Used NTC / KOMATSU PV500FD #9316437 for sale

URL successfully copied!

Tap to zoom

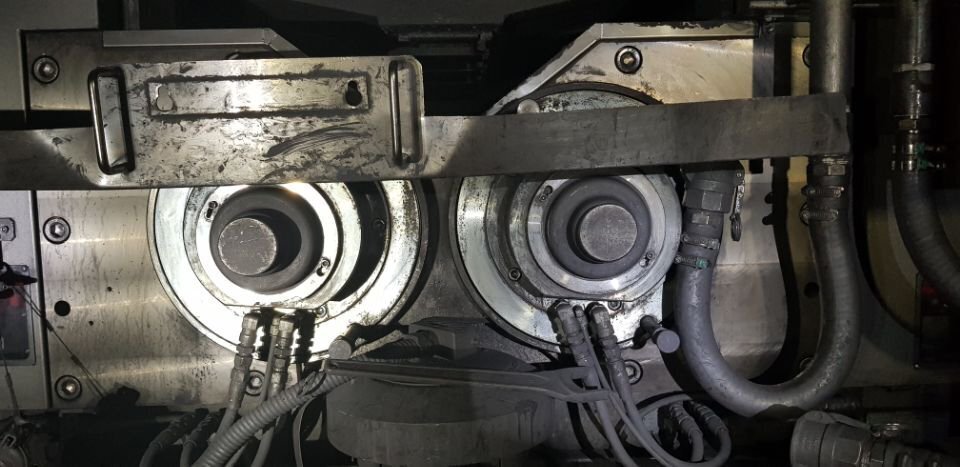

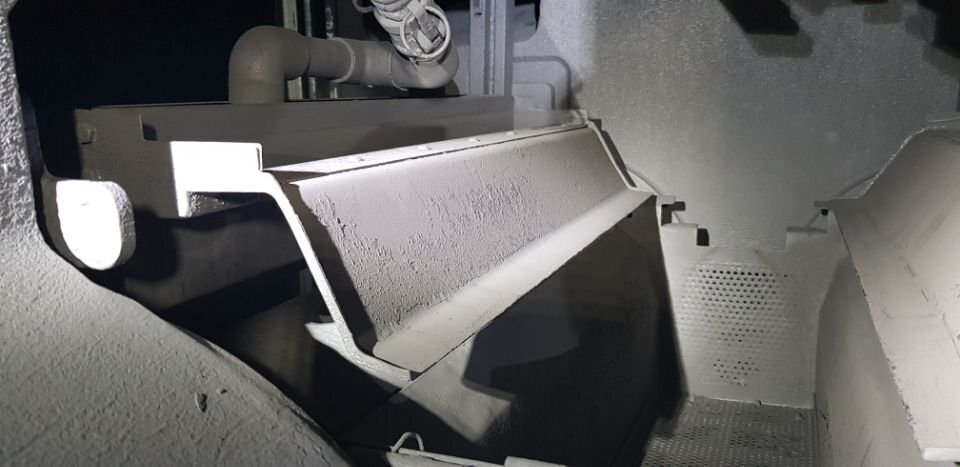

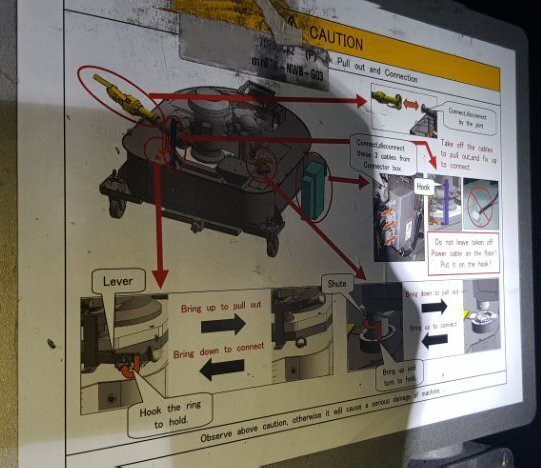

NTC / KOMATSU PV500FD is a crystal growing, sawing and slicing system developed for the efficient growth, processing and analysis of various types of crystals. It is especially designed for the growth and related processing of thin and bulk crystals such as silicon single crystal. NTC PV500FD consists of a single NTC Crystal Grown Unit (CGU) and several cutting tools. The CGU is a specialized thermal chamber equipped with a special high-pressure, high-temperature susceptor to generate Czochralski (CZ) or Floating Zone (FZ) grown crystal at its center. The tailoring of the thermal field can provide a very quickly and highly uniform temperature distribution throughout the chamber. This significantly reduces the non-uniformity of the crystal growth. The saw is a fully automated diamond wire saw arranged at the center of the CGU. It is capable of slabbing bulk crystals into thin and uniform slices with a minimum inter-slice spacing of 5 micrometers and with cutting speeds ranging from 30 to 300 mm/sec. It is controllable accurately by a step-motor and features a rough programmable cutting function. The slicing and lapping equipment consists of a linear-drive belt-based slicing/polishing machine and a precision parallel slicing saw. Each of these offers a slicing speed of 30 to 50 mm/sec, depending on the crystal material, as well as a repeatable surface finish and a system for controlling and adjusting cutting axis. They also allow for the accurate slicing of near-net-shape crystal discs with minimal material loss. The crystal surface analyze is powered by KOMATSU advanced mirror-finish surface detectors, which can be used to accurately monitor and control the overall surface condition. This allows for the measurement of the surface finish, the discrepancies in the origin orientation, and the surface microstructure. In conclusion, KOMATSU PV500FD is a highly advanced crystal growing, sawing and slicing system. It provides quick yet precise and uniform growth, cutting, and slicing of a variety of crystals types and sizes, and the crystal surface analysis ensures the highest quality for the finished product.

There are no reviews yet