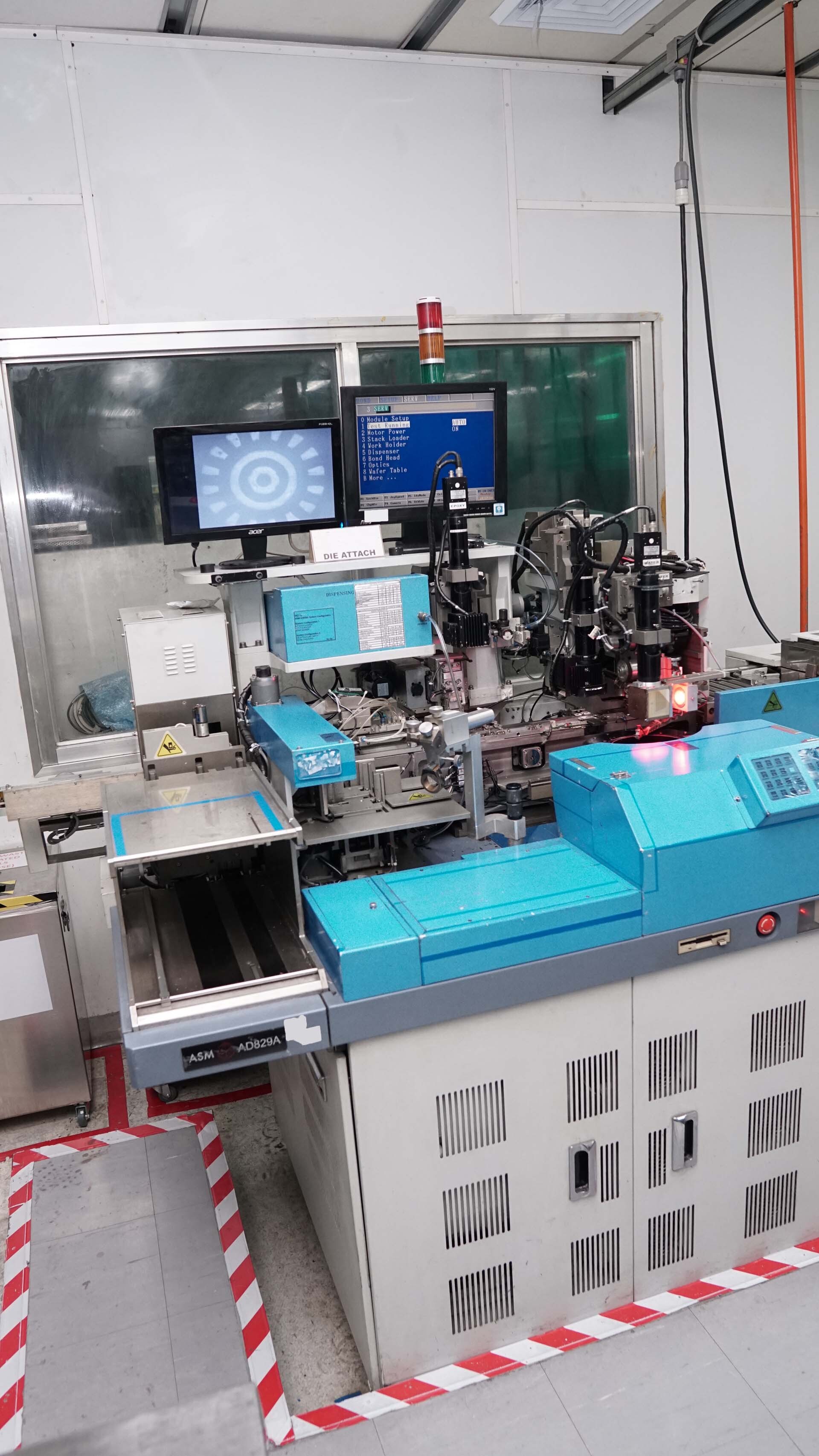

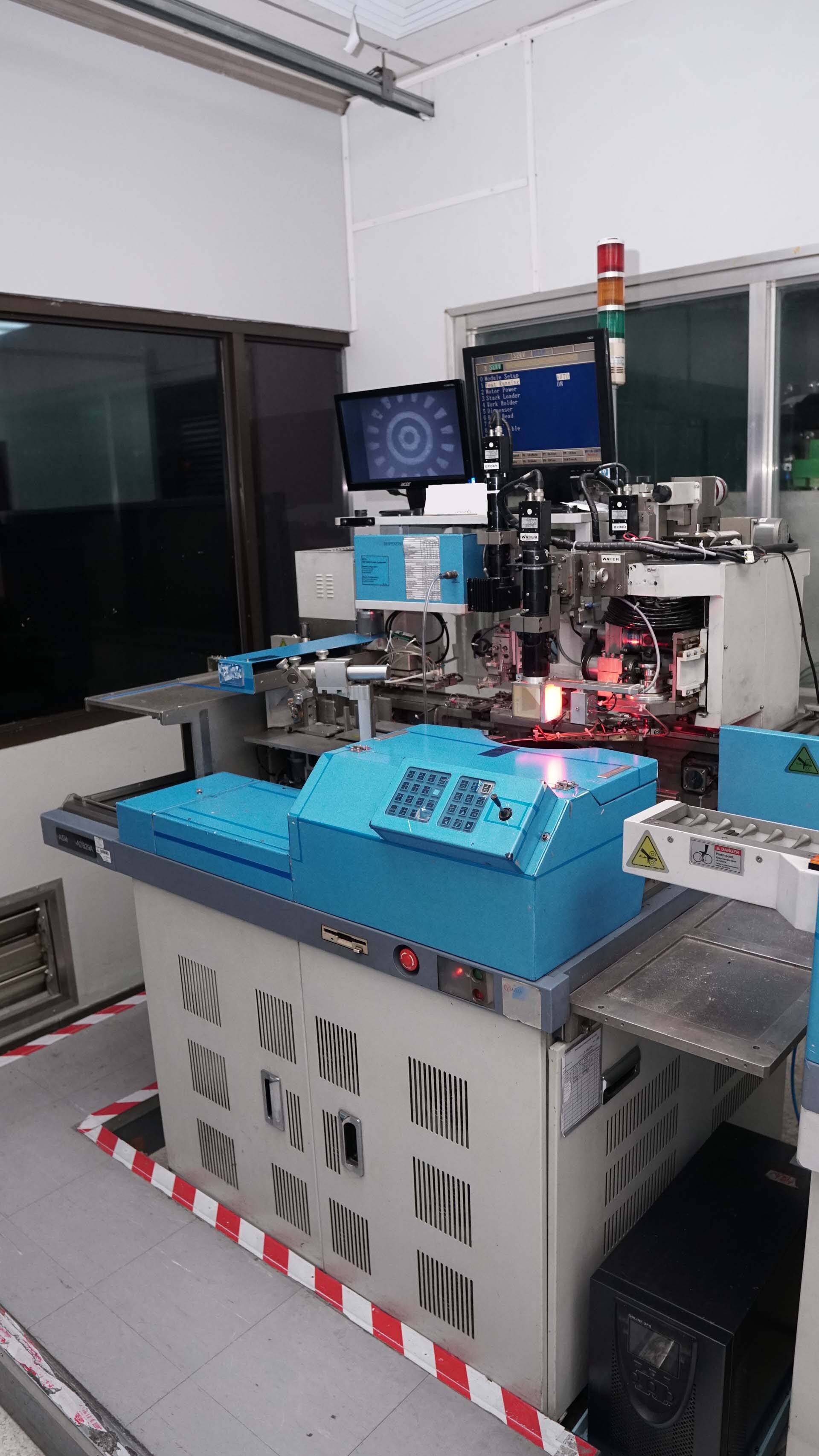

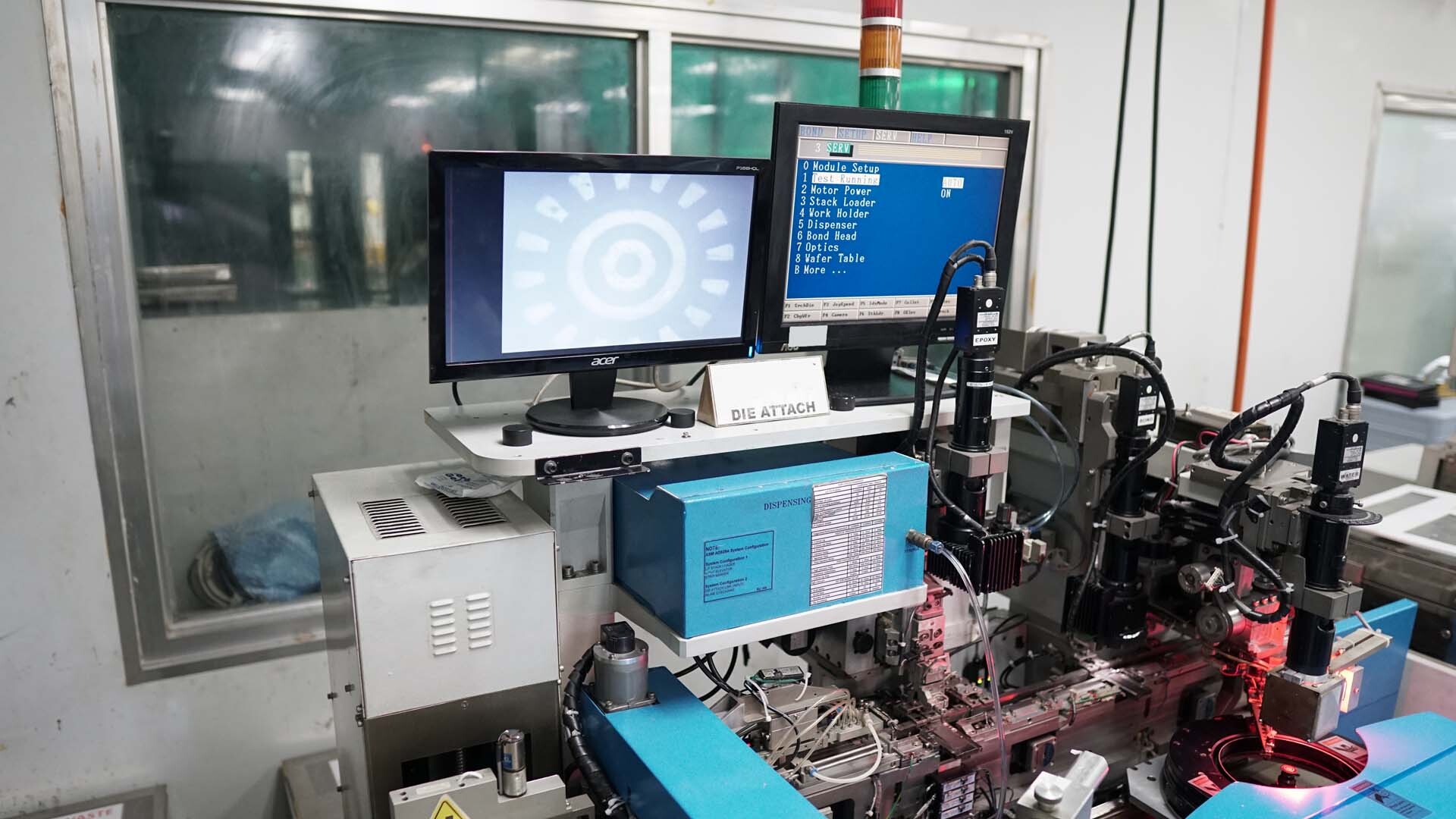

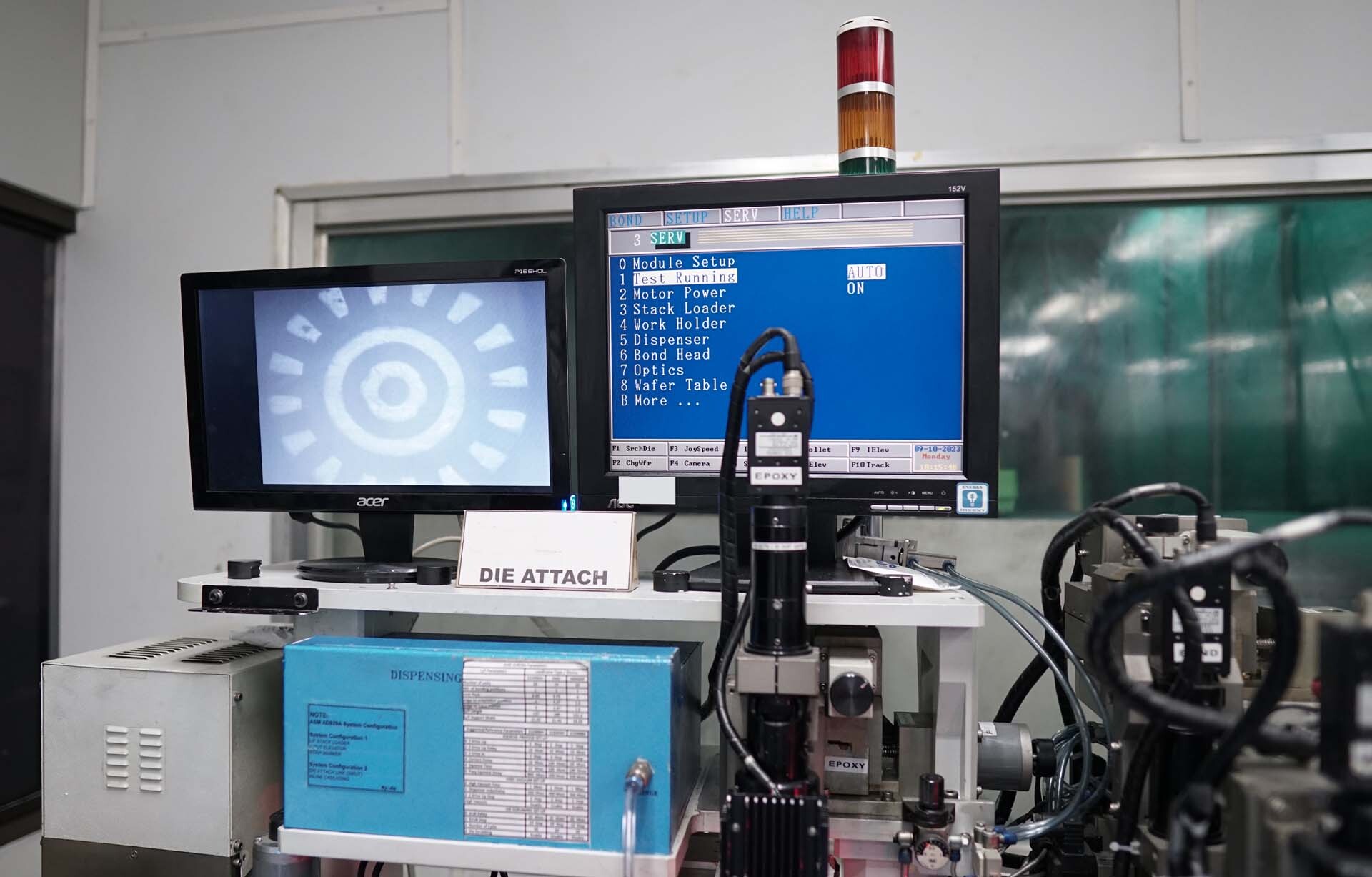

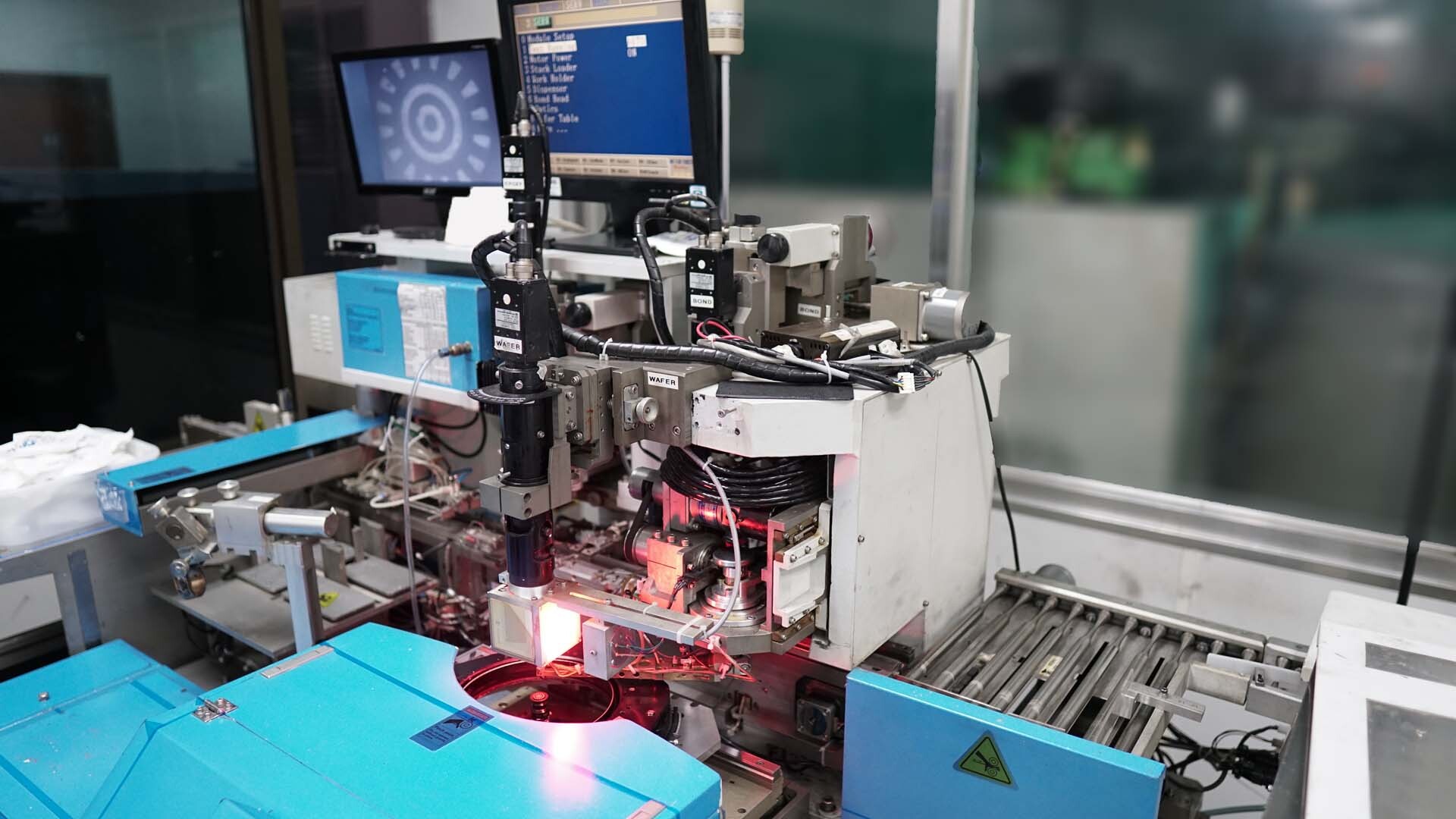

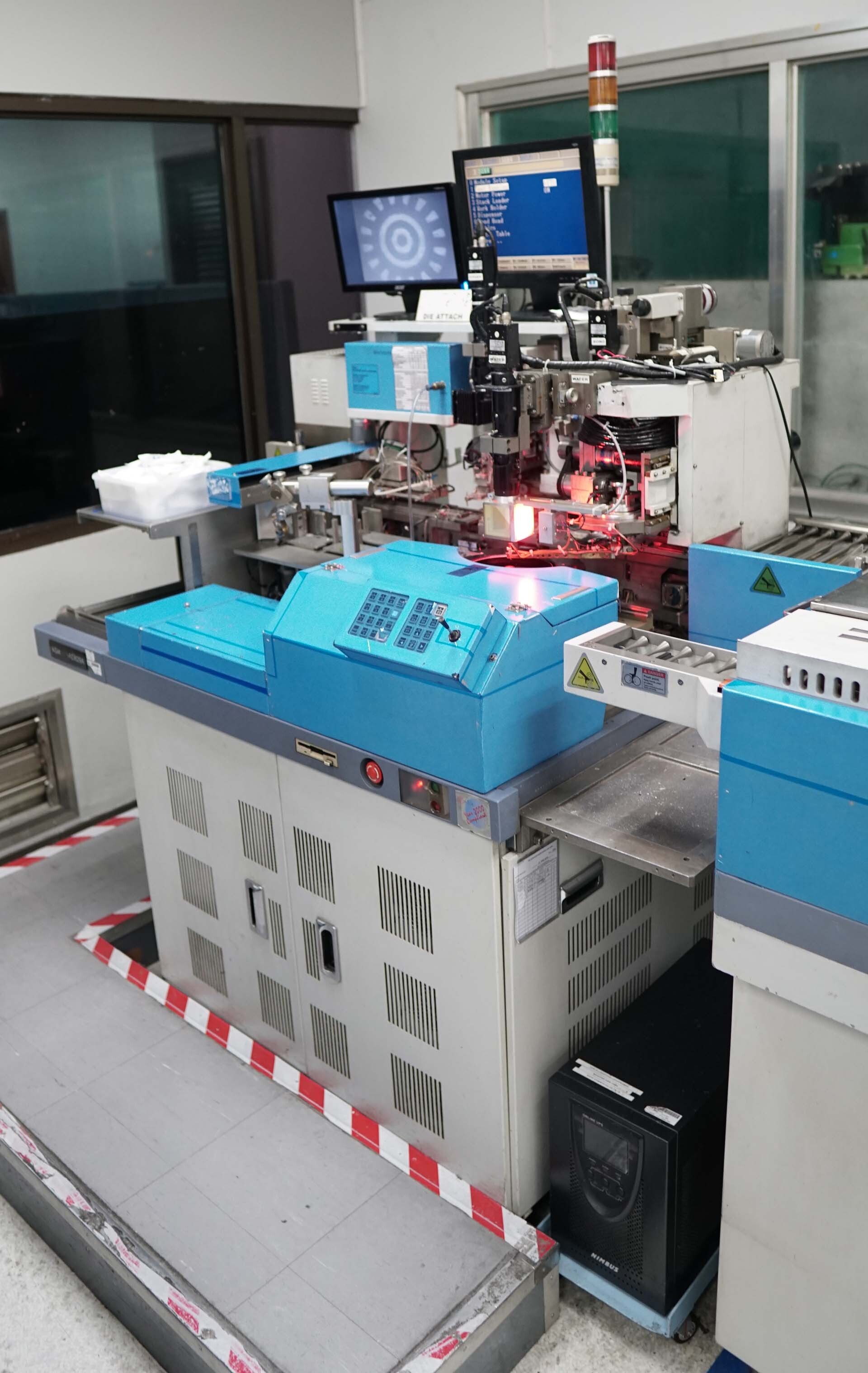

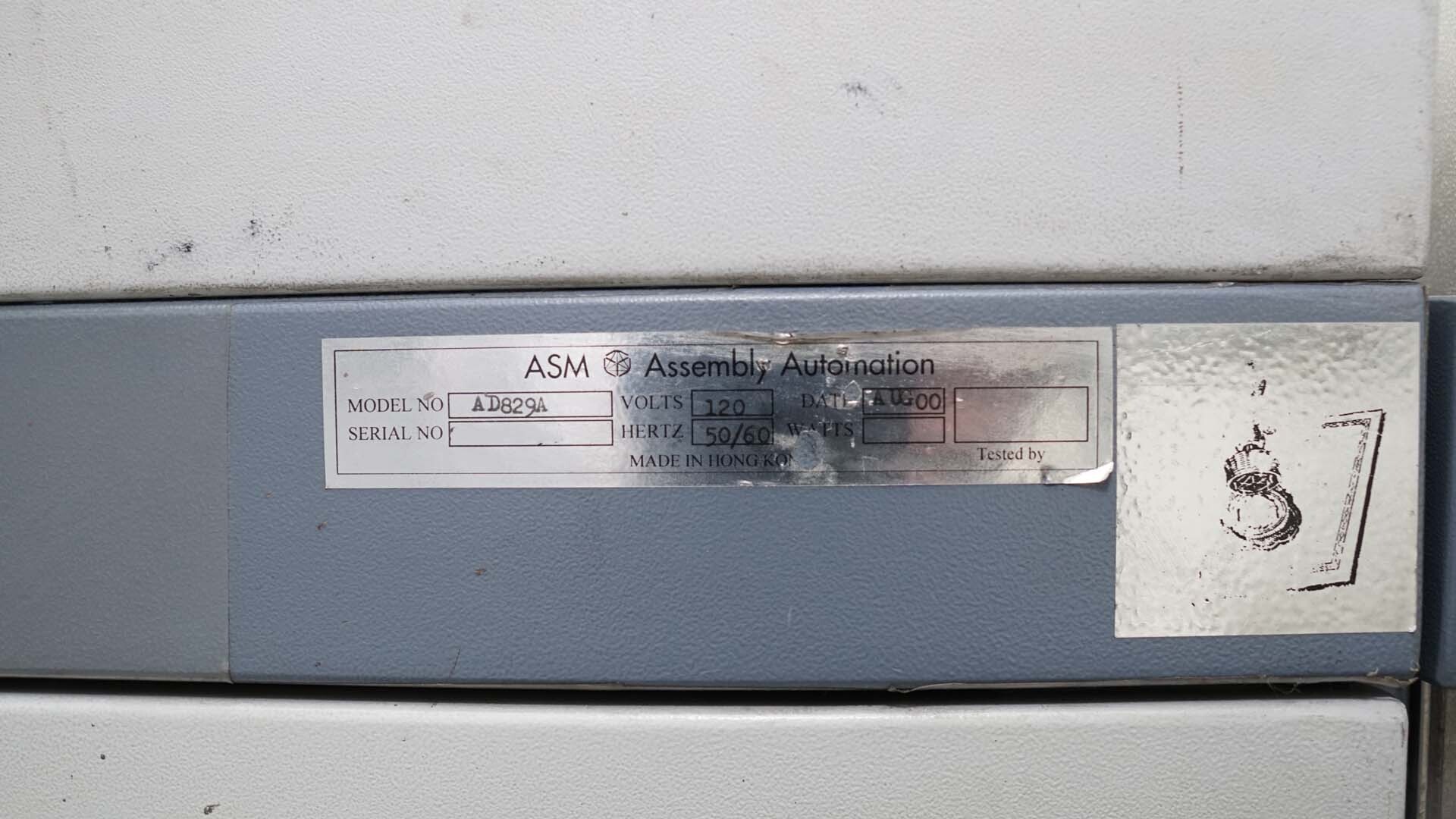

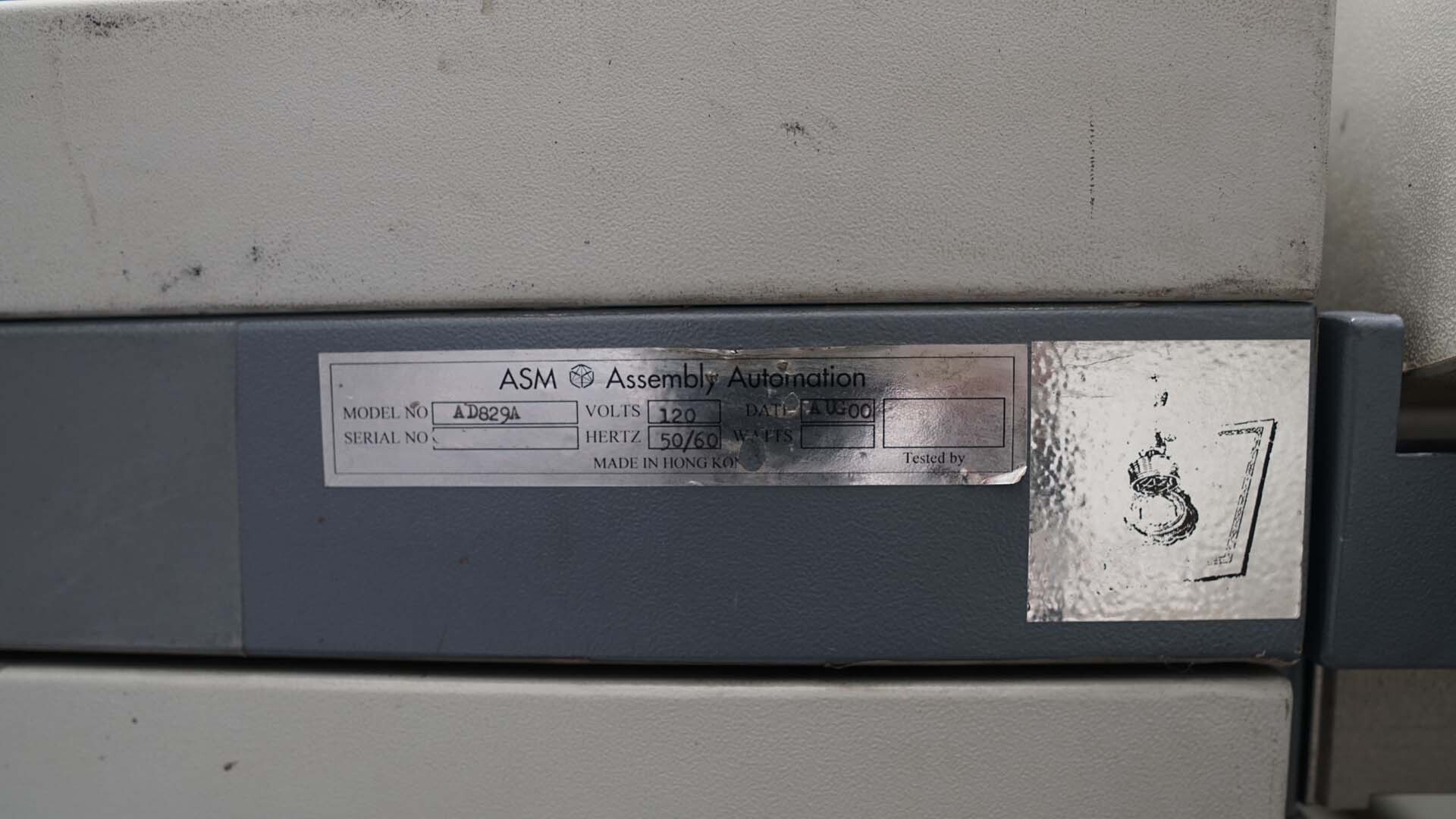

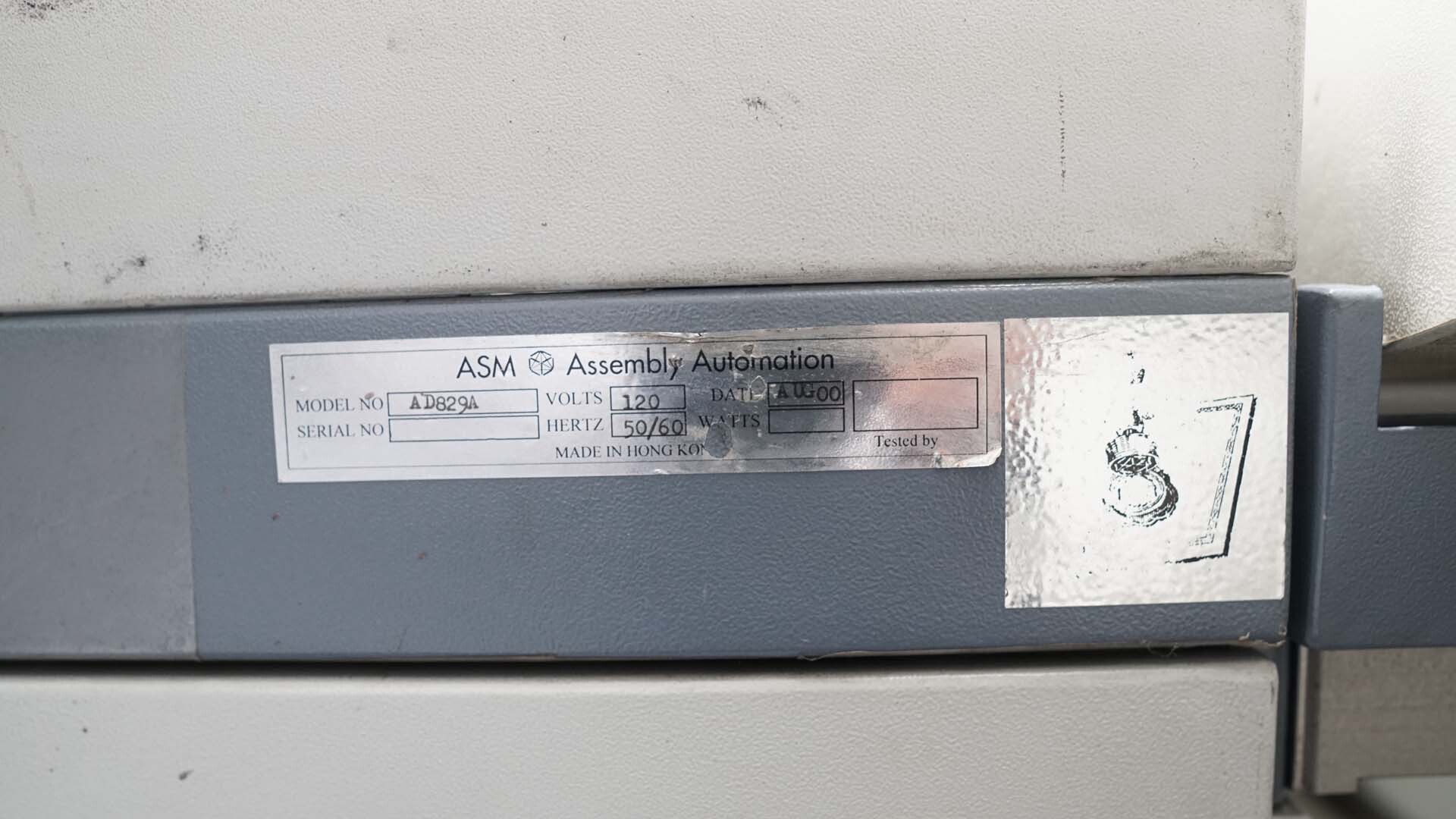

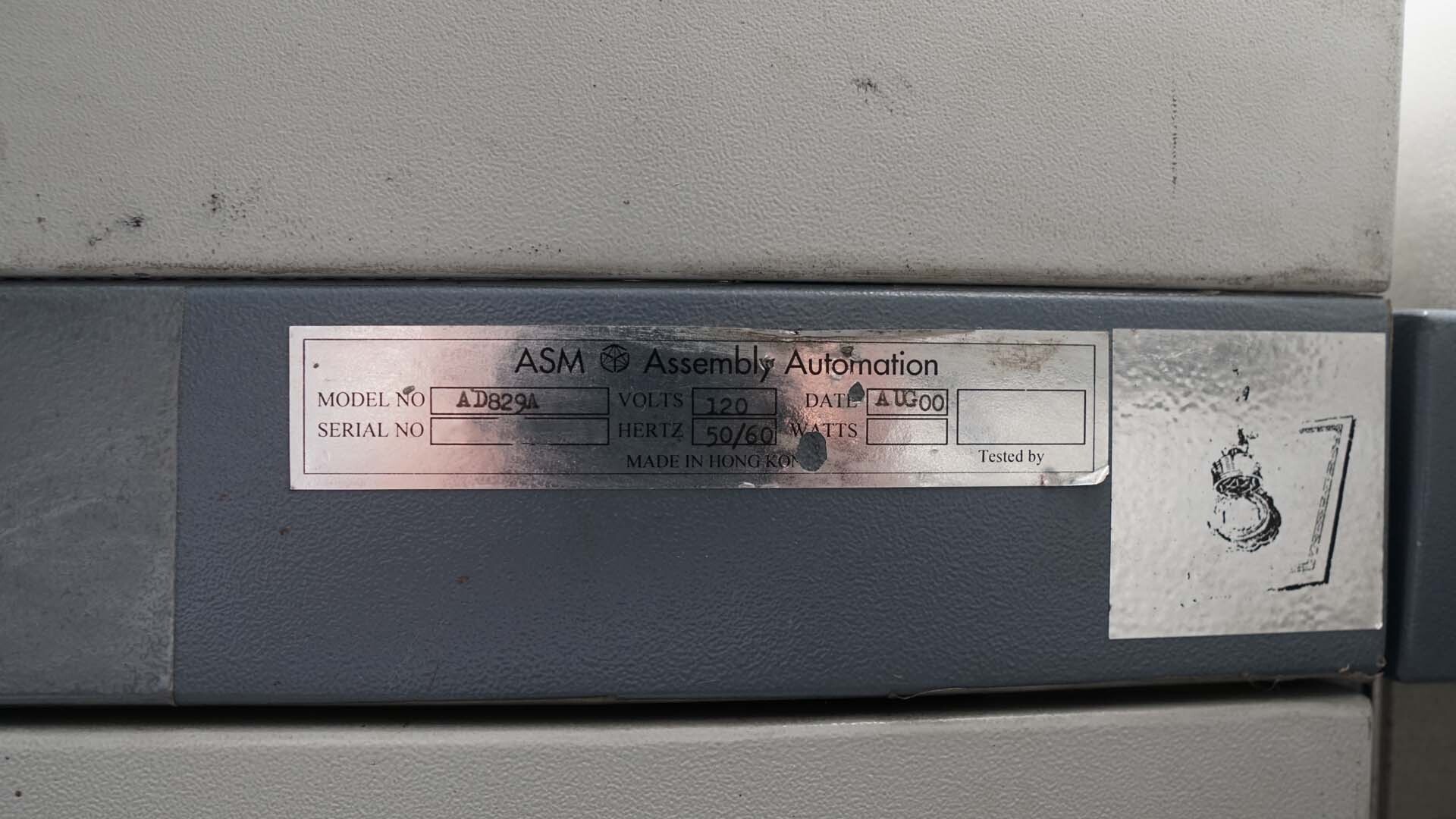

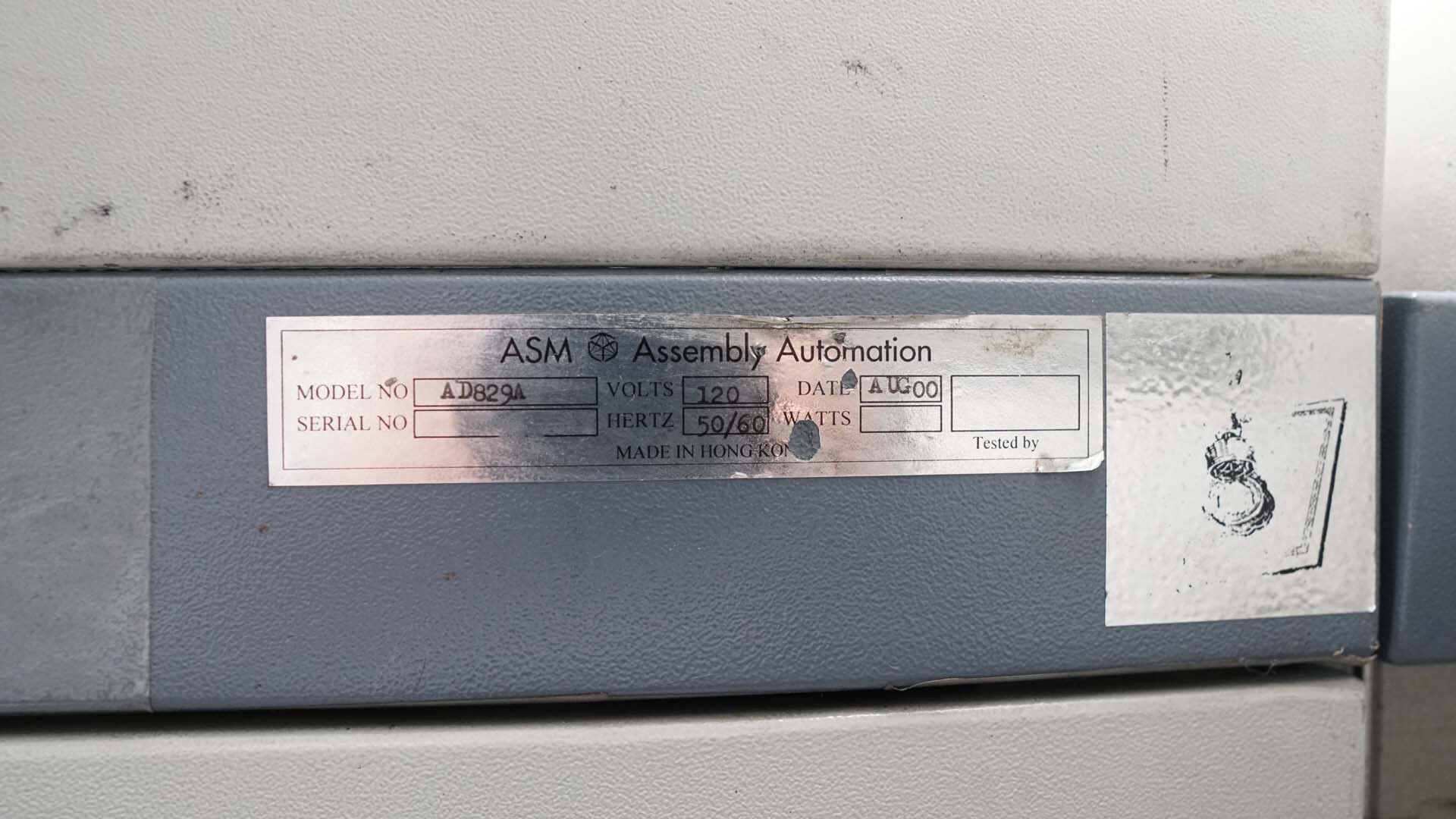

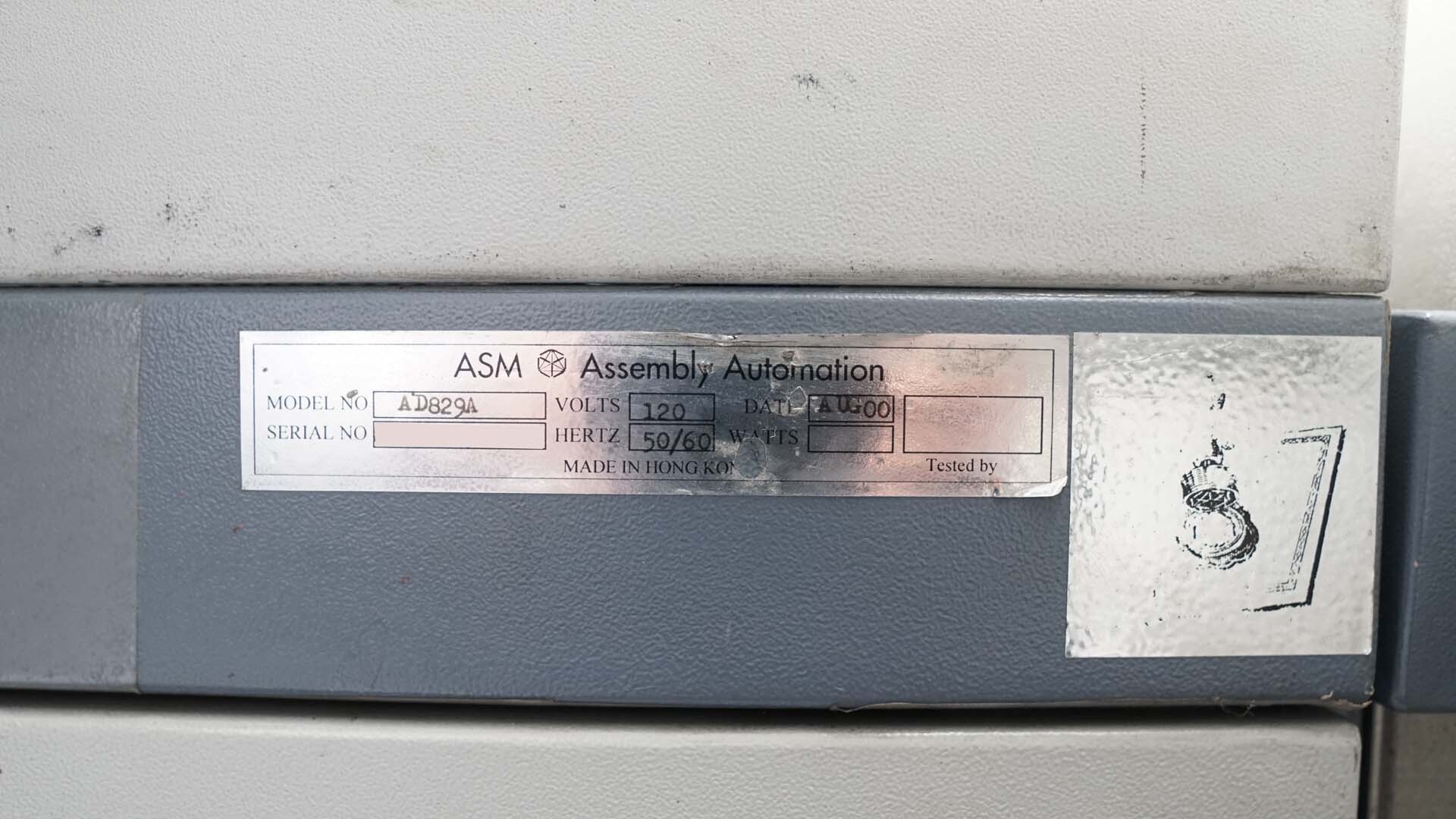

Used ASM AD 829A #293656552 for sale

URL successfully copied!

Tap to zoom

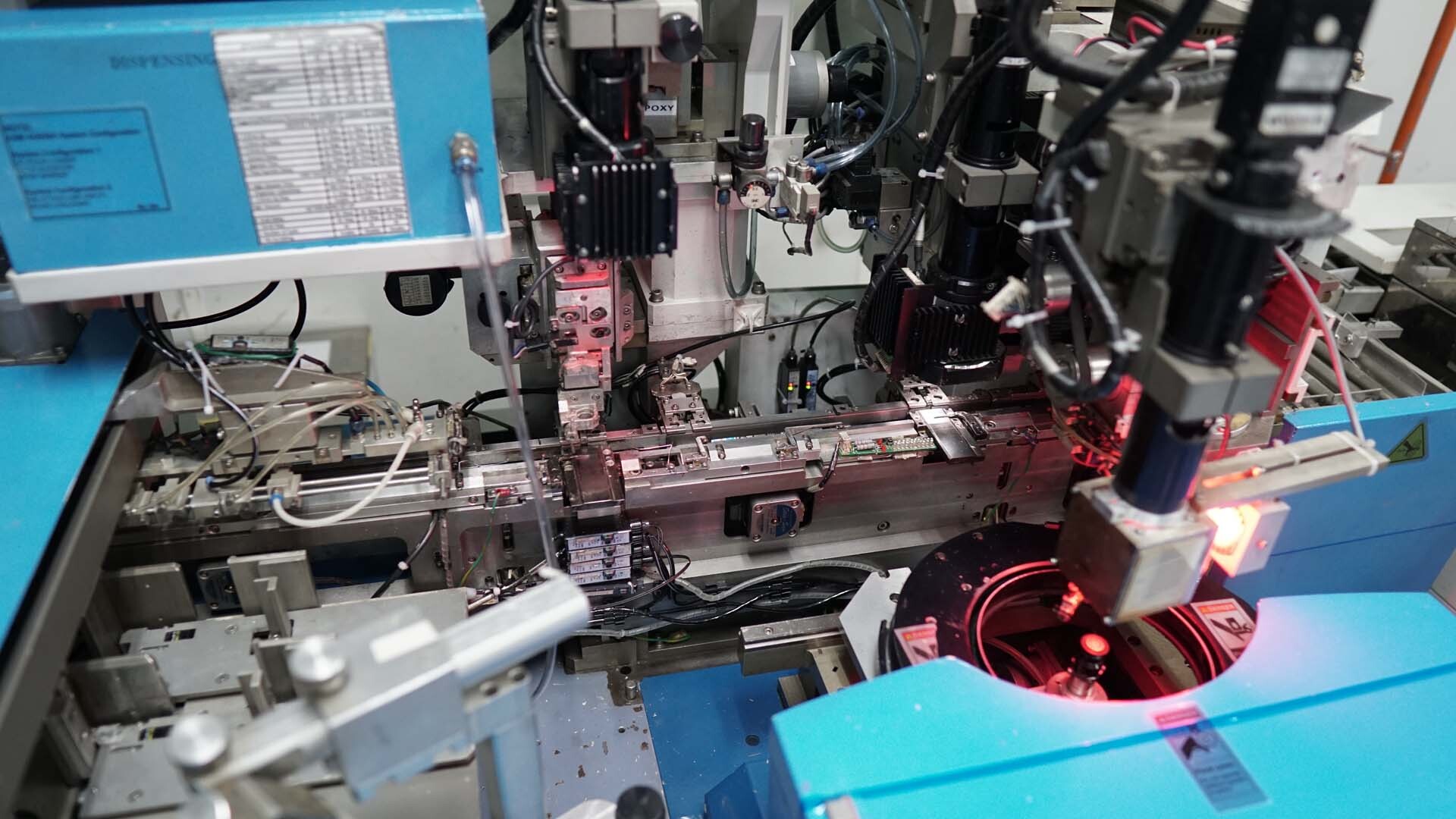

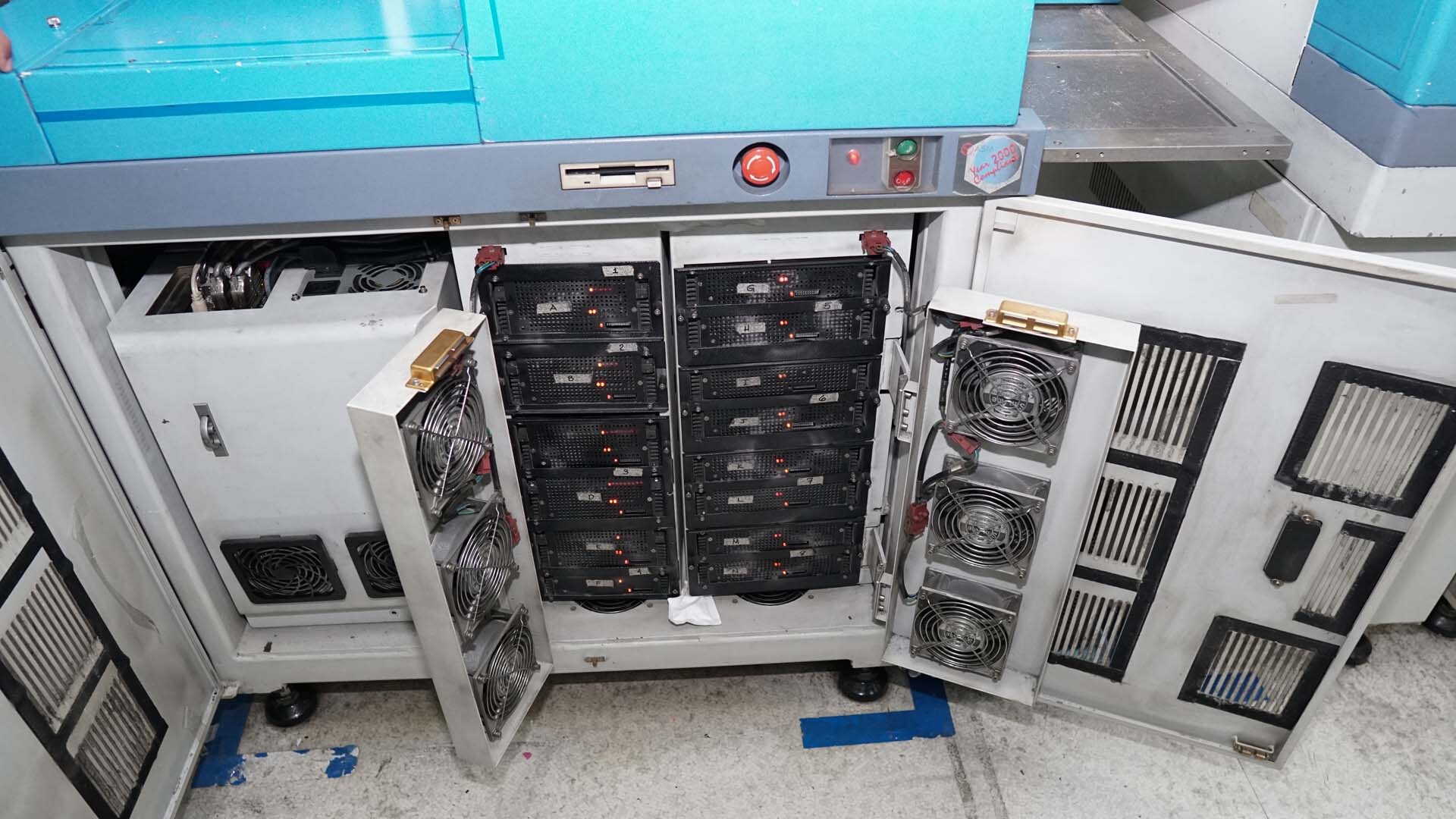

ASM AD 829A is a computerized die attach equipment. The system is a precision die attach tool with a unique design incorporated into a small footprint. It is capable of placing large and small die components onto a substrate in a high-speed, repeatable, and accurate manner. The unit uses a robotic arm with a vacuum-assisted soldering needle, electrical sensing cartridges and a high-precision programmable motion controller. It can be configured to operate with an array of up to 4 die-attach needles so that multiple components can be placed simultaneously. The robotic arm is capable of movement in three axes and has a maximum speed of 600 millimeters per second and a repeatability accuracy of ±25 micrometers. The vacuum-assisted soldering needle is designed for high accuracy, with a maximum tapered tip diameter of 0.15 millimeters. The accuracy of the solder pattern is further enhanced by the electrical sensing cartridges for detecting the presence and position of the die. AD 829A is also equipped with a high-precision programmable motion controller and a die-attach feeder. The motion controller is used to program specific control instructions such as speed, acceleration, strokes, and accelerations. It also provides programmable speed and acceleration tuning for various substrate types. The die-attach feeder supplies components to the die-attach needles, which are then placed onto the substrate surface. Once the placement program is complete, the machine then executes a sequence of welding operations. These welding operations include soldering, fluxing, and bonding. ASM AD 829A die attach tool is designed for many applications and can accommodate a variety of components with different shapes and sizes. Its small footprint makes it an ideal solution for a variety of automated and manual production processes, including set-up, operation, and maintenance. Its high precision and repeatability make it ideal for production and prototyping assembly.

There are no reviews yet