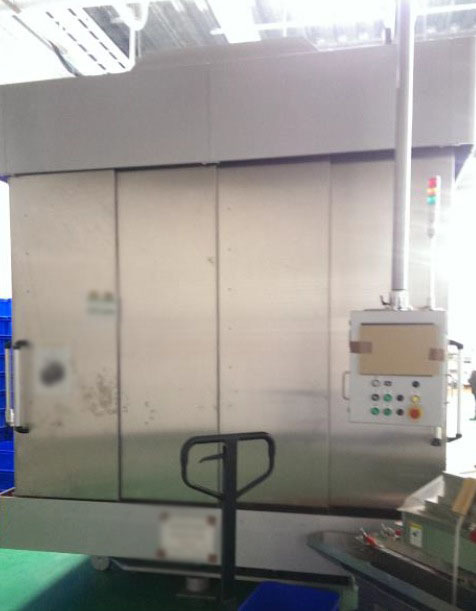

Used NTC MBS1000C #9066477 for sale

URL successfully copied!

Tap to zoom

ID: 9066477

Crystal Growing, Sawing & Sawing Systems

Includes:

(2) Mainframes of MBX100C

Electrical control box (transformers, power cores, etc.)

Control panel

Control box (PLC, etc.)

Electric stacker and charger

Lifting car

Parts

Main motor: (4) pieces

Maximum Wire speed: 1,00m/min

Maximum Wire up capacity: φ0.25mm x150km

Cutting feed speed: 0.02~2.5m/min

Slurry tank capacity: 400Lit

Power supply in use: 200V± 10% .50Hz

Power Consumpiton :102KAV (MAX 116KVA)

Maximum workpiece dimension:

φ165xH500x25 pieces (for 156))

φ210xH500x16 pieces (for 156)

890xH500x25 pieces (for 156)

1,060xH500x36 pieces (for 156)

2010 vintage.

NTC MBS1000C is an innovative crystal growing, sawing and slicing equipment designed to help researchers rapidly grow large, high quality crystals in a laboratory setting. It uses a patented combination of a vacuum sealed chamber, heating and cooling elements, and precisely tuned motors to grow and manipulate the crystal. MBS1000C consists of multiple subsystems. The vacuum chamber is the most essential component, as it is able to hold the necessary pressure to grow high-quality single crystals, while allowing for uniform temperatures and very little interference from ambient conditions. The unit is powered by a three-phase motor that runs at a range of speeds, allowing for precise control of the crystal's growth rate during the manufacturing process. Temperature control is achieved via two unique systems. The first is a conventional heating and cooling element which helps keep the chamber at the desired temperature. The second is a unique cooling system which employs thermal conductivity to keep temperatures precisely calibrated. This unit is particularly effective for growing large crystals. The sawing and slicing of crystals is accomplished using a precisely timed motor-driven machine arm, which moves the cutting head in a continuous loop over the crystal. This helps prevent chipping and cracking during the slicing process while allowing for an extremely precise and uniform slicing angle. This machine, combined with the integrated optical microscope and pneumatic lift capability, enables researchers to achieve high levels of precision in the final product. Lastly, an advanced computer-based control tool is built into NTC MBS1000C, allowing for researchers to customize the entire crystal growth process and monitor parameters such as temperature, pressure, and growth rate. The intuitive user interface makes the machine easy to learn, and the high precision technologies in the asset make it ideal for professional crystal growers looking for the highest quality results.

There are no reviews yet