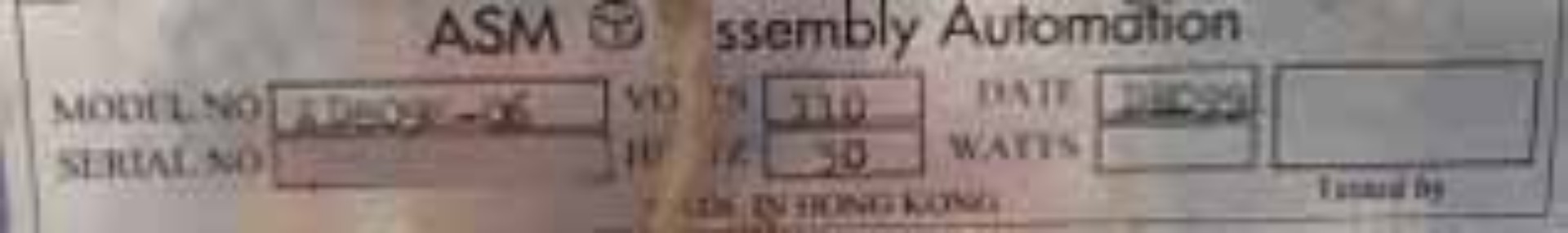

Used ASM AD 809 #9217965 for sale

URL successfully copied!

Tap to zoom

ASM AD 809 is a die attacher that is used for the precision attachment of multiple types of die and substrates. It is the ultimate versatile tool for semiconductor and packaging assembly. ASM AD809 uses a patented pick-and-place and vacuum-assisted attachment technology to provide precise, high-speed die attachment. It can attach die to a variety of substrates such as FR-4, ceramic, and metal. It also has the capability of accommodating larger dies by utilizing solder preforms or flux application. AD-809 is designed to handle high-volume production needs with speeds up to 20,000 die attachments per hour. AD809 is driven by an Ethernet-based equipment with accessories that can be integrated. It includes several features that make it appropriate for precision die attach operations, such as temperature control, force control, and a vision system for accurate placement. The unit is also compatible with a range of robotic interface systems, allowing for the external operation of its parts and accessories. AD 809 also supports module exchange, where any individual module can be replaced or upgraded for increased productivity. ASM AD-809 requires minimal setup and maintenance time, as well as low operational costs. It has an extremely efficient design that eliminates the need for excessive levels of oxygen or vacuum during die attachment. The machine also offers repeatable, accurate attachment thanks to its vision tool and pressure-sensing technology. ASM AD 809 has a high degree of mark accuracy, ensuring that die will attach securely in the right location and orientation. Overall, ASM AD809 die attach asset is a powerful solution for high-volume production needs. It has robust features and the ability to accommodate multiple die sizes, providing a flexible and versatile solution for sensitive and precise high-volume assemblies.

There are no reviews yet