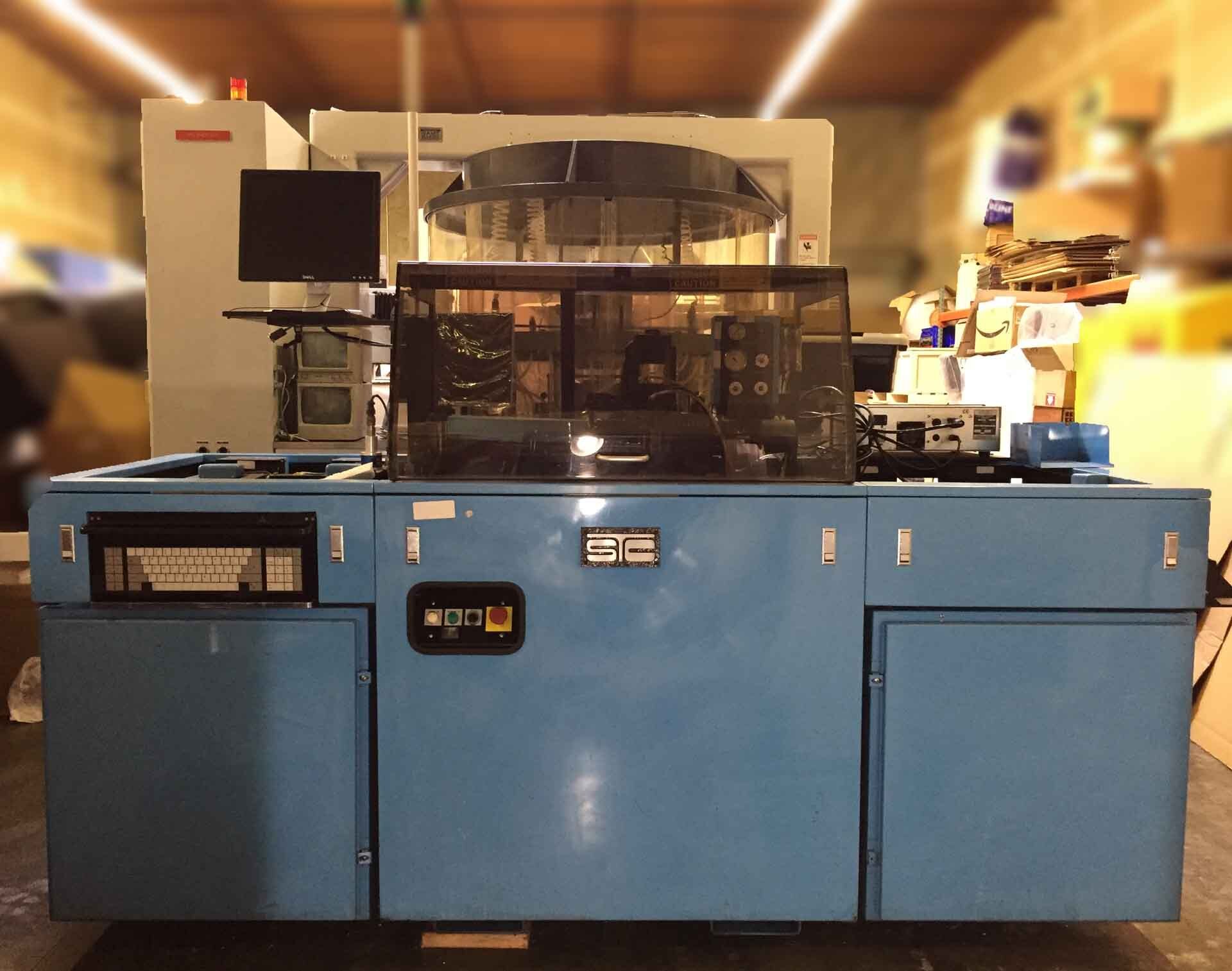

Used STC EP 2600 #293667226 for sale

URL successfully copied!

Tap to zoom

ID: 293667226

Wafer Size: 2"-6"

Vintage: 2000

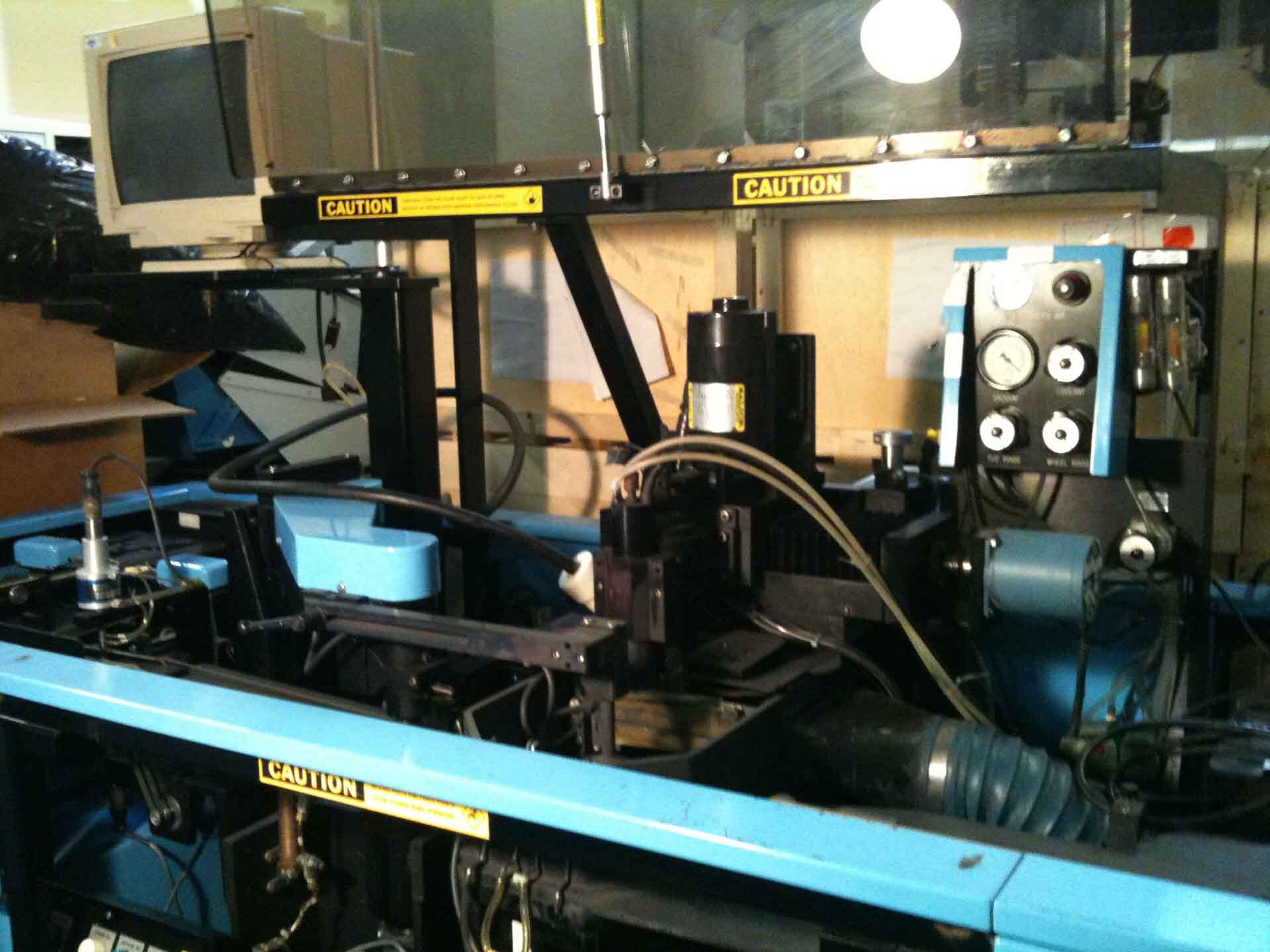

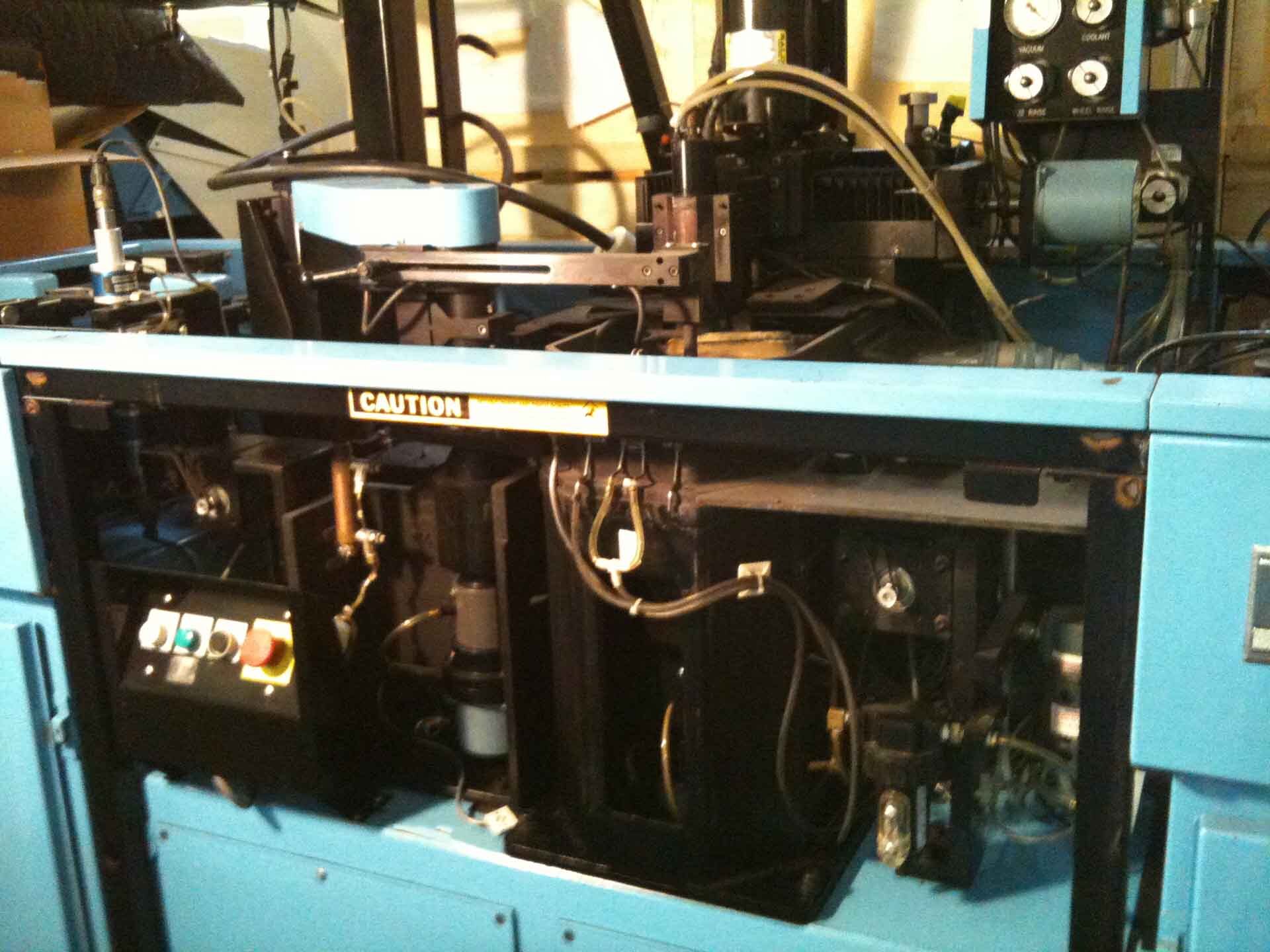

Edge grinder, 2"-6"

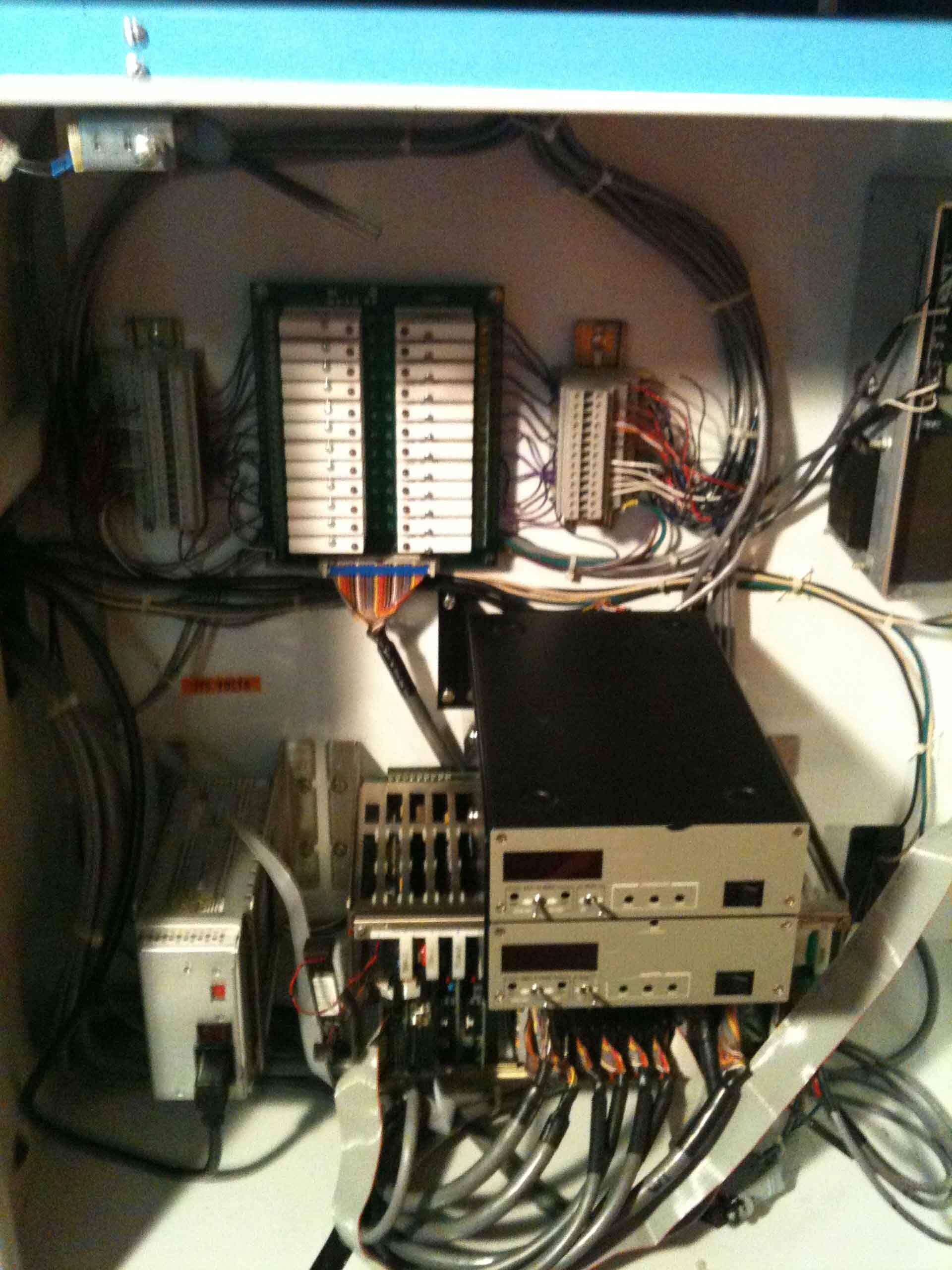

Precise adjustable frequency converter spindle controller

Precise coolant circulation system for liquid cooled spindles

Power: 220 V

2000 vintage.

STC EP 2600 crystal growing, sawing, and slicing equipment is a fully automated unit designed for research and small production operations that offers a high quality, reliable solution for crystal growth, cutting, and slicing. The system is easy to use and can be operated by non-experts with minimal training. The complete unit includes a cutter for sawing bulk crystal into slices, a growth chamber for growing single crystals, an assembly for slicing and dicing the grown crystals into smaller blocks, and a polisher for polishing each block. The growth chamber contains a high-intensity light source, liquid-nitrogen cooled copper block, and removable gas control machine. This allows for growth of single crystals with very low impurity levels and precise specifications. The crystal starts in the growth chamber and is then transferred to the cutting station. Here, the crystal is positioned in a chamber that uses a flexible, diamond-tipped blade to saw the crystal into thin slices. The thickness of the slices can be controlled through adjustable water pressure levels, which can be finely tuned to get the best possible performance. The crystal slicing assembly then uses a series of slicing heads to precisely cut the slices into blocks that can be as small as 0.5mm in thickness. Each head is equipped with its own adjustable motor for providing consistent-sized blocks, and the motors are linked to an adjustable counter-weight tool for accurately positioning the crystal for each cut. Finally, the blocks are polished to remove surface imperfection and create a finished product that is ideal for use in research and production. EP 2600 crystal growing, sawing, and slicing asset is a versatile tool that offers a reliable, high-quality solution for crystal growth, cutting, and slicing. The model is easy to use and maintain, and its fully automated design ensures a consistently high product yield without requiring extensive expertise from the user. With the ability to produce thin slices and polished blocks to precise specifications, this equipment provides a reliable solution for research, industrial production, and commercial applications.

There are no reviews yet