Used NTC / KOMATSU PV500FD #9316449 for sale

URL successfully copied!

Tap to zoom

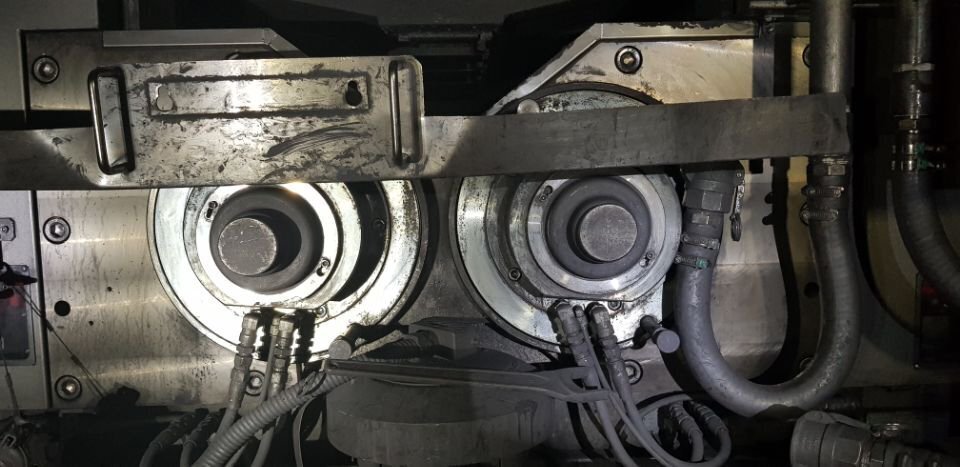

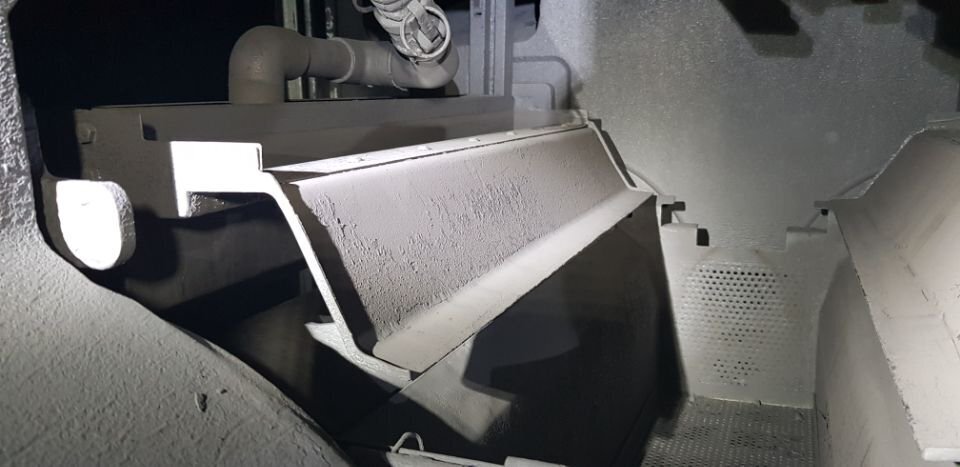

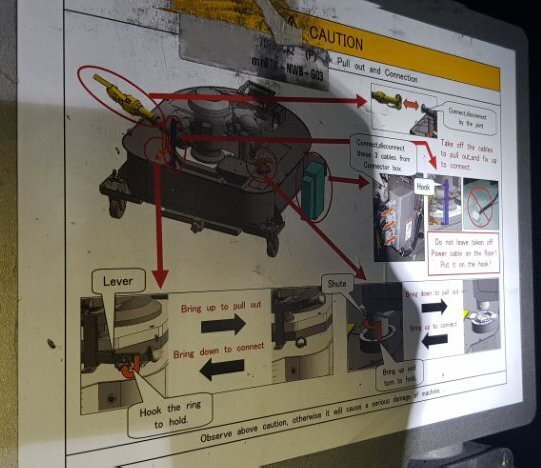

NTC / KOMATSU PV500FD is a fully automated single-crystal growing, sawing, and slicing equipment designed for the superior performance of semiconductor production. Its multifunctional design allows for fast and precise cutting of single-crystal wafers with a diamond saw blade. NTC PV500FD utilizes a gas-driven core to precisely confirm the height and diameter of the crystal growth substrates. This feature ensures maximum crystal growth yields with the greatest predictability. The temperature control of the system is designed to constantly monitor and adjust the core temperature to stabilize the crystal growth process. Throughout the growth process, oxygen is introduced into the core to act as a catalyst for the crystallization process. This technological advances leads to an increase in crystal yield, efficiency, and uniformity. KOMATSU PV500FD also employs a single-arm serial sawing unit and can be programmed to saw in a straight or rotary pattern. The saw slurry is filtered and immobilized to ensure accuracy and quality for the most translucent single-crystal wafers. After the crystal has been grown, the machine can then be used to slice crystal plates. This is accomplished through the use of a high-accuracy optical interferometer. This allows for cutting of up to 0.8mm thick substrates without deformation of the substrates. To ensure quality of crystal production, PV500FD utilizes a process monitoring tool that can automatically detect any irregularities in the process. This helps to maintain the highest quality crystals and optimize overall growth efficiency. NTC / KOMATSU PV500FD is a revolution in the field of crystal growing, sawing, and slicing. Its precise control of the crystal growth environment, innovative process monitoring asset, and high accuracy sawing model make it an invaluable tool for semiconductor production.

There are no reviews yet