Used ASM AD 809-06 #9284935 for sale

URL successfully copied!

Tap to zoom

ID: 9284935

Die bonder

Vacuum: 50 cm-Hg

Compressed air supply: 4 bar

Die size: 0.2 mm - 1.5 mm

Rotary arm: Dual arm system

Bonding collet: Surface pick type

Bond force: 40 g - 200 g

Cycle time: 600 m-sec

System accuracy: XY (±0.05mm);¢ (±3º)

Wafer stage XY table:

Maximum travel: 6" x 6" (153mm x 153mm)

Resolution: 7.62 µm

Repeatability: ±5.08 µm

PCB XY Table:

Travel area: 4" x 8" (101mm ~ 203mm)

Resolution: 7.62 µm

Repeatability: ±5.08 µm

Memory capacity:

(64) PCB

Number of bond point per PCB: 350

PCB Dimension:

Maximum: 4" x 8" (101 mm x 203 mm)

Minimum: 1" x 0.47" (25 mm x 12 mm)

Pin length: 0.79" (20 mm)

Power: 110/220 VAC, 1.7kW, 50/60 Hz.

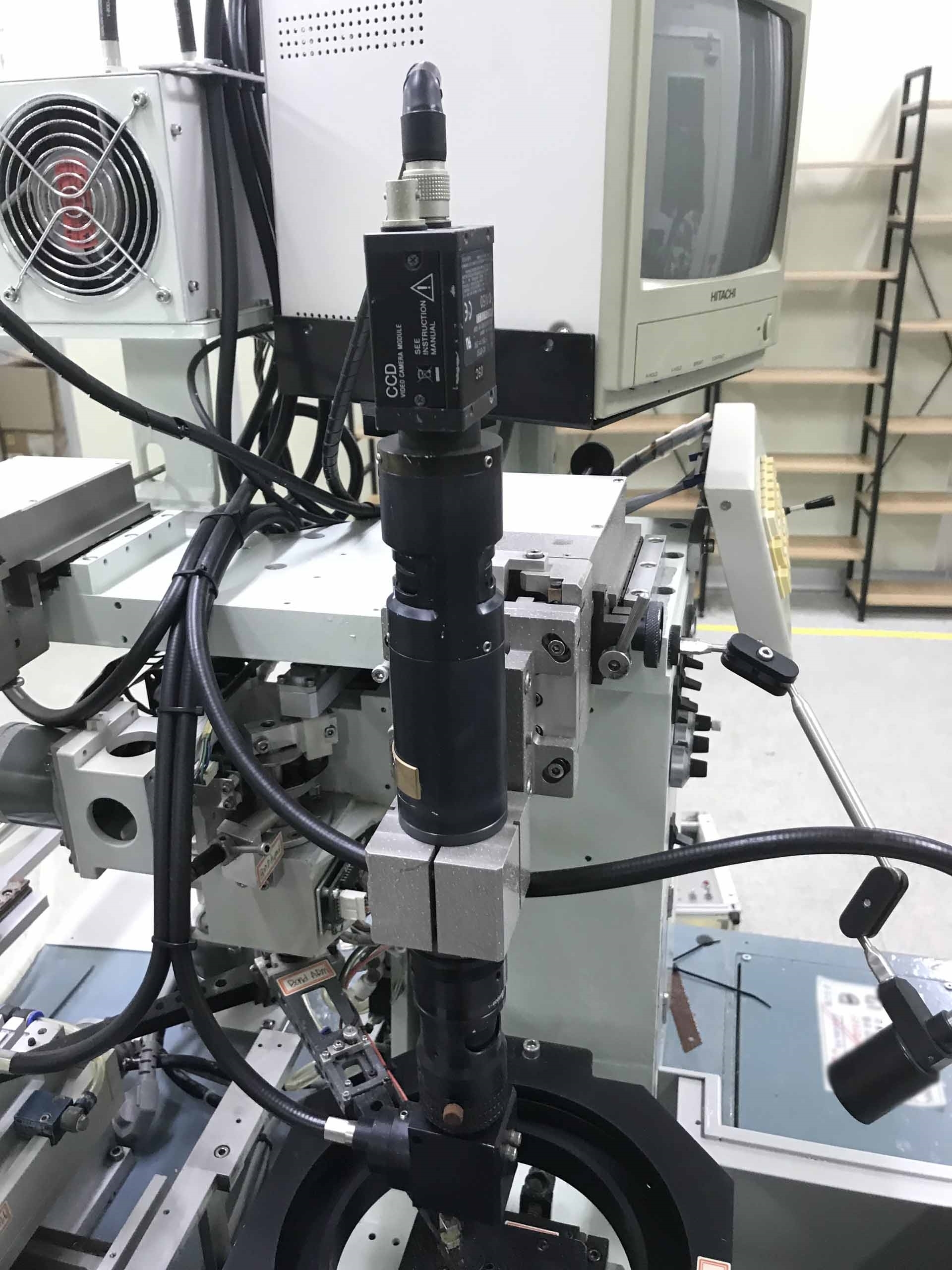

ASM AD 809-06 is an automated die attacher used in the electronics industry. This particular model is a de-bossing type die attacher and is used to attach dies to a variety of printed circuit boards. AD 809-06 has a CCD camera that is used to scan and identify the board position, as well as align the dies to attach to the board for an accurate attachment. ASM AD 809-06 has a wide range of features that make it a useful tool for any electronics industry. First, it has a durable construction and is designed to be antistatic with ESD protection. This ensures that the machine will not attract dust, dirt, or other contaminants and keeps the board safe from any electrical shock. AD 809-06 also provides a high level of accuracy, with a tolerance range of 0.1 mm, which ensures that each die is correctly attached. There is also the ability to select the pressure settings which can be adjusted depending on the material that is being attached. ASM AD 809-06 has a large work table, which allows for the biggest of jobs to be completed with accuracy and speed. The table is a modular design, allowing for flexibility and versatility in the job that needs to be done. This machine is equipped with a high torque motor coupled with an advanced control system. This allows it to attain high speeds and maintain precision. In addition to its ability to accurately and quickly attach dies, AD 809-06 also offers a variety of safety features. These include an emergency stop button which stops the machine when pushed, and a detection system that completely shuts down the machine if an object enters the area that is not meant to be attached. This ensures that no accidental damage is caused to the board or machine when operating. In conclusion, ASM AD 809-06 is an excellent automated die attacher perfect for any application in the electronics industry. With its strong durability, accuracy, speed, and safety features, this machine is guaranteed to make short work of any task it is tasked with.

There are no reviews yet