Used ASM AD 809C #127757 for sale

URL successfully copied!

Tap to zoom

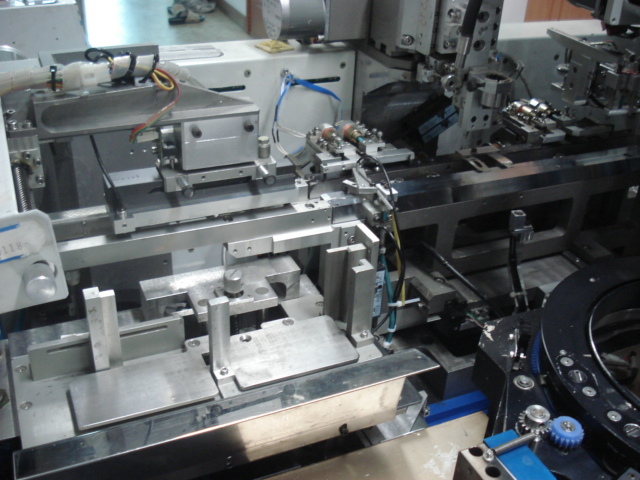

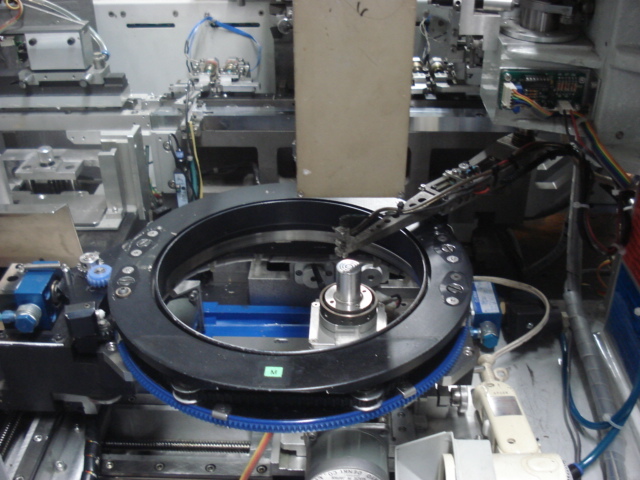

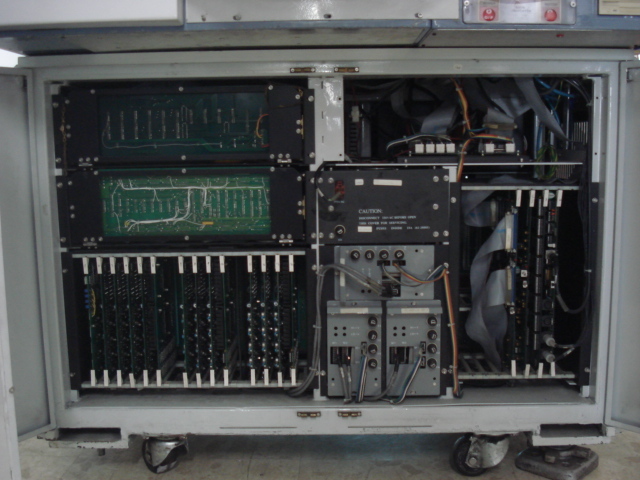

ASM AD 809C is an advanced die attach equipment designed for use in the manufacture of printed circuit boards. It is a compact and easy to use equipment that is capable of precisely handling and positioning tiny discrete components. This system allows for accurate placement of small components onto the printed circuit board in order to form an electrical connection. The unit features an automated vision machine that can easily recognize the exact position of the components as well as a high precision articulating head mechanism that is capable of reaching even the most inaccessible components. The feeder portion of the tool is equipped with a vibration dispensing unit that accurately portions out the required components and positions them onto a strip of adhesive tape. This improves placement accuracy which is essential when dealing with small components. Furthermore, the asset features a three stage heating and cooling model that provides safe and reliable die attach processes that are designed to maintain consistent quality between pre-bond and post-bond processes. In order to ensure consistent high quality operation, the equipment features a sophisticated control system with over 30 stored recipes that can be selected. This allows the user to quickly and easily change between various processes and device types. Furthermore, the unit monitors performance throughout the cycle and will automatically stop in the case of a die attach failure or if the process does not meet the programmed specifications. AD 809C also features an advanced monitoring machine that allows the user to keep track of all relevant information such as total snips, total die attach time, total programmed recipes, and total number of circuits processed. This allows for the quick identification of any issues that may affect process reliability. Additionally, the tool is equipped with an easy to read LCD that can be programmed to display the current process status or provide useful feedback information, such as cycle time, to the operator. All in all, ASM AD 809C is an easy to use die attach asset that can be used to precisely handle and position tiny discrete components. Its sophisticated control model, process monitoring equipment, and advanced vision system ensure consistent quality and reliable performance.

There are no reviews yet