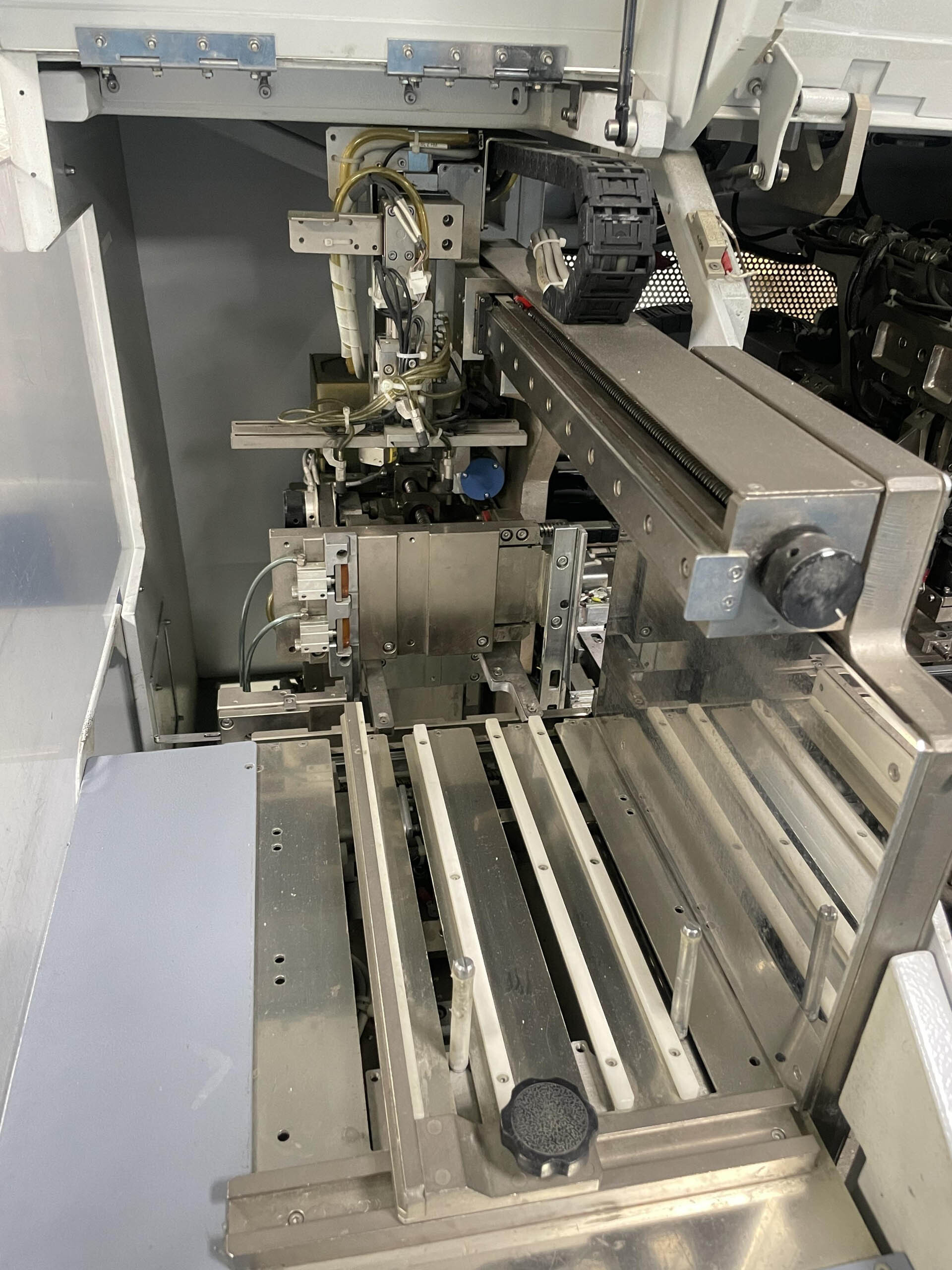

Used ASM AD 830 #293592751 for sale

URL successfully copied!

Tap to zoom

ASM AD 830 is a state-of-the-art die attacher designed to quickly and accurately attach dies to plastic components and printed circuit boards. This advanced equipment features a number of features that make it the ideal solution for high volume production runs with strict quality standards. ASM AD830 is equipped with a reliable PLC control system that automates the die attaching process, providing optimal accuracy and speed. It is capable of attaching over 100 dies per minute, offering excellent capacity for high-speed applications. Additionally, it is equipped with temperature and glue levels sensors that provide precise control over glue levels and temperature, preventing any errors that may occur during the process. AD 830 offers multiple functions to its users. Its image recognition unit helps the machine quickly detect and determine the exact size, shape and position of the die on the component, providing the highest accuracy for die placement. For that reason, it is ideal for applications where exact positioning and alignment are essential. Furthermore, its advanced automation processes enable the adjustment of the flow rate of glue and the blade pressure, greatly reducing errors and improving the quality of final results. AD830 comes with an intuitive graphical user interface combined with a touch screen, allowing the user to easily configure parameters and all other aspects of the tool. This user-friendly interface and easy-to-follow instructions make the asset ideal for operators who require minimal training to learn how to operate the model. Overall, ASM AD 830 is a powerful die attacher designed to provide impressive speed, accuracy and efficiency when attaching dies to printed circuit boards and plastic components. Its automation, image recognition, and adjustment capabilities make it ideal for various mass production applications, guaranteeing excellent results and quality.

There are no reviews yet