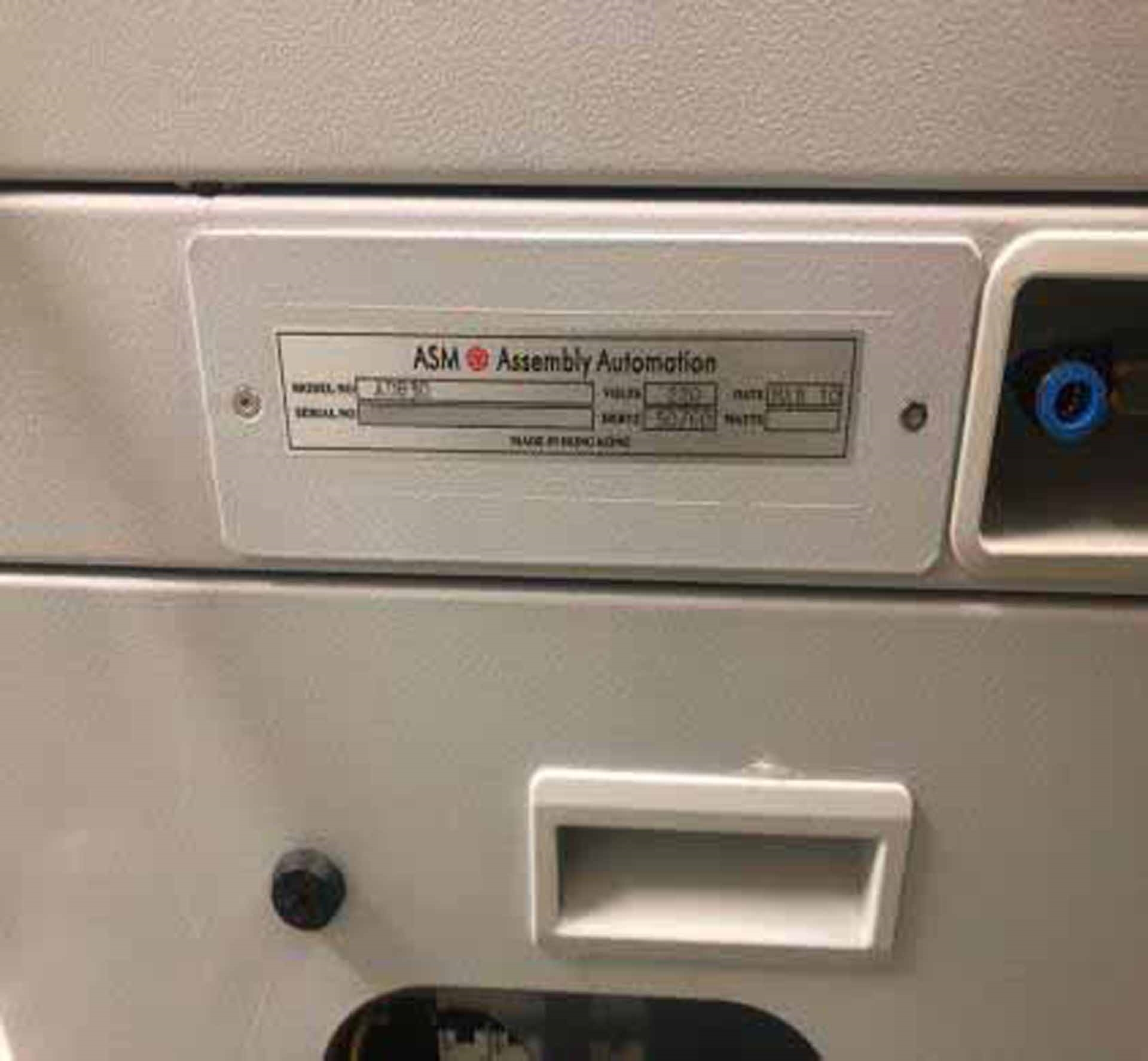

Used ASM AD 830 #9235234 for sale

URL successfully copied!

Tap to zoom

ID: 9235234

Vintage: 2010

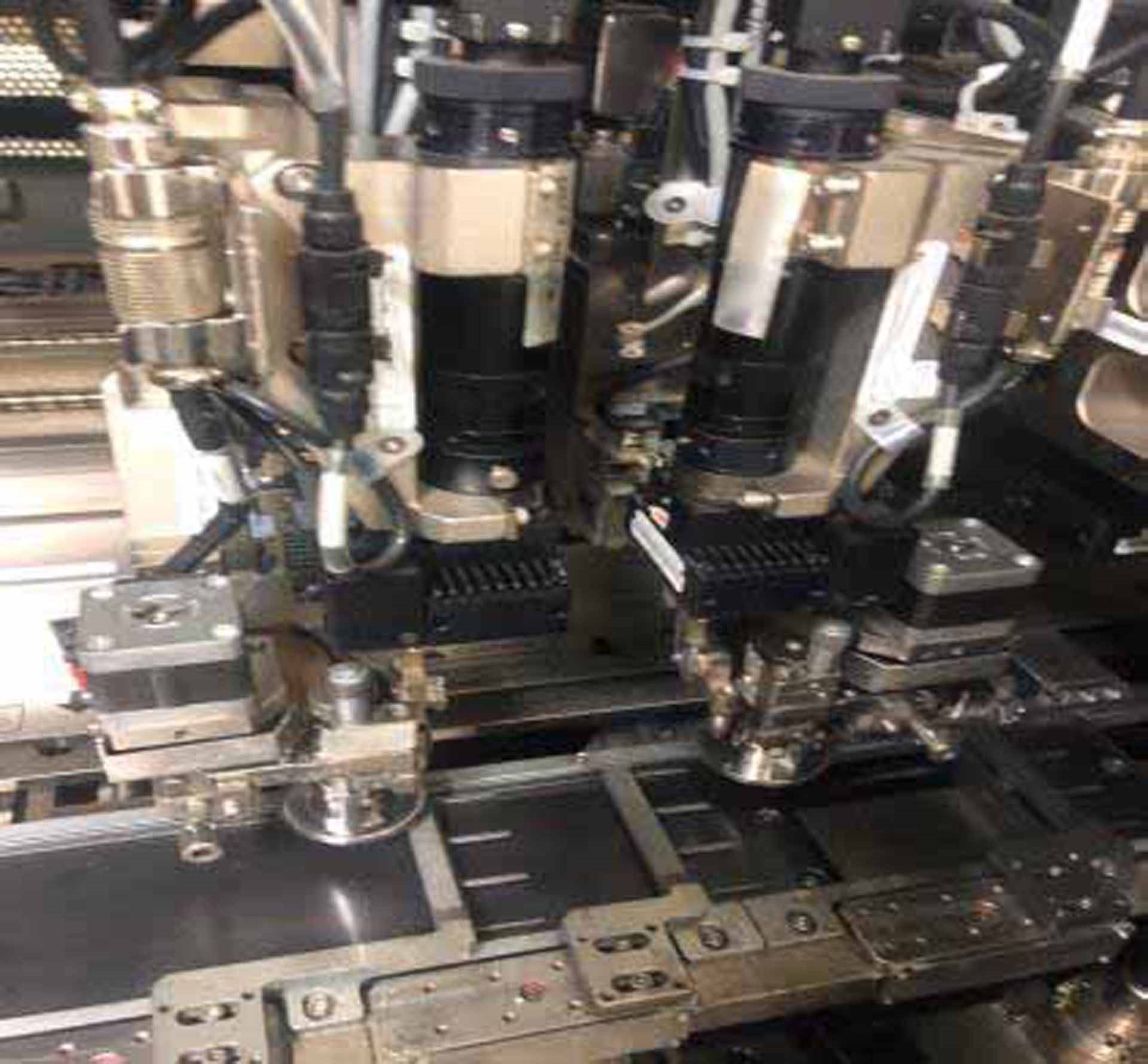

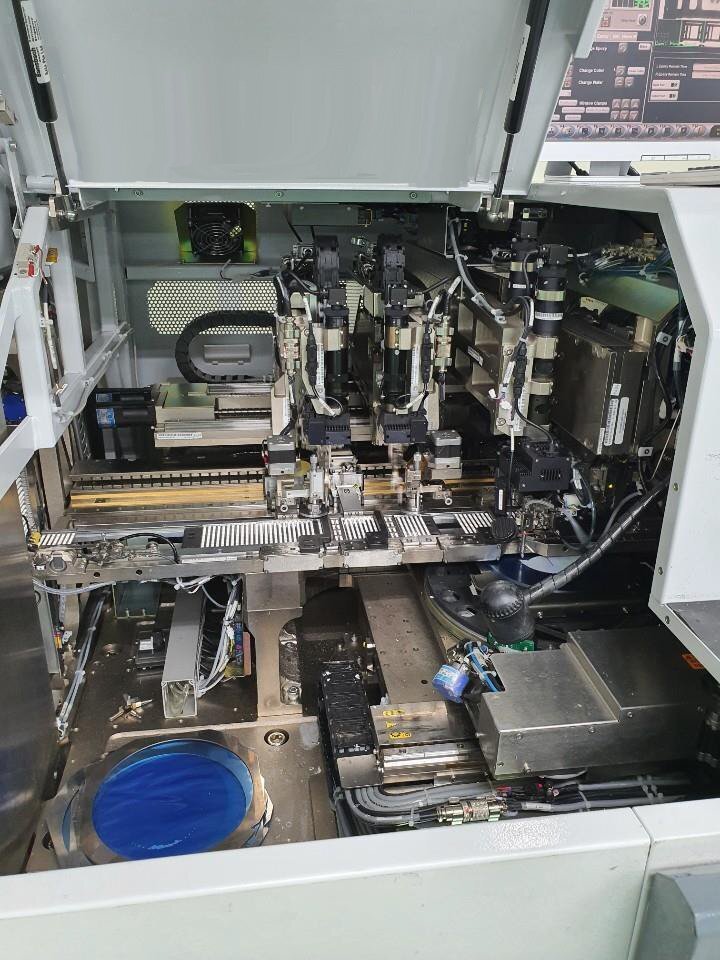

Die bonder, parts machine

Wafer ring type: Expander

Dispenser type: Dotting

Stamping type: Dotting

2010 vintage.

An ASM AD 830 die attacher is an automated equipment designed to provide fast and consistent placement of parts on substrates. It is used in a wide range of industries such as electronics, automotive, medical, and aerospace. The system is designed to accommodate most die placement requirements. ASM AD830 is a computer-controlled unit that is able to place die into substrates in a precise and consistent manner. It is equipped with a variable frequency motor to provide greater control in managing die placement speed and positioning. The motor is capable of placing any size die accurately at a speed up to 1,500 parts per hour. The feeder is equipped with a vision machine which is used to detect the positioning of the die and ensure precise placement. AD 830 includes a variety of features to assist with die placement accuracy. The first is a tooling tool that allows for the quick and efficient switching of die from the feeder bed. This feature increases throughput, allowing for faster processing times. The second is a process-monitoring asset which helps ensure accuracy by checking the die placement on a continuous basis. AD830 is constructed from durable materials to ensure a long-lasting performance. The die feeder is designed to resist shock and vibration, while the vision model is protected from dust and dirt. The equipment can be operated in a wide range of temperatures, from -30 degrees Fahrenheit to 299 degrees Fahrenheit. As an automated system, ASM AD 830 can offer cost savings in labor costs and downtime due to equipment failure. The reduced downtime allows for higher productivity and reduced costs, providing a positive return on investment. Overall, ASM AD830 die attacher is an automated unit designed for reliable and accurate die placement. It offers high levels of speed, accuracy and control to ensure each component is attached correctly and quickly. The machine is robust, durable and requires little maintenance, making it a convenient and cost-effective solution for many industries.

There are no reviews yet