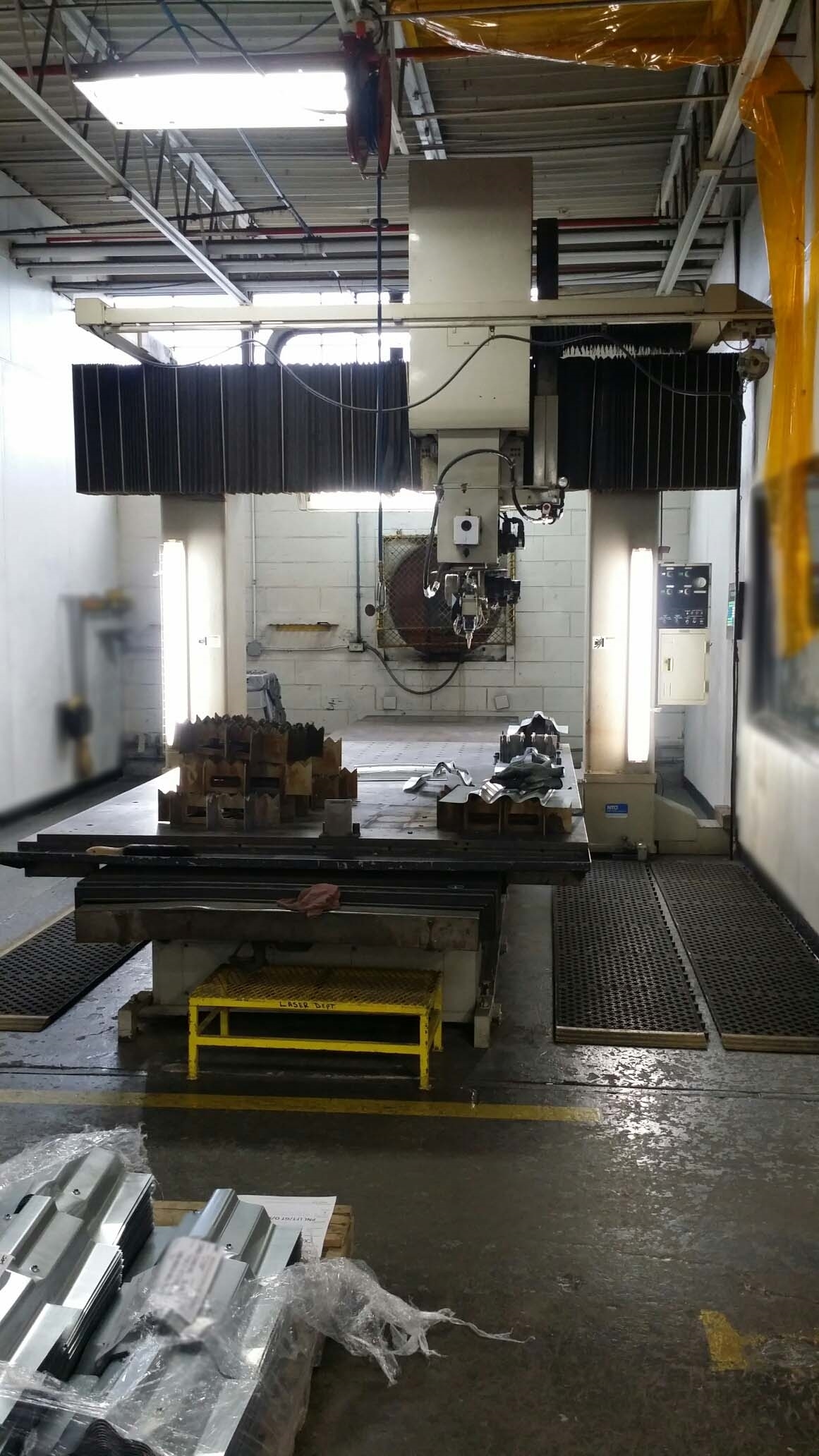

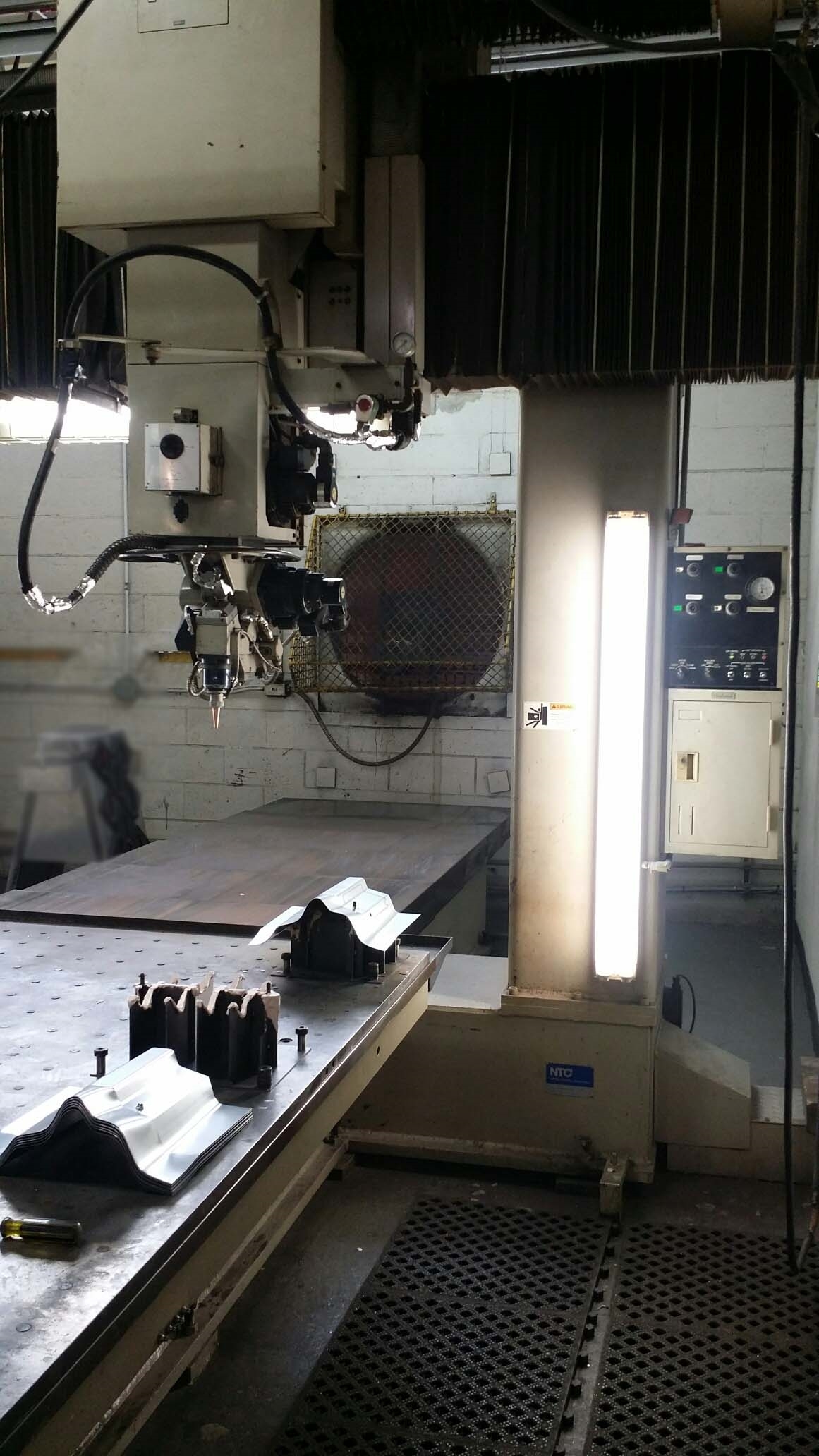

Used NTC 610 #9078734 for sale

URL successfully copied!

Tap to zoom

ID: 9078734

Laser cutting system

5-Axis

Table size: 75" x 122"

Table height: 27.5"

X-Axis stroke: 122"

Table left / Right travel

Y-Axis stroke: 75"

Optical head front / Back travel

Z-Axis stroke: 31"

Optical head front / Back travel

C-Axis: ±200° Optical head

A-Axis: ±180° Optical head

X, Y-Axis: 1378" / Min

Z-Axis: 1181" / Min

C, A-Axis: 15 mm / Sec

X, Y, Z-Axis: 1.2" - 1181" / Min

C, A-axis maximum: 200° / Sec

AC Servo drive motor

Drive mechanism ball screw

Guide mechanism linear ball guide

Positioning accuracy: ±0.04 mm (0.0016") / 300 mm (12")

Floor space: 168" x 308".

NTC 610 is a technologically advanced crystal growing, sawing and slicing equipment designed to grow, cut and slice large crystals with extreme precision. It is a turn-key system that can be used by various industries, such as optoelectronic, photovoltaic and medical, to reliably produce high-quality crystals with low levels of stress. The unit includes a robust platform and provides a crystal growth vessel, a linear slicing machine, a high-resolution sawing tool, and a real-time monitoring asset. The crystal growth vessel is designed to optimize growth conditions for high-purity ingots. It uses a finely-controlled environment, such as a low gas background pressure, temperature, oxygen content and growth rate. The crystal growth vessel isequipped with an adjustable magnetic field to control growth rates and direction and a high-intensity UV light source to accelerate the growth of crystals. The linear slicing model enables fast and precision-controlled slicing of large and complex geometry crystals. It is equipped with a wide range of precision tools, including linear blades, diamond wire cutting, polishing tools and laser cutting tools. It enables thin slices to be cut with minimal stress induced to the crystal. The high-resolution sawing equipment is designed to maximize cutting precision and accuracy. It is equipped with high-precision blades and a high-resolution sawing wheel for multidirectional slicing. The sawing wheel can cut up to 3mm thick slices in the x and y axis and up to 30mm in the z-axis. The real-time monitoring system provides accurate information about the crystal growth process. It records temperature, pressure and oxygen level data, which is used for analyzing crystal growth and for automating high-precision slicing and sawing. 610 unit is designed to provide optimal crystal production in a wide variety of industries and applications. It is a reliable and efficient machine that is equipped with the latest technology and features, making it ideal for producing high-quality crystals.

There are no reviews yet