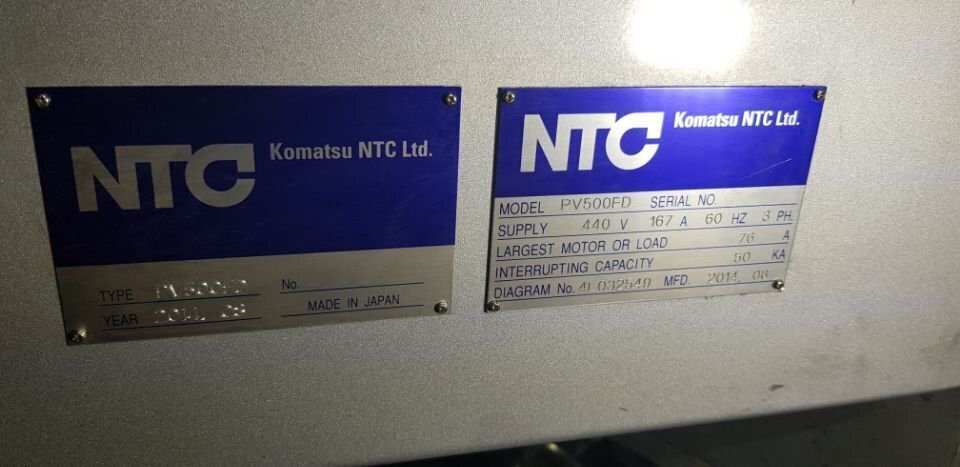

Used NTC / KOMATSU PV500FD #9216984 for sale

URL successfully copied!

Tap to zoom

ID: 9216984

Vintage: 2014

Diamond wire saw

Wire running method:

Coolant (Diamond wire): Acceleration / Deceleration 3 sec, (2) cycles/min

Slurry:

Two way / One way (Wire speed: 900 m/min / Slower)

One-way (Wire speed: Faster than 900 m/min)

Acceleration / Deceleration: 3 sec, (2) cycles/min

Wire speed (Maximum):

1200 m/min Coolant (Diamond wire)

1000 m/min (Slurry)

Cutting method (Feed): Downward cut

Cutting feed speed (Feed): 0.1 - 2.5 mm/min

Rapid feed / Rapid return speed (Feed): 50 - 500 mm/min

Wire storage capacity: 100 km

Core wire diameter: Φ 0.12 mm

Abrasive grain diameter: 10/20 µm

Wire diameter: Φ 0.15 mm

Wire tension: 25 N

Noise level: 80 dB (A) / Less

Compressed air (Dry air):

Air pressure: 0.4 - 0.6 MPa

Air capacity: 600 NL/min

Pipe size: Rc1/2 / Greater

Cooling water:

Cooling water temperature: 11 ± 1°C

Cooling water pressure: 0.35 - 0.40 MPa

Cooling water flow rate:

250 L/min (Supply to heat exchanger)

10 L/min (Cooling main spindles)

Cutting fluid:

Slurry:

Use slurry: 170 mPas / Below

SC1000 (Viscosity 100 - 150 mPa.s)

Coolant (Diamond wire):

Stock solution

Water-dilution: SUNDASH Series (Nicca chemical)

Mist exhaust: Recommended exhaust capacity 3 - 5 m³/min

Piping and primary power cable inlet: Overhead

Automatic coolant change unit:

Supply: 40 A

Discharge: 40 A

Feed unit:

Stroke: 355 mm

Cutting feed speed: 0.1 - 2.5 mm/min

Rapid feed speed: 50 - 500 mm/min

Motor output:

0.75 kW With brake (AC Servomotor)

With 1-25 reduction gear

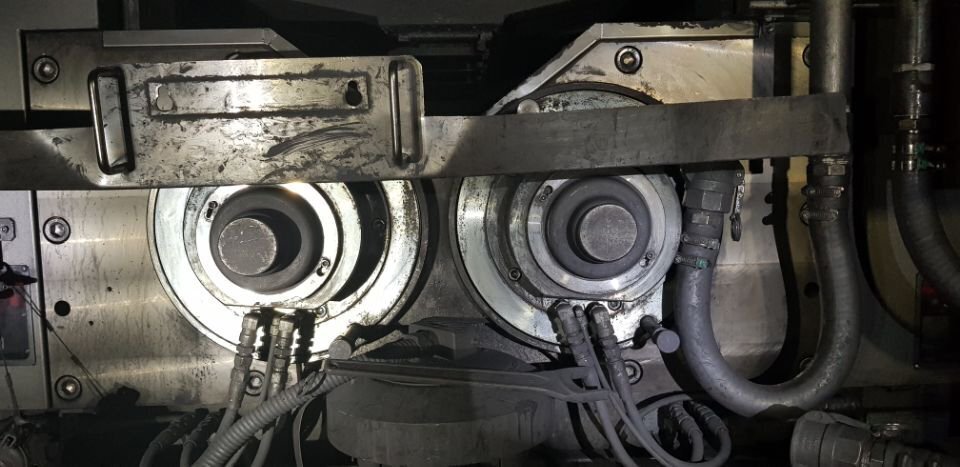

Main roller:

Groove outer diameter (Usable range): Φ240 - Φ230

(2) Main spindlers:

Motor output: 60 kW (AC Servomotor)

Rated motor torque: 500 Nm

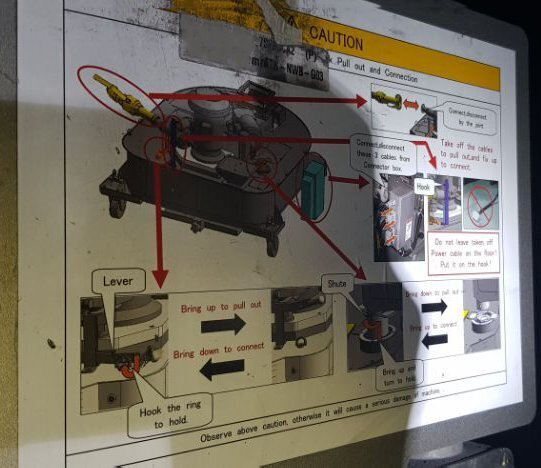

(2) Reel spindlers / Traverse:

Motor output: 16 kW (AC Servomotor)

(2) Dancer rollers:

Wire tension: 10 to 25 N

Motor output: 5.5 kW With brake (AC Servomotor)

(6) Guide rollers:

Roller groove diameter: 100 mm

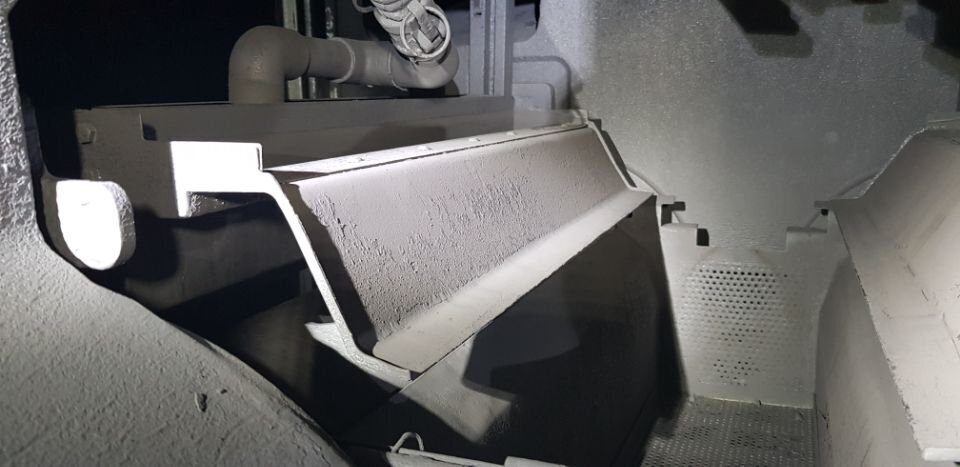

Coolant tank unit:

Tank capacity: 400 L

Coolant supply pump output: 7.5 kW

Agitator motor: 0.75 kW

Fluid level detection: Float type

Heat exchanger:

Method: Cooling water control, (2) paths

Heat exchanger duty: 90 kW (77400 k cal)

Lubrication:

Grease:

Main spindles

Reel spindles

Feed ball screw

Traverses

Hydraulic unit: Tank capacity 1.4 L

Control power source: 100 VAC, 24 VDC

Electric power capacity:

Machine: 74 kVA (Maximum: 125 kVA)

Primary power source: 380 VAC, 50 Hz / 440 VAC, 60 Hz, 3-Phase, 3-Wire

Voltage fluctuation: ±10%

Frequency fluctuation: ±1 Hz

2014 vintage.

NTC / KOMATSU PV500FD is a comprehensive crystal growing, sawing and slicing equipment that is designed for the efficient production of materials, including silicon for integrated circuits. It is equipped with a pulse-heated chemical vapor deposition (CVD) synthesis system, a high-precision wire saw slicing unit and other advanced components. This makes it ideal for high-quality bulk crystal growth in a wide range of materials, applications and specifications. The CVD synthesis machine includes a high-temperature pulse-heated susceptor furnace with a capacity of up to 250 mm. It is capable of reaching high temperatures of up to 2000°C. It can also be used for compound semiconductor growth and the chemical vapor deposition of diamond films. The furnace features an auto-tilt and a slave sys tem for precise setting and improved temperature uniformity. The high-precision diamond wire saw slicing tool is used for slicing single crystals. It is equipped with a variable-speed direct-drive servo motor, auto-feed and tracking speed control. Its split-type cutting sequence and automatic slicing option improves the yield rate. The rigidly-structured reversing wire saw can be loaded with up to six slots, and it can be also used for multiple sawing operations. NTC PV500FD is capable of performing multi-stage slicing with precision diamond blades. The slicing function has the ability to adjust the blade size, cutting speed, cutting direction and slice profile. It also offers the ability to store up to 50 different slicing recipes. KOMATSU PV500FD asset is also equipped with a robot-operated multi-bin, conveying and sorting model for sorting pieces after they have been sliced. The equipment can be customised to fit user's requirements and can be operated in continuous or batch mode. The system is designed to minimise power consumption and reduce costs. It features an energy-saving recovery and tempering unit for the heating machine and an active temperature control for improved energy efficiency. It also includes a monitor to detect abnormal conditions in the tool. PV500FD is a comprehensive asset for the efficient production of materials required for various applications, including silicon for integrated circuits. It is equipped with a pulse-heated CVD synthesis model, a high-precision diamond wire saw slicing equipment, a cutting and slicing robot, and a multi-bin sorting system for sorting pieces after slicing. The unit is designed to operate at maximum efficiency to minimise power consumption and reduce costs.

There are no reviews yet