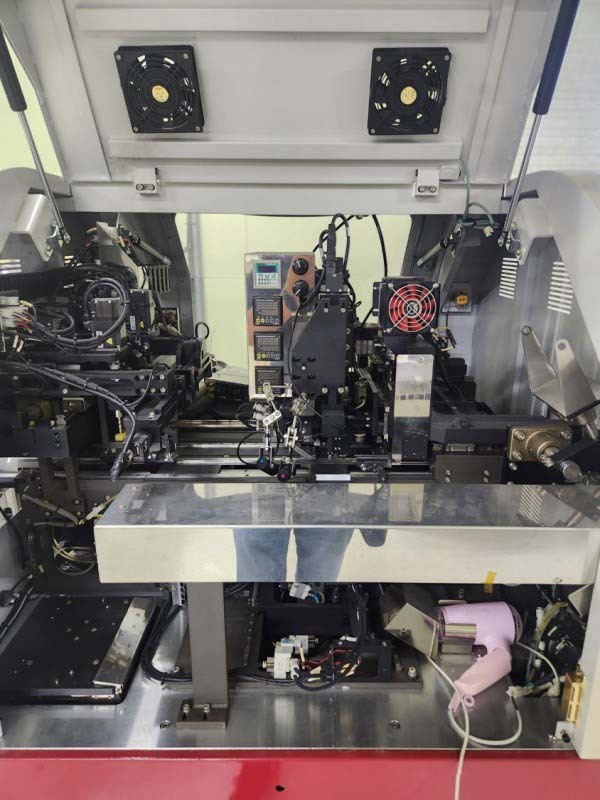

Used ASM AD 830 #9190548 for sale

URL successfully copied!

Tap to zoom

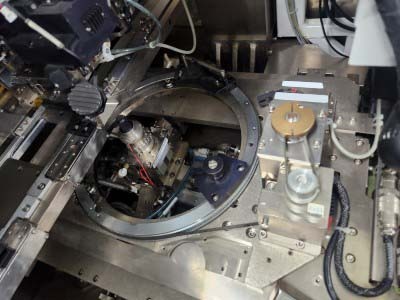

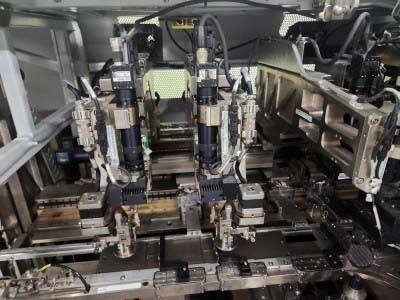

ASM AD 830 is an automated die attacher designed to rapidly and accurately attach dies to printed circuit boards (PCBs). It is equipped with a patented precision clamp equipment which maintains die placement accuracy of up to +/- 0.050" cleanly placing both large and small die onto the PCB without damage. The system also utilizes a special die orientation fixture which uses a fixed tool and a rotating arm to accurately position the die onto the PCB. ASM AD830 has a self-centering placement head which accurately locates the die onto the board. This feature eliminates the need for hand adjustment and increases accuracy and speed. AD 830 is also designed to work with multiple die sizes, shapes, and weights. It can also accommodate both quick-change and standard die clamping systems. It also has a built-in inspection camera and servo motor controlled alignment unit for precise die placement. The machine is designed for in-line production operations with maximum PCB processing speed of up to 30 parts per minute. The output of the tool is adjustable, meaning that its speed and accuracy can be adjusted according to the needs of the user. Furthermore, the asset can be integrated with other in-line machines such as pick-and-place, thermo-sonic die bonding, and selective soldering machines. AD830 has both a manual and an automated loading station. The manual station is equipped with a vacuum model for quick loading and unloading of dies. The automated station has a built-in vision equipment which is used to inspect placed die. It can also place die onto the board and adjust rotation and placement offsets for accurate alignment. Overall, ASM AD 830 is a reliable, cost-effective die attacher that is designed to meet the high-precision, high-speed requirements of automated assembly lines. It is equipped with a precision clamping station which ensures high levels of accuracy while also maintaining speed. Additionally, the system boasts a versatile die orientation fixture and a built-in inspection camera for superior component placement.

There are no reviews yet