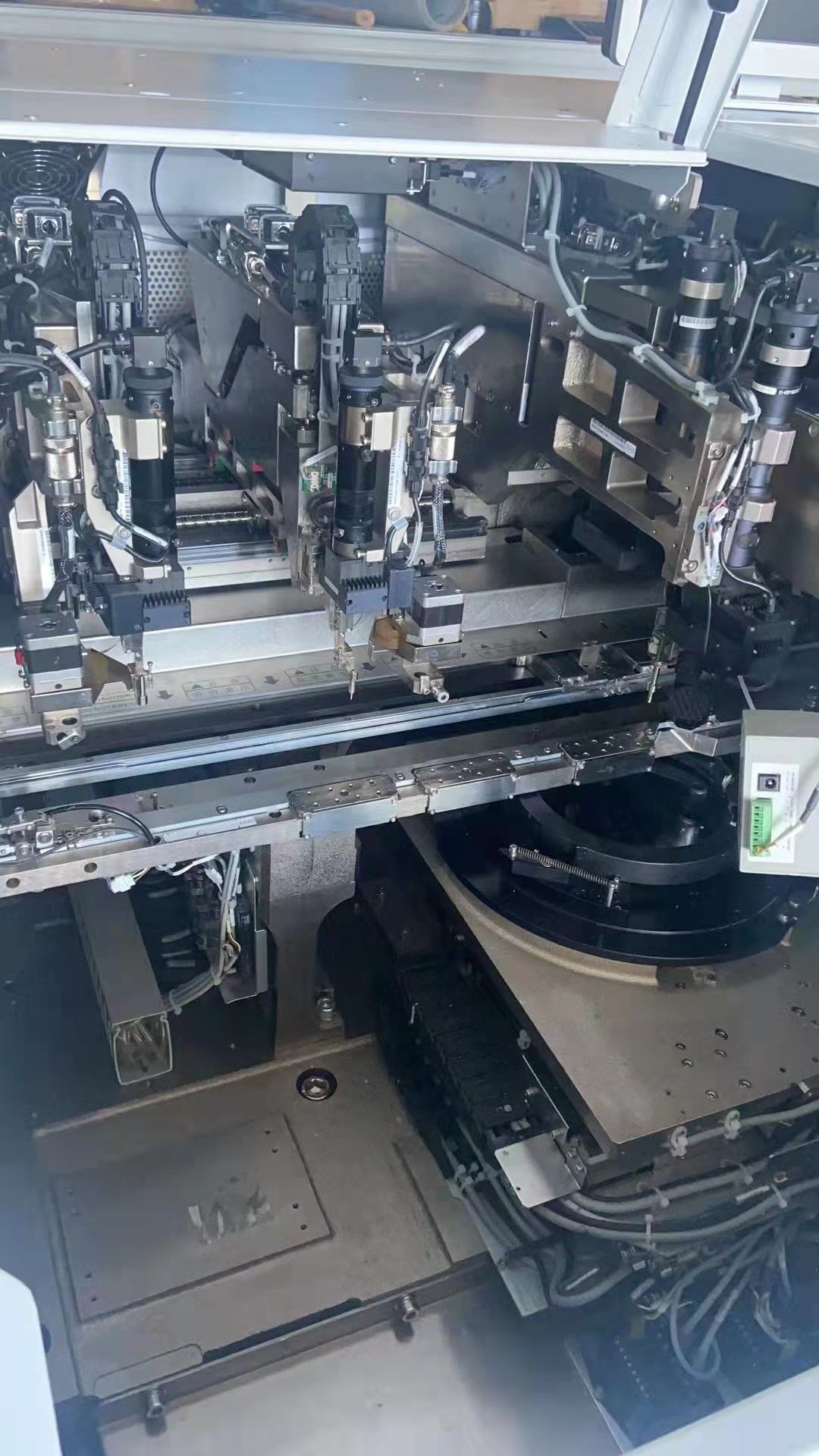

Used ASM AD 830 #293591514 for sale

URL successfully copied!

Tap to zoom

ASM AD 830 is an automated die attacher designed for semiconductor applications. This machine is used to attach multiple dies, typically with a die pitch of 8 mm or less, onto substrates such as leadframes, tape or flex circuits. ASM AD830 is designed for high throughput and is capable of reaching speeds of up to 85 picks per minute. The machine is powered by a Siemens Simatic S7-300 PLC, which allows for fully automated operation with predictive and dynamic adjustments to speed, accuracy and reliability. AD 830 features a dual gantry equipment design, allowing both dies and substrates to be servo-driven and independently controlled. This two-axis system provides high levels of accuracy and repeatability, ensuring that the die is accurately positioned and securely held in place. The gantry unit also features a vision machine to ensure the assurance of a successful pick. The vision tool is equipped with both backlighting and in-die separation monitoring, enabling brightfield and darkfield imaging to identify and track the die substrate accurately. AD830 utilizes a dry double-sided adhesive application for die attachers. This asset is designed to be user-friendly and quick to use, with simple adhesive change-outs and minimal maintenance requirements. The dry adhesive application is also designed for low-tack operation, which ensures that the die is secure but still allows for easy placement when removed from the substrate. The machine is designed to run safely and securely, with safety features such as light curtains, safety matting and safety interlocking. ASM AD 830 features a centralized, easy to access control cabinet, which houses all the necessary electricity and air supply components. The model is also RoHS compliant, and meets UL/IEC 60204-1 safety standards. Overall, ASM AD830 is a highly reliable and efficient die attacher designed for a wide range of semiconductor applications. Its dual gantry equipment and vision system provide accuracy and repeatability, while the dry double-sided adhesive application provides secure yet quick handling of dies. The machine is RoHS compliant and meets UL/IEC safety standards as well, making it a safe and secure choice.

There are no reviews yet