: 470 mm

Relative humidity transport and storage: 75%rH

WGR Coating material: PUR

WGR Coating thickness: 6 mm

WGR Diameter (Max): 270 mm

WGR Diameter (Min recommended): 265 mm

WGR Diameter (Min permissible): 262 mm

Wire web: 620 mm

Cutting fluid management:

Cutting fluid (CF) cooling (With heat exchanger, max capacity): 35 Kw

CF Filter, splitter filter: 100 µm

CF Flow (Max): 200 I/min

CF Temperature at nozzle: ± 1°C

Cutting fluid type: Water / Glycol

Interface to the tank hose nipple diameter: 48.3 mm

Tank capacity: 240 L

Tank emptying remaining quantity: 2-5 L

Cooling water (Internal loop):

Antifreeze additive maximum (CS-Pro Plus): 10%

CF Heat exchanger (Max capacity): 35 kW

Temperature range: 22 ±1°C

Water filter strainer size: 0.25 mm

User interface / Control panel:

Operation interface: Process-oriented operation

Screen size, 15"

Type: 1024 x 768

Touchscreen / Joystick

Control system:

Alarm and cut protocol logging

Remote access

Type: SIEMENS Step 7

UPS System integrated

Coloring:

Covers / Doors: Stainless

Electrical cabinet: 7037 RAL

Machine frame: 7037 RAL

Noise level (Max, free field): 71 dB (A)

Compressed air:

Connection (Interface) hose nipple diameter: 12 mm

Consumption: 15Nm³/h

Input pressure (Min): 5.5bar

Particle:

Density (Class 4), max: 8 mg/m³

Diameter (Class 4), max: 0.015 mm

Pressure dew point: +3°C

Residual:

Oil content (Class 4), max: 5mg/m³

Water content (Class 4), max: 6mg/m³

Air exhaust:

Connection PVC pipe depth: 30mm

Inside diameter: 105mm

Quantity: 150 – 250m³/h

Electric system:

Connection power: 130 kW

Electrical standards: EN60204 / EN60439 / EN61439 / EN13849

Clamp cross section:

Maximum: 90 mm

Minimum: 70 mm

Frequency:

Maximum: 60 Hz

Minimum: 50 Hz

Integrated smooth stop: Standard

IP Protection class (Electrical cabinet, touchscreen): IP54

Line voltage: (3) 400 VAC, ±10 %

Line voltage options: (3) 440 / 460 / 480 VAC, ±10 %

Network (Ethernet) connection: RJ 45

Operating power maximum: 130 kW

Operating power typical: 30 kW

Power fuse: 200 A

Prevention against power grid: 24 DC

Shut down time when emergency stop (Time to stop): 3 S

Tolerated mains failure: 10 ms

WGR Motor overload protection: 50 kW

WGR Motor power:

Left: 35 kW

Right: 35 kW

Sun power

PANASONIC

LGE

2015 vintage.

MEYER BURGER DW 288 is an advanced crystal growing, sawing, and slicing equipment specifically designed to process high quality crystalline-ceramics for the electronics and telecommunication industry. It provides maximum precision in all operations for complicated products or sensitive materials. DW 288 system enables the efficient and consistent production of crystalline-ceramics of various sizes and shapes in any quantity. Its advanced crystal growth unit consists of a hybrid susceptor tube, pressure-controlled graphite heat generator, temperature sensor modules, and automatic tuning and B-field alignment systems. These components, together with MEYER BURGER DW 288's advanced temperature management and data logging capabilities, allow for a stable and reliable environment for crystal growth. DW 288 machine's patented sawing and slicing tool is centered around a laser diode and an ultra-low vibration, ultra-precision linear motor. This allows the asset to perform accurate and reliable sawing and slicing operations with high throughput speeds. The sawing and slicing model is also capable of sub-micron accuracy and can support a variety of cutting and trimming operations that are required for the production of fine electronic components and devices. MEYER BURGER DW 288 equipment comes with a user-friendly, intuitive graphical interface. This allows users to program and control the system with ease. The unit also has a fully automated testing and reporting machine for end product quality assurance. This ensures that every product produced with DW 288 tool meets the customers' expectations. MEYER BURGER DW 288 asset is an ideal choice for crystals, ceramic substrates, or other products requiring precision cutting. It provides consistent and accurate cutting results with a high yield, while maintaining a low cost per unit. It is a cost effective and reliable solution for ceramic and crystalline products manufacturing requirements.

There are no reviews yet