Used ASM AD 830 #9250584 for sale

URL successfully copied!

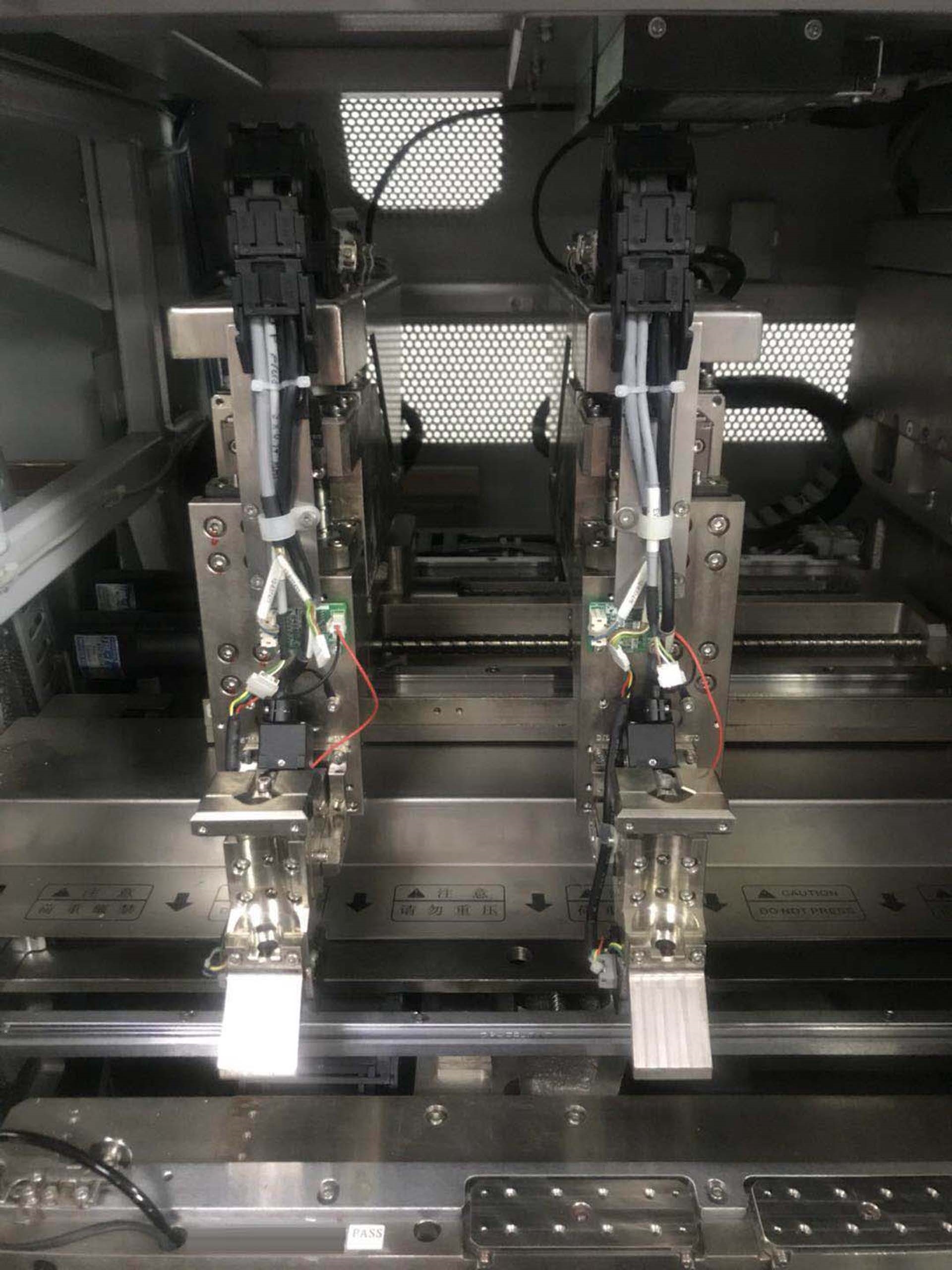

Tap to zoom

ASM AD 830 is an automated die attacher, designed to attach die-cut pieces of material to prepress printing forms. This equipment uses an automated adhesive system and has a high capacity for adhering die-hammer-cut materials in an efficient manner. ASM AD830 produces projects with a minimal amount of manual labor, resulting in improved production through reduced labor costs. At the heart of AD 830 is a high-resolution camera capable of accurately recognizing die shapes and material types. This camera is integrated with a vacuum actuated press, a pre-determined vacuum level and a four-roller advance feeder. The vacuum level enables the press to adhere the material accurately and securely. The four-roller feeder creates a uniform-material flow across the width of the press, ensuring an even attachment. AD830 is highly flexible and can be programmed to adhere multiple items on each die. It is capable of detecting material thickness adjustment and can be set to memorize settings for each die. To maintain a clean workspace, an air knife unit is available to remove the excess adhesive from the die-cut material. The press utilizes a set of stencils which can be changed to accommodate different shapes and sizes. This allows users to quickly and easily create die cut pieces which can then be added to their forms. ASM AD 830 stencils also allow the press to double as a stamping press, using heat energy instead of adhesive to affix the die-cut pieces. ASM AD830 also features accurate repeat registration. An encoder machine is integrated into the press, which enables users to track each impression across the substrate in order to maintain precise repeat criteria. AD 830 has a maximum working speed of 18,000 impressions per hour, and is compatible with substrates up to 16mm thick. This makes it perfect for many printing projects where there is a need for accurate die-cutting or a need for quick production. AD830 is a great choice for those looking to increase efficiency in their workflow while still maintaining a high degree of accuracy.

There are no reviews yet