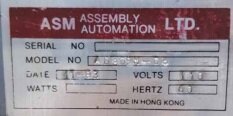

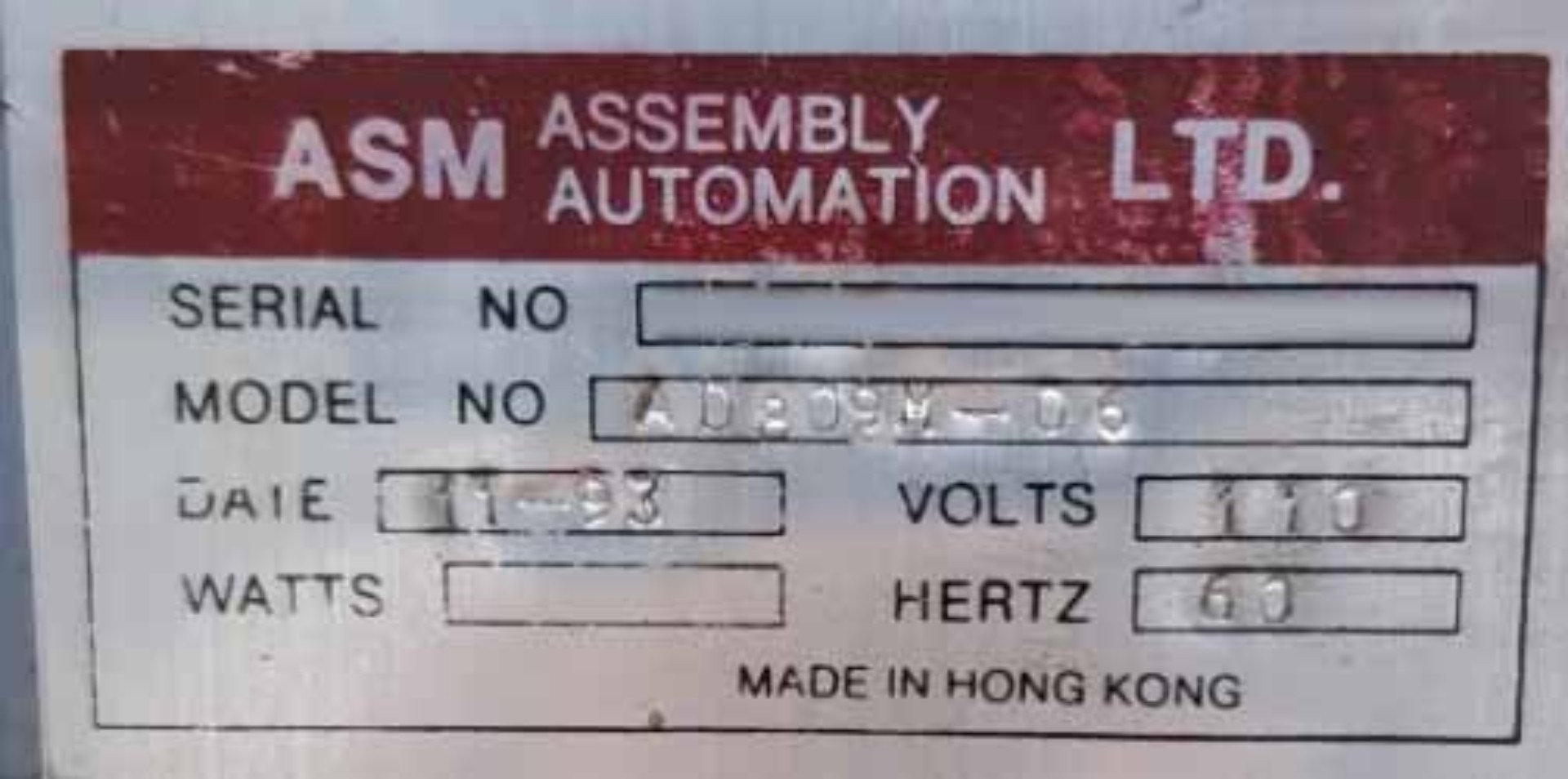

Used ASM AD 809M #9217966 for sale

URL successfully copied!

Tap to zoom

ASM AD 809M is a semi-automatic die attacher designed for use on long- and short-run production operations. It features a modular design that can be reconfigured for different die attachment applications, with an adjustable table height and fixture-lock clamps for a wide range of production sizes and shapes. This machine is able to attach dies at a rate of 30 to 40 parts per minute with very high accuracy and repeatability. AD 809M is equipped with a pneumatic remote control panel for simple operation. There is a die pallet interlock system that prevents start of the operating cycle if the die pallet is not locked correctly. It has two adjustable sensor systems for monitoring the accuracy of the die attachment process, and an adjustable die-detect switch to monitor accuracy of die placement. The machine is equipped with a CNC-like controller, allowing for detailed input/output programming and visualization of process parameters and tracking of changes at the die-attachment station. ASM AD 809M is designed for operation in hazardous areas. With a low system noise level, it is suitable for use in office environments. The machine is constructed with several safety features, including triple safety guards and a warning light system for hazardous motions. The sealed construction prevents infiltration of dust and other foreign matter, and it is designed to meet all safety standards. The machine has a small footprint, about 8' wide, 6' deep and 17' high, and is highly efficient with a small power consumption. AD 809M is ideal for a wide variety of die-attachment applications. It is easy to use, offers reliable performance, and requires minimal maintenance. With its advanced features and a host of safety features, it is the perfect die-attachment solution for companies looking to increase productivity while reducing operating costs.

There are no reviews yet